Natural gas hydrate heat transfer performance testing apparatus used in X-ray CT equipment

A technology of heat transfer performance and testing device, which is applied in the field of petroleum scientific research instruments, can solve the problems such as the inability to meet the requirements of the size and quality of the stage, the combination of visual instruments and equipment, and the inability to study the heat transfer performance, etc., and achieve structural design. Compact and reasonable, comprehensive functions, the effect of meeting the parameter requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

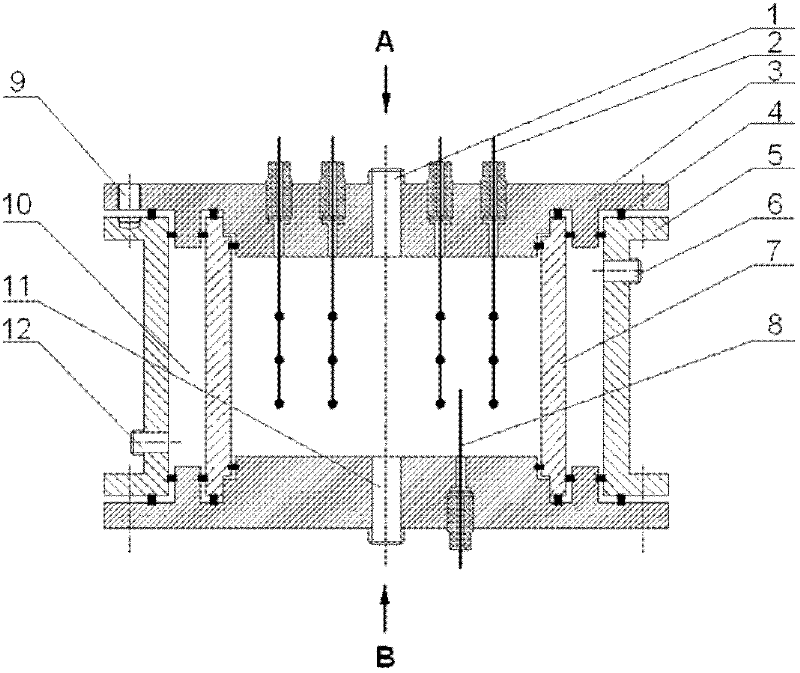

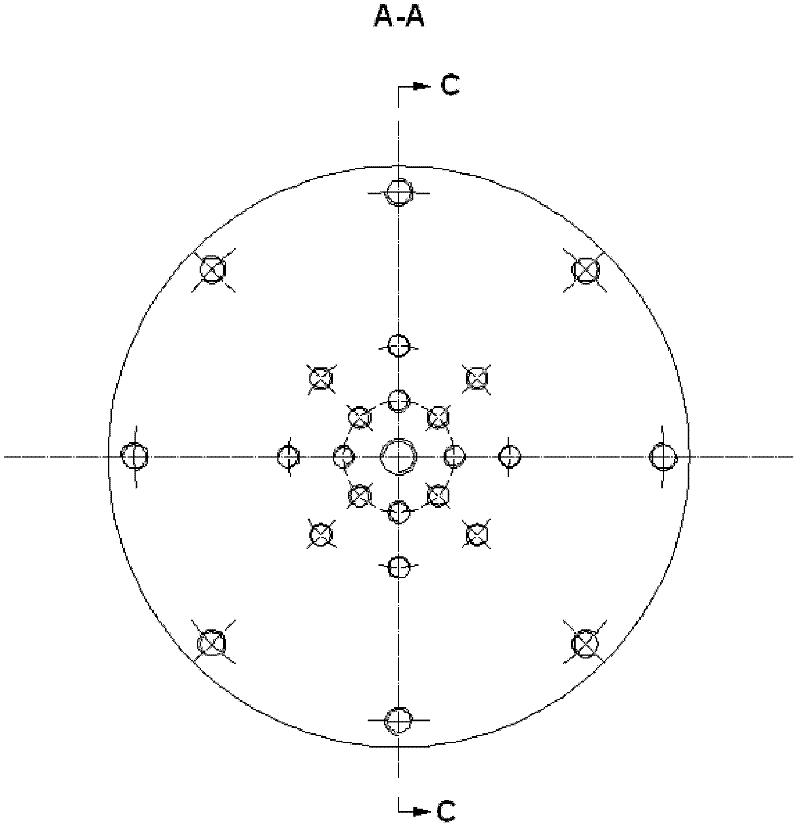

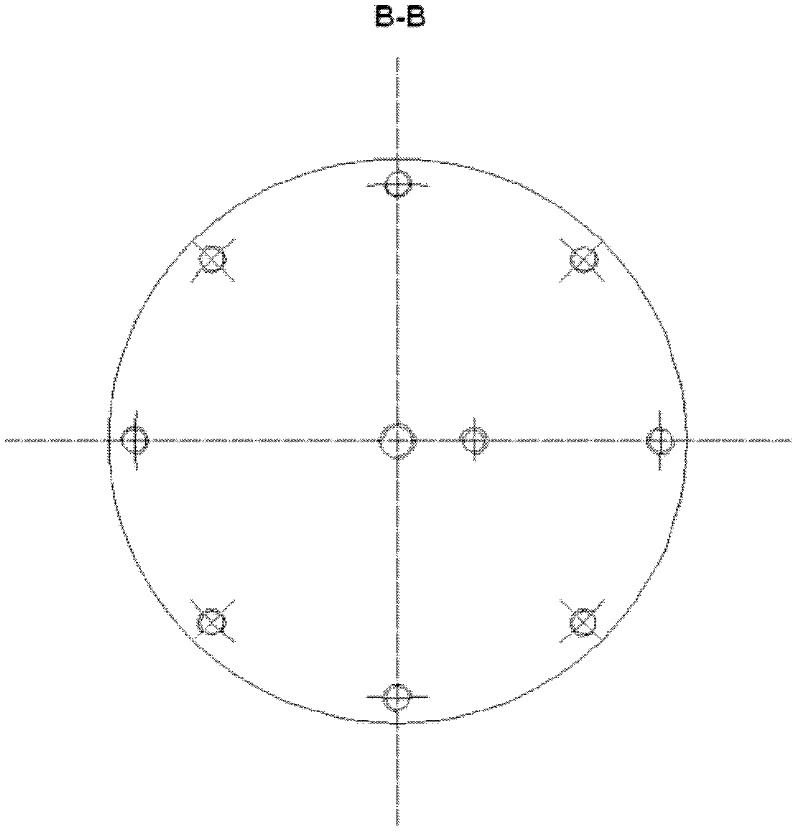

[0013] Figure 1-4 A device for testing the heat transfer performance of natural gas hydrate for X-ray CT equipment was demonstrated. The device is composed of two end covers and inner and outer sleeves. The end cover and the inner cylinder constitute a high-pressure reaction chamber, in which the formation and decomposition of natural gas hydrate can be simulated. A multi-point measuring thermistor is arranged in a double ring on the upper end cover for the study of heat transfer performance, and a pressure sensor is installed on the lower end cover to monitor the pressure of the reaction chamber. A hollow interlayer is formed between the end cover and the inner and outer cylinders, in which circulating coolant is introduced to control the temperature of the inner cylinder. The air inlet is used for high-pressure gas injection, and the air outlet is used for exhaust and pressure relief.

[0014] The steps to use the above heat transfer performance test device are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com