System and method for guaranteeing oxygen supply on ship

A technology for ships and oxygen supply, which is applied in the direction of ships, ship parts, ship construction, etc., to reduce the buffer volume and improve the utilization rate of gas cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

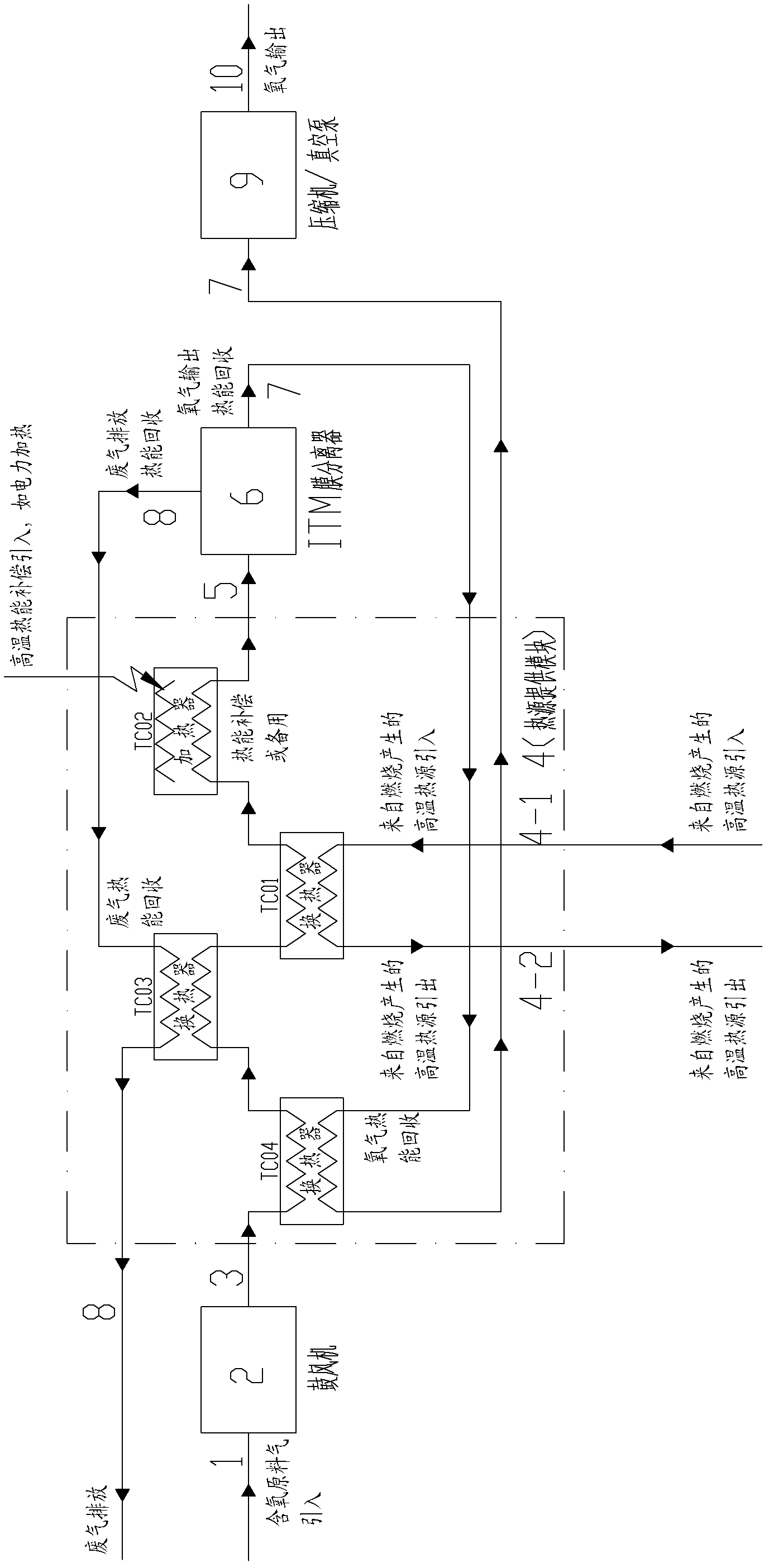

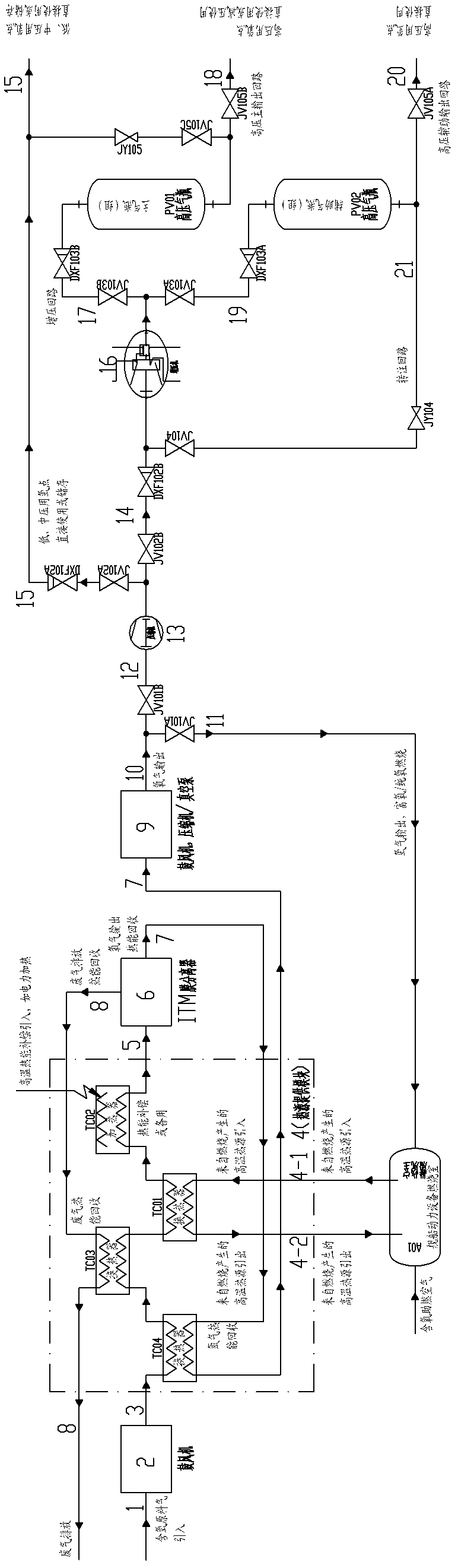

[0038] The following is attached Figure 1-4 The embodiment of the present invention is described further, but does not limit the present invention.

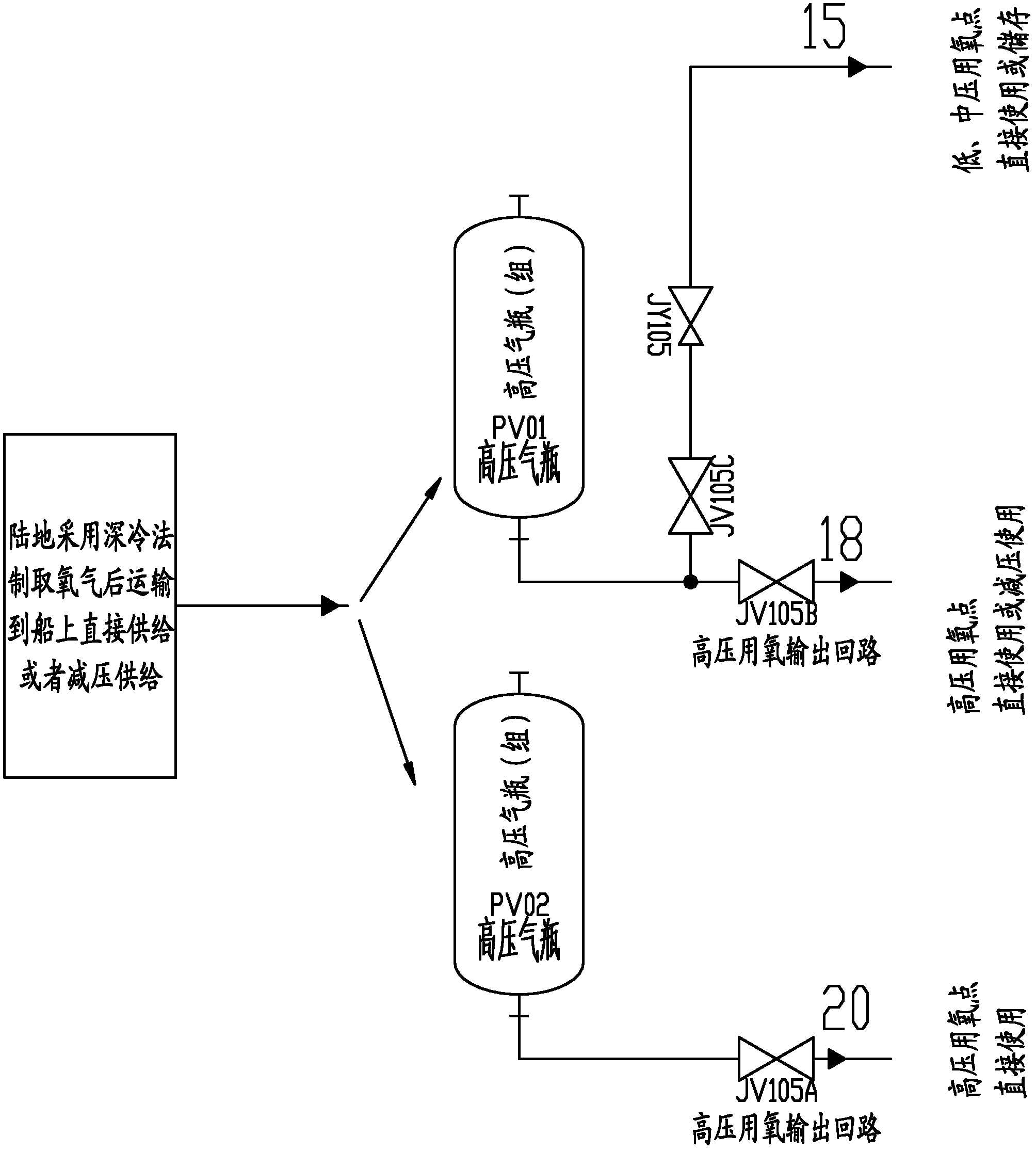

[0039] as attached figure 1 , the oxygen-containing gas is introduced into the blower 2 from the pipeline 1 through the primary filtration described in the known technology (typically, such as filtering to the particle accuracy of figure 1 The part included in the dotted line) is heated to the required separation temperature, and the heat source supply module 4 preferably uses the temperature generated by the main heat exchanger TC01 from various combustion processes to heat the raw gas, and the high-temperature flue gas is introduced from the pipeline 4-1 , returns from the pipeline 4-2; of course, various forms of heating methods can also be used, such as electric heater TC02 to heat the feed gas to a predetermined separation temperature and then enter the membrane separator 6, and the high-temperature feed gas is self-connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com