Method for recycling ethylene gas from tail gas and water alkaline washing tower thereof

A water washing and tail gas technology, applied in separation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of low ethylene content, affecting the quality of ethylene products, and high impurity content, and achieve easy operation, simple structure, and stable process parameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

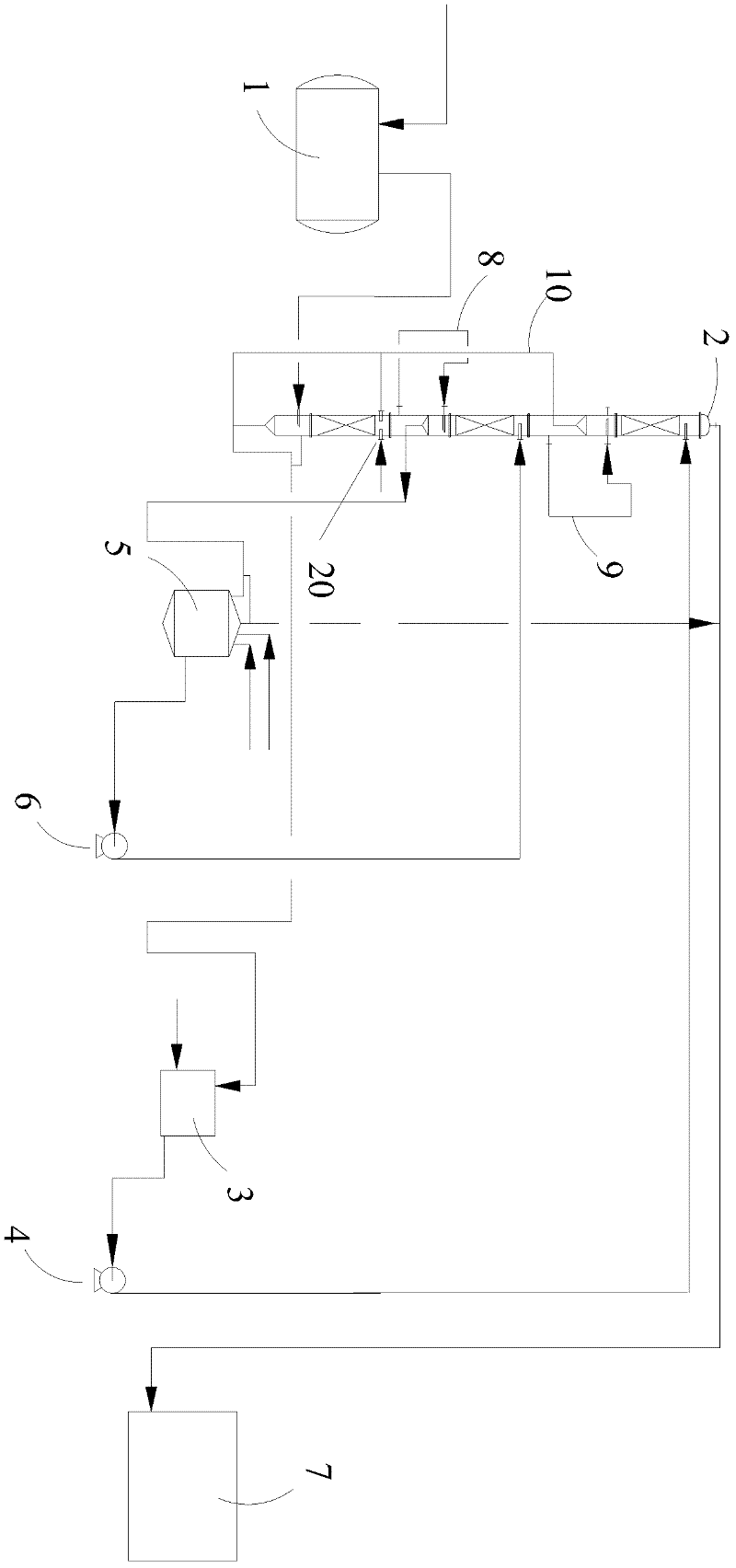

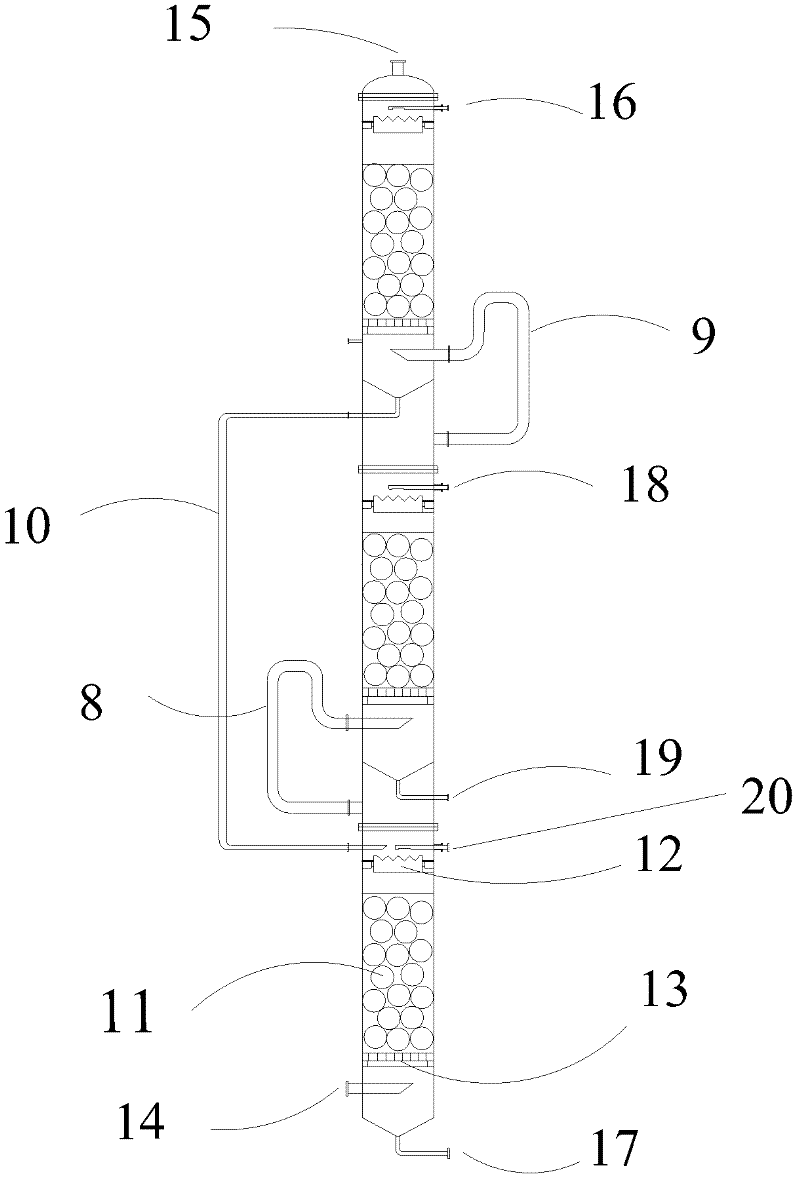

[0018] combine figure 1 , figure 2 , non-limiting examples are described as follows:

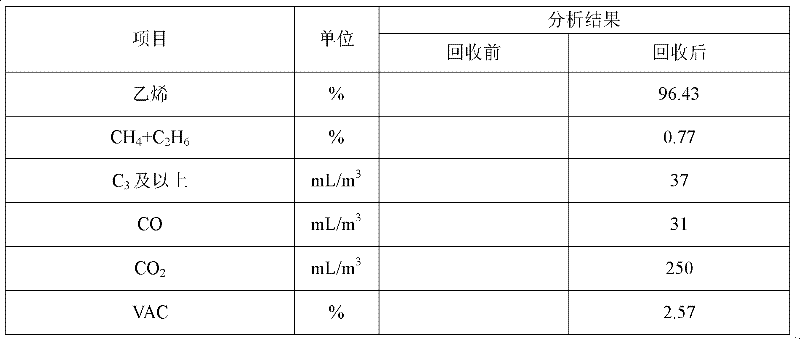

[0019] Start the water circulation pump 4 and the lye circulation pump 5 and maintain the negative pressure in the water-alkali washing tower 2, open the valve of the buffer tank 1, the tail gas enters the lower section from the gas inlet 14, and rises evenly under the action of the grid plate 13. The water sprayed down by the device 12 completes the first water washing in the ceramic ring 11 to remove the VAE emulsion and C in the tail gas. 3 and other impurities. The washed tail gas enters the middle section through the bypass air pipe 8, rises evenly under the action of the grid plate 13, and completes the second alkali washing in the ceramic ring 11 with the 2% lye sprayed down by the distributor 12 to remove A large amount of CO, CO in the exhaust gas 2 , aldehydes and VAC and other impurities. The tail gas after alkali washing enters the upper section through the bypass air pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com