Skull guiding formwork for calvarium reconstruction surgery and manufacturing method of skull guiding formwork

A technique of surgical operation and manufacturing method, applied in the direction of surgery, medical science, etc., can solve the problems of bone flap damage and unfavorable healing, and achieve the effect of reducing damage, facilitating recovery, and avoiding important anatomical structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The manufacturing method of the skull guide template used for skull top reconstruction surgery includes the following steps:

[0054] 1) Scan the patient's head with a three-dimensional CT scanning device or MRI device to obtain image data containing the patient's head information, filter out the skull data from the image data of the head information, and establish a three-dimensional contour model of the patient's skull;

[0055] 2) Compare the three-dimensional contour model of the patient's skull with the normal skull model, make the three-dimensional contour model of the patient's skull meet the appearance requirements of the normal skull through geometric transformation, and use the geometrically transformed three-dimensional model as the surgical target model;

[0056] 3) Determine the cutting route of the craniotomy, the number of bone flaps that need to be cut, and the shape of the bone flap. The cutting route avoids parts that do not need to be separated and important ...

Embodiment 2

[0075] The present invention will be specifically described in conjunction with cases of megacranial disease:

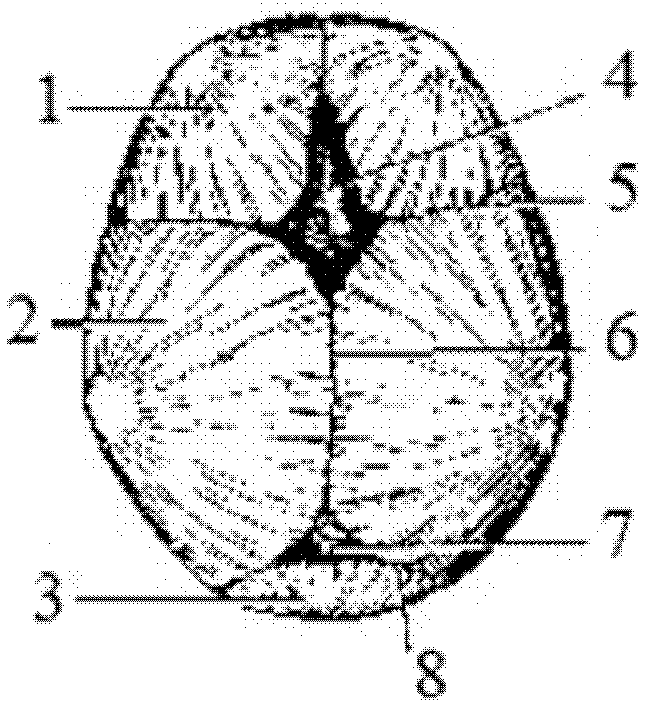

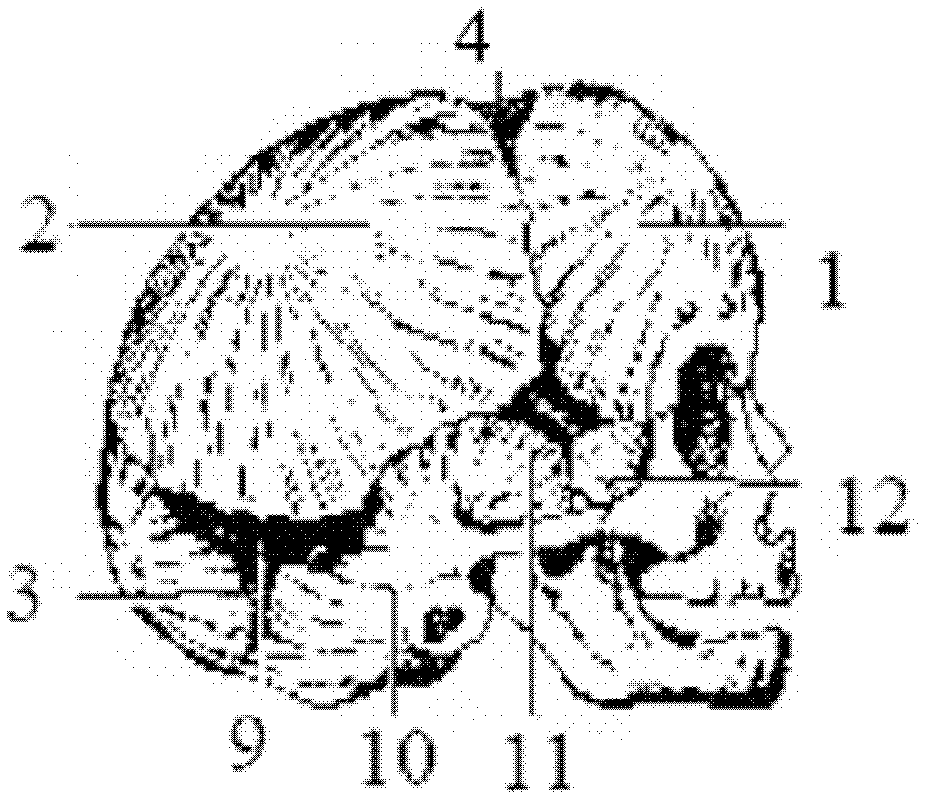

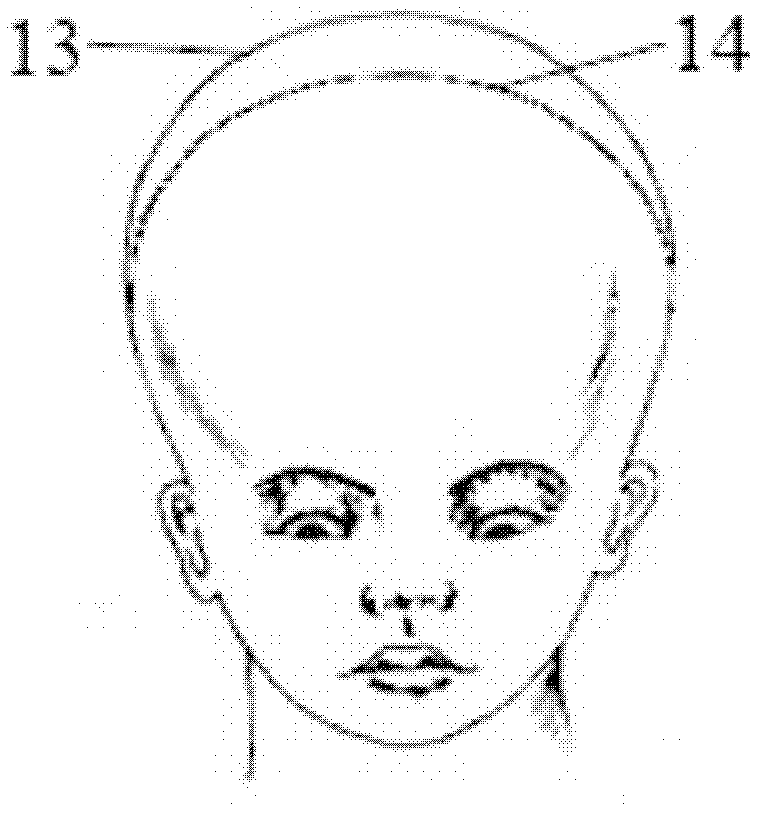

