Inspection method of pipe seat fillet weld based on civa simulation software

A technology of simulation software and detection method, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problem of high experience dependence of engineering personnel, achieve the effect of small experience dependence, low detection efficiency, and not easy to miss detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

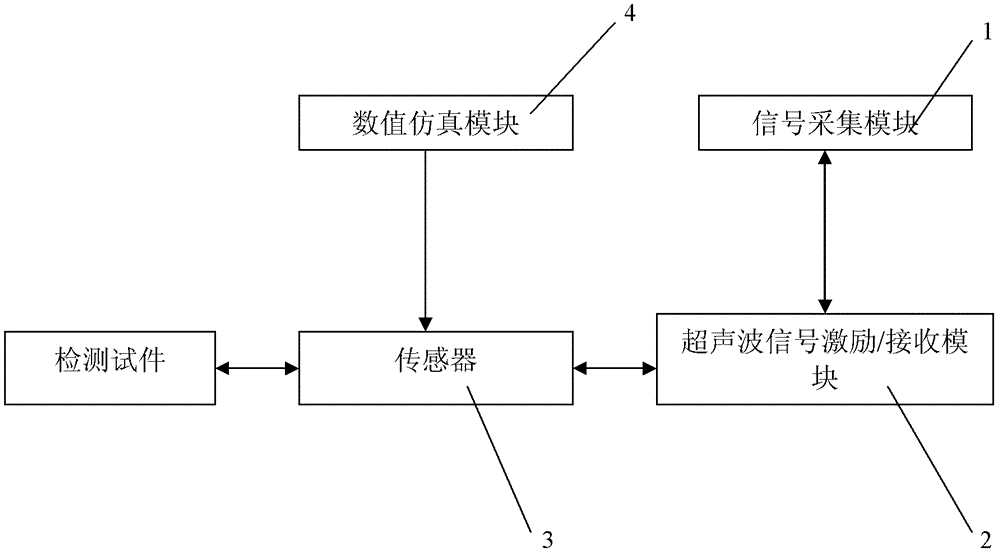

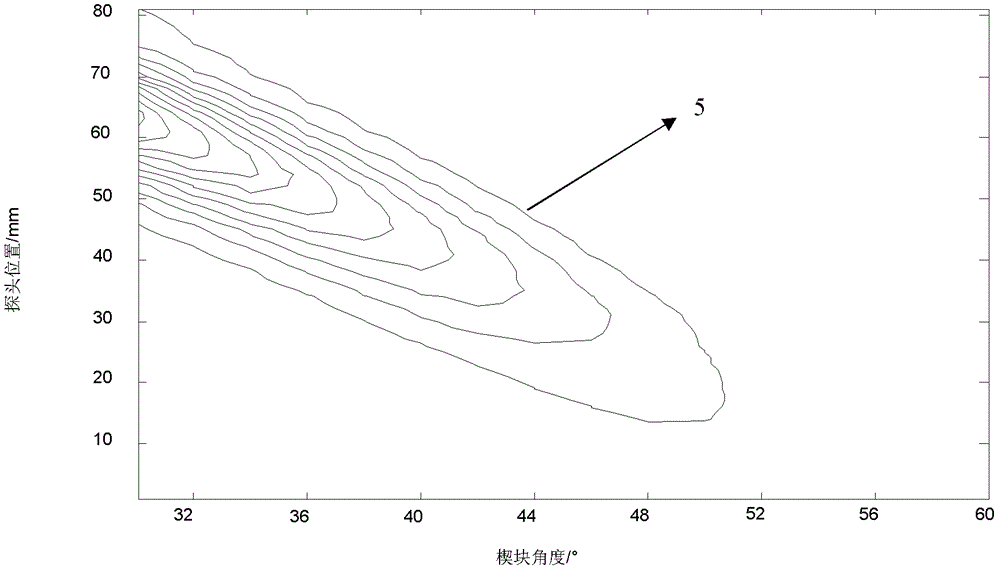

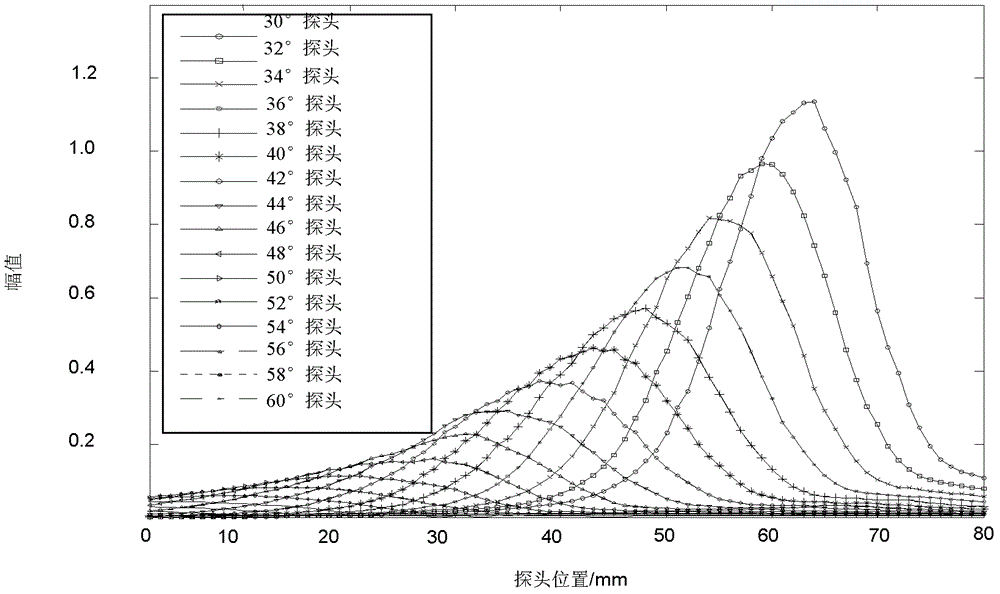

[0024] 1) In order to facilitate processing and testing, the test piece is welded by two steel plates with a thickness of 40mm. First, the numerical simulation module is used for simulation calculation, and the same simulation model as the actual test piece is established in CIVA software, and a hole-like defect with a length of 10 mm and a diameter of 2 mm perpendicular to the side surface is added to the model. Place the probe on the upper surface of the bottom plate for detection, the probe frequency is selected as 2.25MHz, the probe chip size is set as 10mm, only the angle of the probe is changed, and a simulation calculation is performed every two degrees from 30° to 60°. The sensor position-echo signal amplitude curves at different angles are obtained. The probe position-signal amplitude curve and the detectable area graph of the defect are obtained by summarizing and processing with MATLAB software.

[0025] 2) During the detection process, when the angle probe is sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com