Method for making non-formaldehyde laminated veneer lumber from gum wood

A technology of laminated veneer lumber and eucalyptus, which is applied to the jointing of wooden veneers, manufacturing tools, and wood layered products, etc., can solve problems such as warping and deformation, and achieve structures that are not easy to warp, high use value, Good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of method of making formaldehyde-free laminated veneer with eucalyptus wood, comprises following operation:

[0016] ①, Medium and small-diameter eucalyptus logs are peeled and cut to make eucalyptus veneers with a thickness of 2.4mm, a length of 1270mm, and a width of 320mm or 640mm;

[0017] ②, the eucalyptus veneer is dried in a dryer, and the moisture content of the veneer is controlled below 12%;

[0018] ③, put the veneer in a hot press for softening treatment, the temperature is 110°C, the pressure is 0.8mpa, and the time is 2min;

[0019] ④, use starch adhesive on veneer after softening treatment, and glue it on the glue machine, and the amount of glue is controlled at 300g / square meter on both sides; the proportion and preparation of starch adhesive are in the patent number: CN201010171082.8 documented in the patent documents.

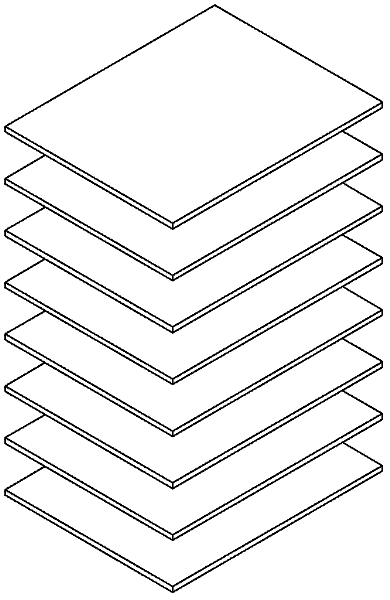

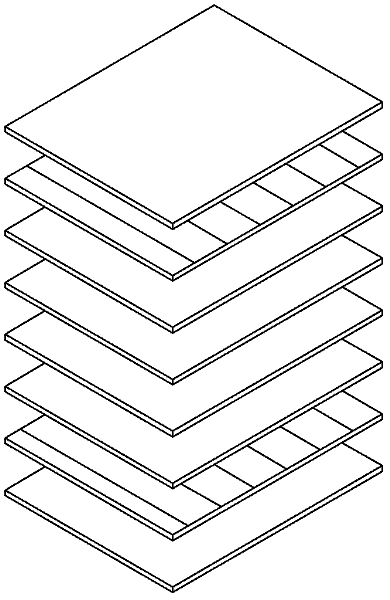

[0020] ⑤, Blank assembly: the glued eucalyptus veneer is made into a group of 8 layers, such as figure 1 As sh...

Embodiment 2

[0024] Embodiment 2: a kind of method of making formaldehyde-free laminated veneer with eucalyptus wood, comprises following operation:

[0025] ①, Medium and small-diameter eucalyptus logs are peeled and cut to make eucalyptus veneers with a thickness of 3.0mm, a length of 1300mm, and a width of 320mm or 640mm;

[0026] ②, the eucalyptus veneer is dried in a dryer, and the moisture content of the veneer is controlled below 12%;

[0027] ③, Put the veneer in a hot press for softening treatment, the temperature is 125°C, the pressure is 1mpa, and the time is 1min;

[0028] ④, apply starch adhesive to the veneer after softening treatment, and glue it on the glue machine, and the amount of glue is controlled at 320g / square meter on both sides; the proportion and preparation of starch adhesive are in the patent number: CN201010171082.8 documented in the patent documents.

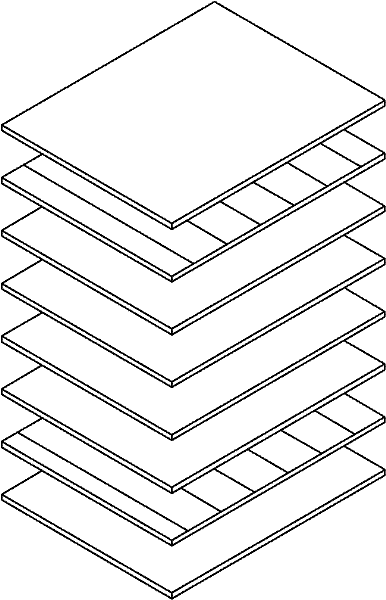

[0029] ⑤, Blank assembly: the glued eucalyptus veneer is made into a group of 8 layers, such as figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com