Device for testing adhesion between asphalt and aggregate

A test device and adhesion technology, applied in the direction of measuring devices, flow characteristics, analysis materials, etc., can solve the problems of time-consuming, difficult to grasp, and difficult to control heating temperature, etc., to achieve good results, save time, and reduce test costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

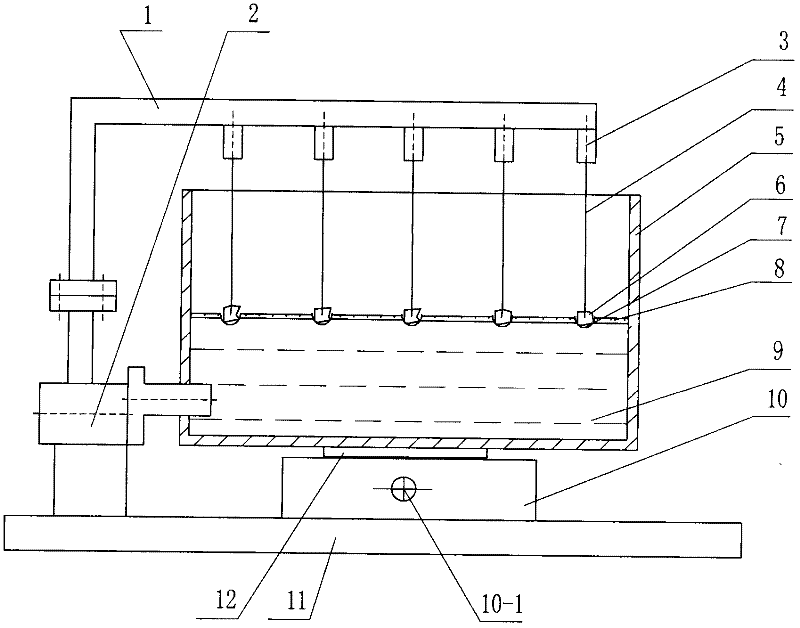

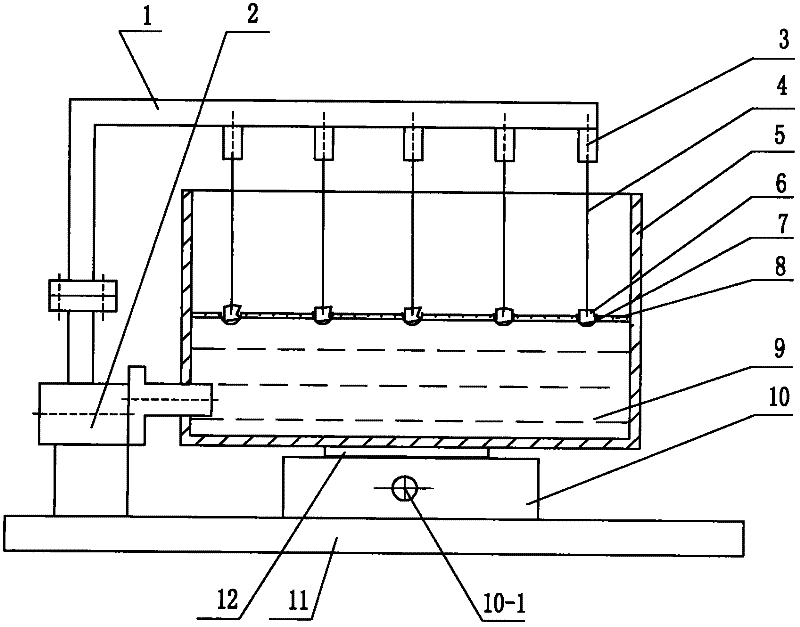

[0013] exist figure 1 Among them, the asphalt and aggregate adhesion test device of the present embodiment is composed of a water spray pipe 1, a water pump 2, a nozzle 3, a thin line 4, a water tank 5, a sample cup 7, a barbed wire 8, a temperature-controlled electric furnace 10, and a base 11. , Asbestos net 12 connections form.

[0014] On the base 11, a water tank 5 is fixedly connected with a threaded fastening connector. The water tank 5 of the present embodiment is a plexiglass water tank, and the wall thickness of the water tank 5 is 10mm. It can simulate the situation that the road surface is soaked in water under the real rainfall conditions and is subjected to the vehicle load. The chemical composition of the rainwater 9 is different in different regions. The rainwater 9 in the water tank 5 of this embodiment adopts the rainwater 9 in Guangzhou. The PH value of Guangzhou Rainwater 9 is 4.9, and the conductivity is 15us·cm -1 , Fluoride ion 6umol / L, chloride ion 12...

Embodiment 2

[0018] In this embodiment, a barbed wire 8 is fixedly connected with a threaded fastening connector on the top of the water tank 5, and five sample cups 7 are fixedly installed on the barbed wire 8, and the shape of the sample cup 7 is a hemispherical crown body. Aggregate particles 6 coated with asphalt are fixed inside 7 . Five nozzles 3 are installed on the lower surface of each water spray pipe 1 through screw connection, and the nozzles 3 are connected with the interior of the water nozzle 1. The diameter of the spray holes of the nozzles 3 is 0.5mm, and the lower ends of the nozzles 3 are tied with thin wires. 4. The thin wire 4 is made of nylon wire, and the lower end of the thin wire 4 is bundled in the middle of the asphalt-coated aggregate particles 6 , and the asphalt-coated aggregate particles 6 are vertically placed in the sample cup 7 . Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0020] In this embodiment, a barbed wire 8 is fixedly connected with a threaded fastening connector on the top of the water tank 5, and five sample cups 7 are fixedly installed on the barbed wire 8, and the shape of the sample cup 7 is a hemispherical crown body. Aggregate particles 6 coated with asphalt are fixed inside 7 . Five nozzles 3 are installed on the lower surface of each water spray pipe 1 through screw connection, and the nozzles 3 communicate with the interior of the water nozzle 1. The aperture of the water spray hole of the nozzle 3 is 2mm, and the lower end of the nozzle 3 is tied with a thin line 4 , the thin wire 4 is made of nylon wire, the lower end of the thin wire 4 is bundled in the middle of the asphalt-coated aggregate particles 6 , and the asphalt-coated aggregate particles 6 are vertically placed in the sample cup 7 . Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com