Cutter shaft structure for paper cutter of toilet paper folding machine

A paper cutter and folding machine technology, applied in metal processing and other directions, can solve the problems that affect the processing and finished product quality, increase the manufacturing cost of paper cutters, and have particularly high requirements, so as to delay labor and time, prolong service life, and reduce use. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples.

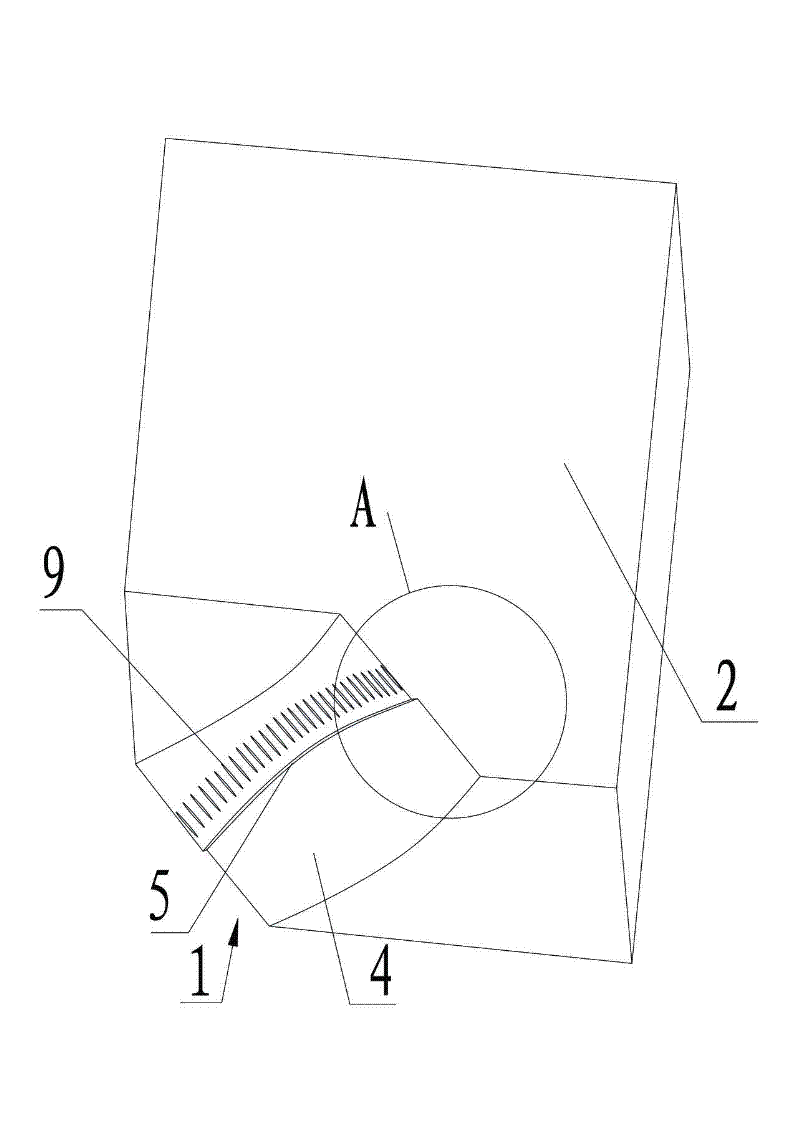

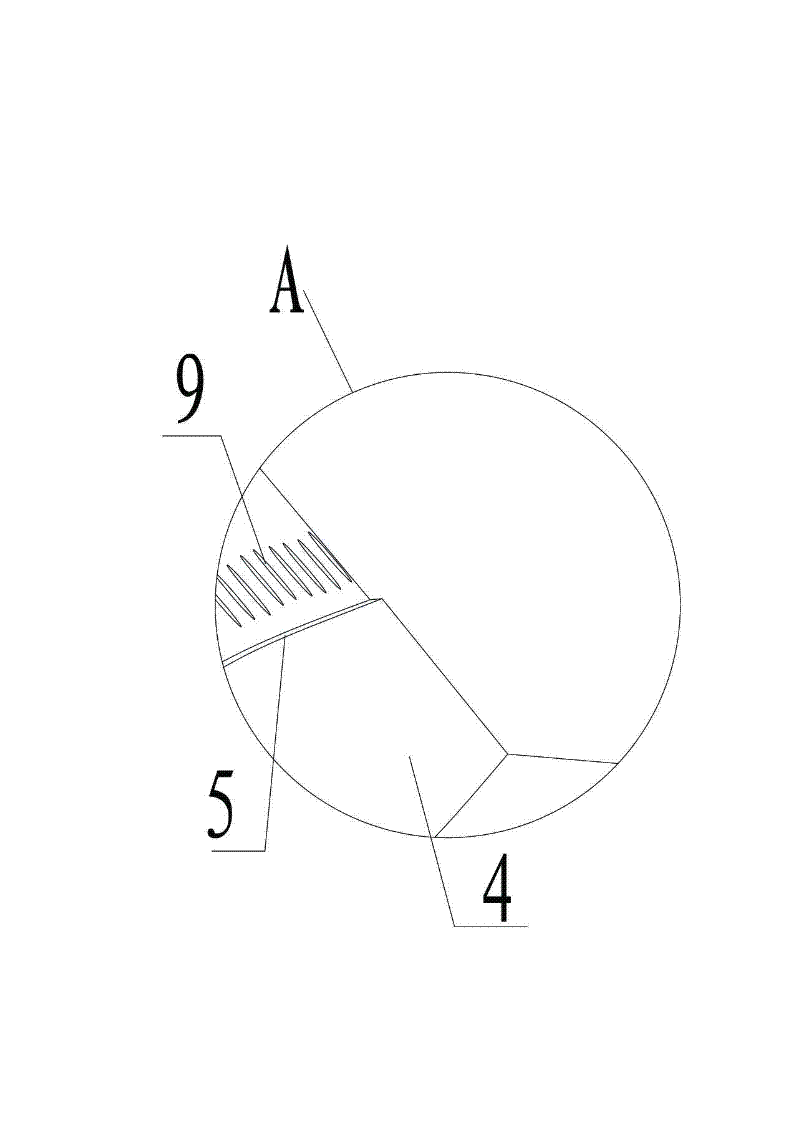

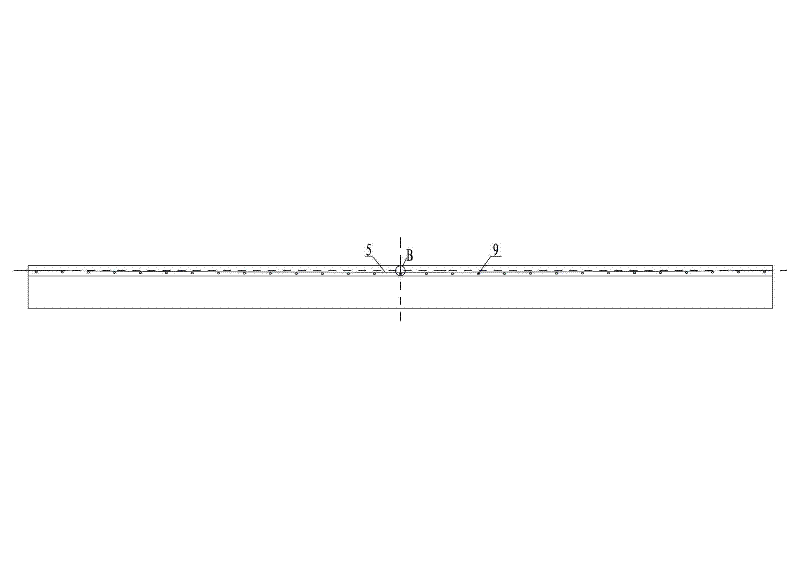

[0034] See attached figure 1 to attach Figure 15 As shown, the paper cutter shaft structure of the toilet paper folding machine described in this embodiment includes a knife shaft body 2, wherein the paper cutter installation position 1 of the knife shaft body 2 is in close contact with the paper cutter blade surface The combined surface is an oblique cut surface along the length direction of the knife shaft body, and the oblique cut surface forms a curved first inferior arc surface 4 inwardly, and the two sides of the vertical centerline of the first inferior arc surface 4 are symmetrical to each other; the paper cutter The surface of the installation position 1 and the back of the paper cutter is the second inferior arc surface 5 that makes the back of the paper cutter form an arched back, and the two sides of the vertical center line of the second inferior arc surface 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com