Method for producing crocin with higher than 95% purity from gardenia

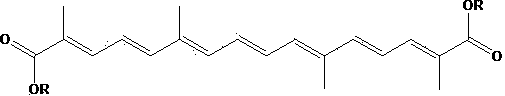

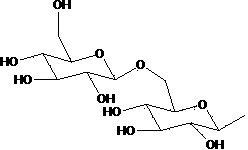

A technology of saffron and gardenia, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems that are difficult to realize industrial production and affect the application of saffron active substances, achieve low cost and improve column efficiency , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Extraction: crush 1 kg of dried gardenia fruits to 10-40 mesh, soak in 8-15 kg of pure water at room temperature for 1 hour, then percolate at an appropriate flow rate, share 25-35 kg of pure water for extraction, 4 After 8 hours of percolation and extraction, extract A was obtained.

[0023] 2. Microfiltration: Pass the extract A through a 0.2-1 micron ceramic membrane to obtain a clear filtrate B.

[0024] 3. Sample adsorption: use 3 sections of ZT-02 macroporous adsorption resin column, each section of 70ml, the clarified filtrate B is first adsorbed on the first section of the column, when the effluent is reddish, in the first section of the column Connect the second column to the end, and continue to adsorb until the effluent of the second column is reddish, string the third column C at the end of the second column, until the effluent of column C is reddish, remove column C . Re-attach column D to the end of the second section of the column, follow the same method ...

Embodiment 2

[0029] 1. Extraction: crush 10 kg of dried gardenia fruits to 10-40 mesh, soak in 80-150 kg of pure water at room temperature for 1 hour, then percolate at an appropriate flow rate, share 250-350 kg of pure water for extraction, 4 After 8 hours of percolation and extraction, extract A was obtained.

[0030] 2. Microfiltration: Pass the extract A through a 0.2-1 micron ceramic membrane to obtain a clear filtrate B.

[0031] 3. Sample adsorption: use 3 sections of ZT-02 macroporous adsorption resin column, each section of 1000ml, the clarified filtrate B is first adsorbed on the first section of the column, until the effluent is reddish, in the first section of the column Connect the second column to the end, and continue to adsorb until the effluent of the second column is reddish, string the third column C at the end of the second column, until the effluent of column C is reddish, remove column C . Re-attach column D to the end of the second section of the column, follow the same...

Embodiment 3

[0036] 1. Extraction: crush 100 kg of dried gardenia fruits to 10-40 mesh, soak in 800-1500 kg of pure water at room temperature for 1 hour, then percolate at an appropriate flow rate, share 2500-3500 kg of pure water for extraction, 4 After 8 hours of percolation and extraction, extract A was obtained.

[0037] 2. Microfiltration: Pass the extract A through a 0.2-1 micron ceramic membrane to obtain a clear filtrate B.

[0038] 3. Sample adsorption: use 3 sections of ZT-02 macroporous adsorption resin column, each section of 10 liters, the clarified filtrate B is first adsorbed on the first section of the column, until the effluent is reddish, in the first section of the column Connect the second column to the end, and continue to adsorb until the effluent of the second column is reddish, string the third column C at the end of the second column, until the effluent of column C is reddish, remove column C . Re-attach column D to the end of the second section of the column, follow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com