Preparation method of polymer/titanium dioxide hybrid membrane with photocatalytic activity

A technology of photocatalytic activity and titanium dioxide, which is applied in the preparation of polymer/titanium dioxide hybrid film, polymer/titanium dioxide hybrid film products, and photodegradation of organic pollutants in water, which can solve the problem of weak loading force and reduced photocatalytic activity and other problems, to achieve the effect of good loading, high photocatalytic activity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

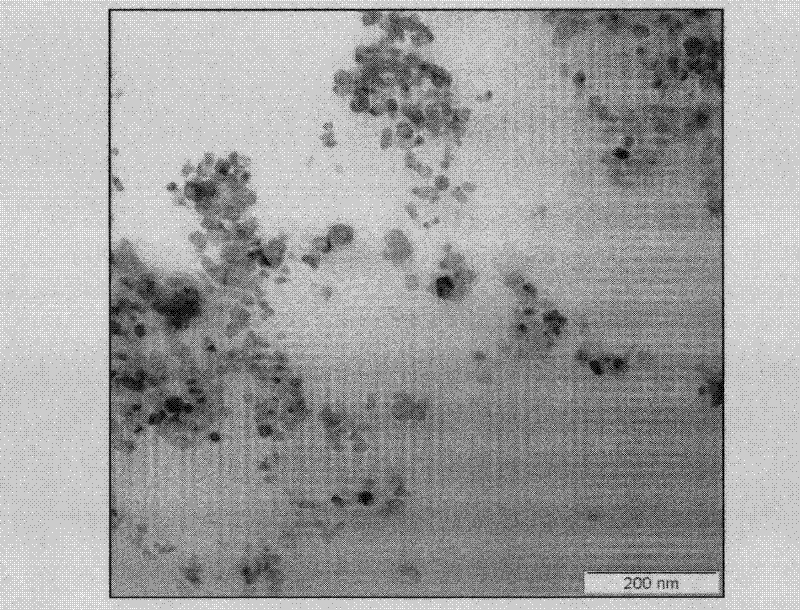

[0044] Preparation of polymer / titanium dioxide hybrid membrane: Add 0.5 g of titanium dioxide nanoparticles with a primary particle size of 20 nm produced by the gas-phase method into 45 mL of deionized water, ultrasonicate for 2 hours and mechanically stir for 1 hour to form a uniformly dispersed titanium dioxide dispersion . Add 5g of polyvinyl alcohol (PVA) into the three-necked flask containing the above-mentioned titanium dioxide dispersion, mechanically stir in an oil bath at 100°C for 1 hour to fully dissolve the PVA, then continue to stir in an oil bath at 60°C for 3 hours, Mix PVA and titanium dioxide nanoparticles evenly. Pour the mixed solution on the substrate, spread the film and control the thickness of the wet film to 1 mm, and naturally volatilize the deionized water to obtain the base film of the hybrid film with a thickness of about 0.06 mm.

