Mg-Al hydrotalcite lubricating and antifriction material prepared by using magnesite and method

A technology of anti-friction material and magnesite, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of non-environmental protection and high cost, and achieve the effects of environmental protection, low cost, and excellent lubrication-anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

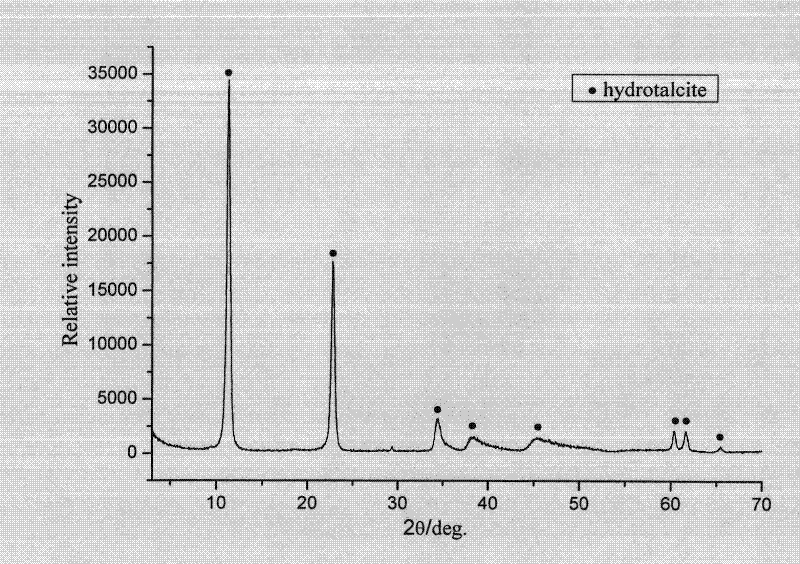

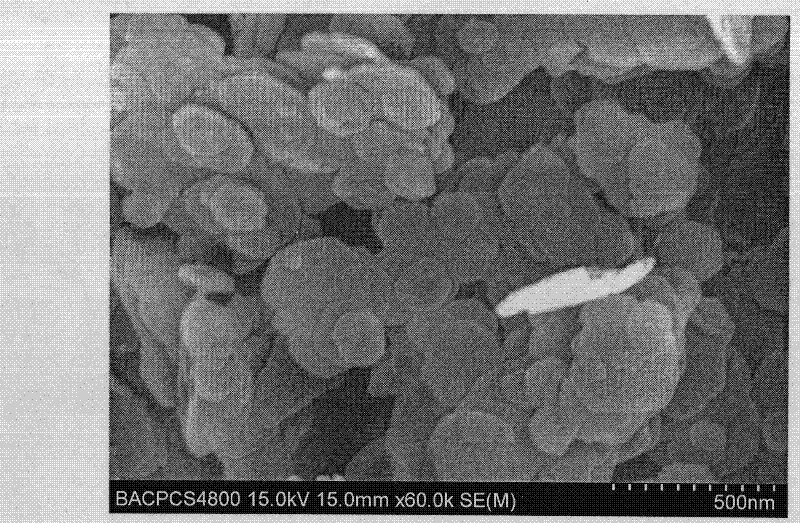

Image

Examples

Embodiment 1

[0030] In the present embodiment, the specific steps for preparing Mg-Al hydrotalcite lubricating-friction-reducing material with natural magnesite are:

[0031] 1) Prepare powder raw materials: use grinding equipment to grind, pass through a 200-mesh sieve, and the particle size of the obtained powder is: the mass of -200-mesh particles accounts for 98.5% of the total mass; the mass of +200-mesh particles accounts for 1.5% of the total mass.

[0032] 2) The natural magnesite after grinding and sieving is mixed with aluminum nitrate and nitric acid in the following ratio to make solution I:

[0033] Magnesite: aluminum nitrate = 3.0: 1 (molar ratio)

[0034] Magnesite: nitric acid = 1: 2.0 (molar ratio)

[0035] Magnesite: aluminum nitrate: nitric acid = 3:1:6

[0036] (3) Move the solution I into an airtight container, and use a magnetic stirrer to continuously stir for 5.5 hours at a temperature of 75° C., and control the rotation speed at 25-30 r / min to obtain solution II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com