Method for cultivating straw mushroom

A cultivation method and technology for straw mushrooms are applied in the fields of botanical equipment and methods, fertilizer mixtures, gardening, etc., and can solve problems such as liquid bacteria that are not involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

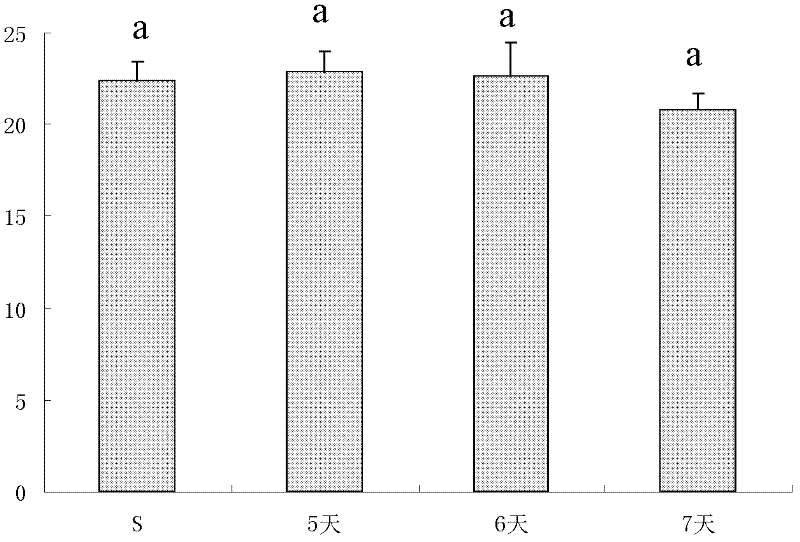

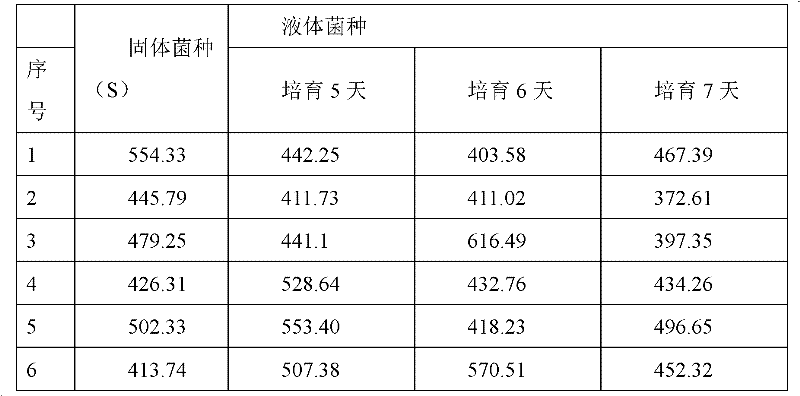

[0032] Embodiment 1: Cultivate straw mushrooms on the cultivation material with waste cotton as the main component by using the liquid strain of straw mushrooms (V23)

[0033] Experimental strain: straw mushroom (V23)

[0034] Experimental steps:

[0035] Cultivation raw material preparation: The cultivation raw material formula uses 75% waste cotton, 20% straw, and 5% quicklime. According to the amount of 2.1kg dry material per basket, the total amount of raw materials required is weighed in proportion. After the cultivation raw material formulations are mixed, add water to moisten , trampled, piled up, and used after one day of fermentation.

[0036] Cultivation raw materials are packed and sterilized: 45cm×55cm×13cm cultivation basket, the bottom of the basket is punched with small holes with a diameter of 5mm, the distance between the holes is 45mm, and the vertical and horizontal distances are the same; the four walls of the basket are punched with 5mm holes at 2cm from ...

Embodiment 2

[0041] Embodiment 2: Apply straw mushroom liquid strain (V5) to cultivate straw mushroom on the cultivation material with cottonseed husk as main component

[0042] Experimental strain: straw mushroom (V5)

[0043] Experimental steps:

[0044] Cultivation raw material preparation: the cultivation raw material formula adopts 70% cottonseed husk, 25% waste cotton, 5% quicklime, according to the consumption of 3.0kg dry material of each basket, takes the total amount of required raw material in proportion, after each formula of cultivation raw material is mixed, Add water to moisten, step on, pile up, and use after one day of fermentation.

[0045] Cultivation raw materials are packed and sterilized: 45cm×55cm×13cm cultivation basket, the bottom of the basket is punched with small holes with a diameter of 5mm, the distance between the holes is 45mm, and the vertical and horizontal distances are the same; the four walls of the basket are punched with 5mm holes at 2cm from the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com