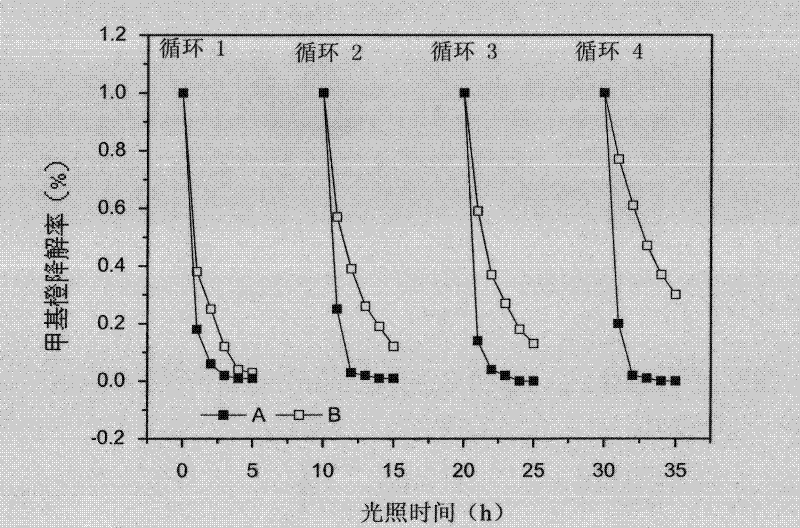

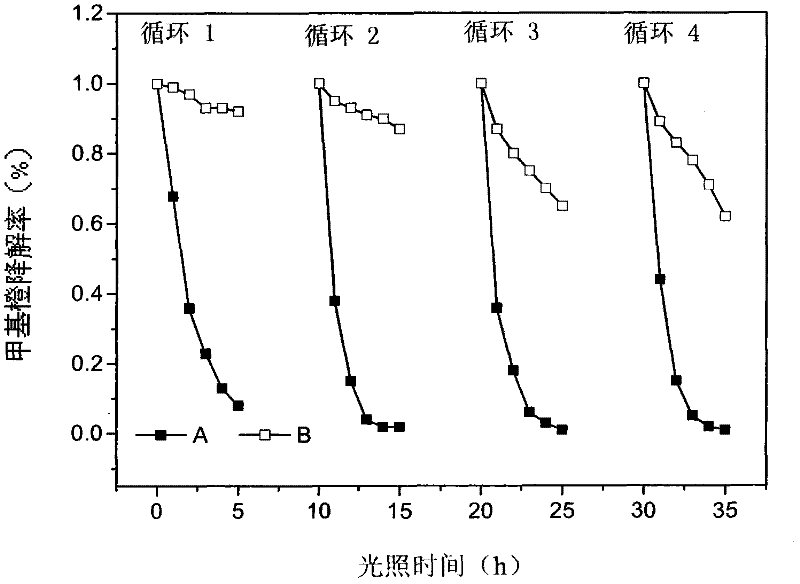

[0045] The base film of the obtained hybrid film is not subjected to any heat treatment, and the primary particle di...

Embodiment 2

[0048] Preparation of polymer / titanium dioxide hybrid membrane: Add 0.5 g of titanium dioxide nanoparticles with a primary particle size of 20 nm produced by the gas-phase method into 45 mL of deionized water, ultrasonicate for 2 hours and mechanically stir for 1 hour to form a uniformly dispersed titanium dioxide dispersion . Add 5g of polyvinyl alcohol (PVA) into the three-necked flask containing the above-mentioned titanium dioxide dispersion, mechanically stir in an oil bath at 100°C for 1 hour to fully dissolve the PVA, then continue to stir in an oil bath at 60°C for 3 hours, Mix PVA and titanium dioxide nanoparticles evenly. Pour the mixed solution on the substrate, spread the film and control the thickness of the wet film to 1 mm, and naturally volatilize the deionized water to obtain the base film of the hybrid film with a thickness of about 0.06 mm.

[0049] Put the base film of the above-mentioned hybrid film into a vacuum oven at 140°C, and heat-treat it in vacuum...

Embodiment 3

[0052] Preparation of polymer / titanium dioxide hybrid membrane: Add 0.5 g of titanium dioxide nanoparticles with a primary particle size of 20 nm produced by the gas-phase method into 45 mL of deionized water, ultrasonicate for 2 hours and mechanically stir for 1 hour to form a uniformly dispersed titanium dioxide dispersion . Add 5g of polyvinyl alcohol (PVA) into the three-necked flask containing the above-mentioned titanium dioxide dispersion, mechanically stir in an oil bath at 100°C for 1 hour to fully dissolve the PVA, then continue to stir in an oil bath at 60°C for 3 hours, Mix PVA and titanium dioxide nanoparticles evenly. Pour the mixed solution on the substrate, spread the film and control the thickness of the wet film to 1 mm, and naturally volatilize the deionized water to obtain the base film of the hybrid film with a thickness of about 0.06 mm.

[0053] Put the base film of the above hybrid film in a vacuum drying oven at 140°C and heat-treat it in vacuum for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com