Temperature controller test device and method for calibration test and aging test of temperature controller

A testing device and thermostat technology, applied in electrical testing/monitoring and other directions, can solve the problems of inconsistent spatial distribution of temperature field, inability to test thermostat aging, and inability to achieve rapid temperature rise and fall, and achieve uniform spatial distribution of temperature field, Compact structure, easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

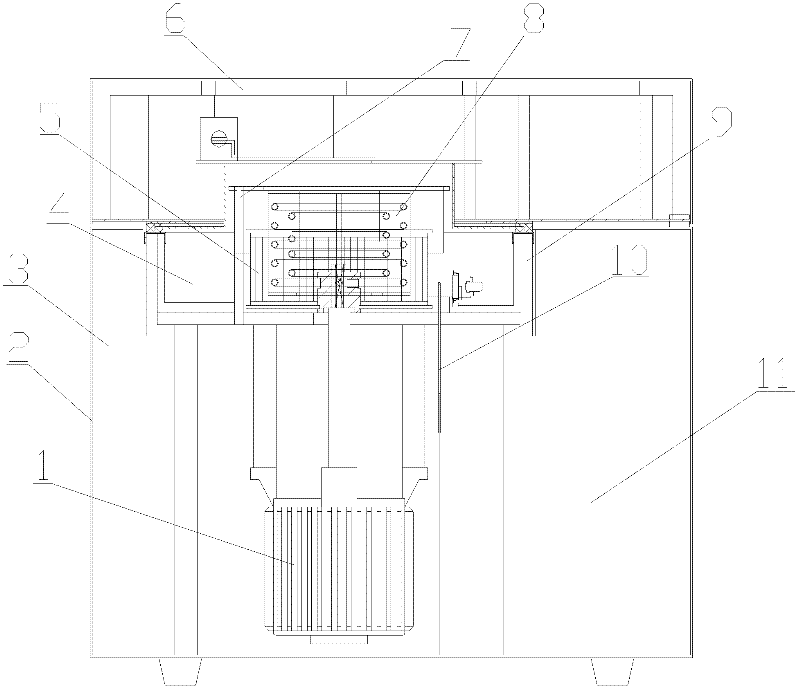

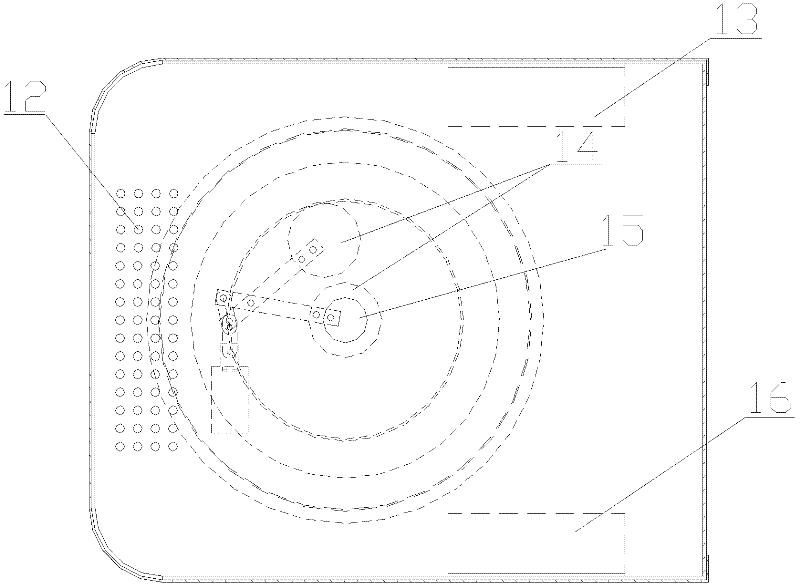

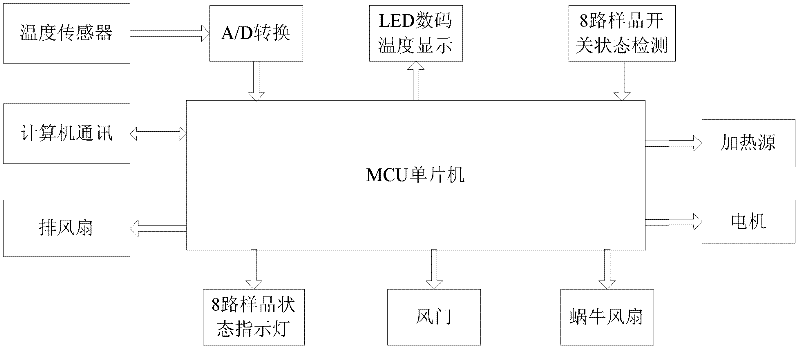

[0035] Such as figure 1 As shown, a thermostat testing device in this embodiment includes a casing box, an annular air bath constant temperature device arranged in the casing box, and a fast cooling upper cover with a damper arranged on the top of the annular air bath constant temperature device device, and a single-chip microcomputer control system, the annular air bath constant temperature device is a cylindrical annular cavity, arranged in the box, and each part is distributed around the center of the circle in an axisymmetric manner; the single-chip microcomputer control system is controlled under different working conditions The opening or closing of the damper.

[0036] The annular air bath constant temperature device is a cylindrical annular cavity, including an annular outer cavity 9 , an annular sample cavity 4 , a vortex fan 5 , a heating source 8 , a bracket 7 , a temperature sensor 10 and a motor 1 . The above-mentioned parts are distributed around the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com