[0076] in Figure 1A with Figure 1B In the middle, the anatomical structure of the normal skull is shown. The frontal bone 1, the parietal bone 2 and the occipital bone 3 constitute the top of the skull. Figure 1C It shows the difference between the skull top of patients with megacephaly and normal people. Border 13 is the outline of the skull of patients with megacephaly, and border 14 is the outline of the skull of normal people. The purpose of reconstructive cranial cranioplasty surgery is to reduce the 13 craniopia contour to the 14 normal craniopia contour.

[0077] figure 2 The digital design method of cranial parietal reconstruction surgery and the design method process of cutting guide template stated in the present invention are described in detail.

[0078] According to the present invention, the patient needs to take CT or MRI to obtain such Figure 3A As shown...

Embodiment 3

[0086] Combining the cases of patients with oblique head, further illustrate the present invention:

[0087] Figure 14 describes the purpose of plastic surgery by adjusting the bone flap of the patient with oblique head. The morphology of the top 16 of the skull shown in 14A is not good, and the frontal bone 1 is not full. The CT data of the patient is reconstructed. Figure 14B What is shown is the shape obtained after simulating the postoperatively, which can be achieved by adjusting the position of the bone flap on the top of the skull. The original bone flap at the position of the bone flap 26 and the bone flap 27 can be interchanged and adjusted to Figure 14B The position shown, and the coronal suture 5 was reconstructed. The guide template is generated by extracting the outer surface of the bone flap 26 and the bone flap 27, and the guide template is processed by laser sintering technology, Figure 14C What is shown is that the doctor covers the guide template 26-g on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com