Hydrothermal ageing device for multi-sample parallel catalyst

A hydrothermal aging and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as affecting repeatability, catalyst contamination, and inconsistent catalyst flow state, so as to ensure parallelism and repeatability, good repeatability and stability, saving steam generator effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

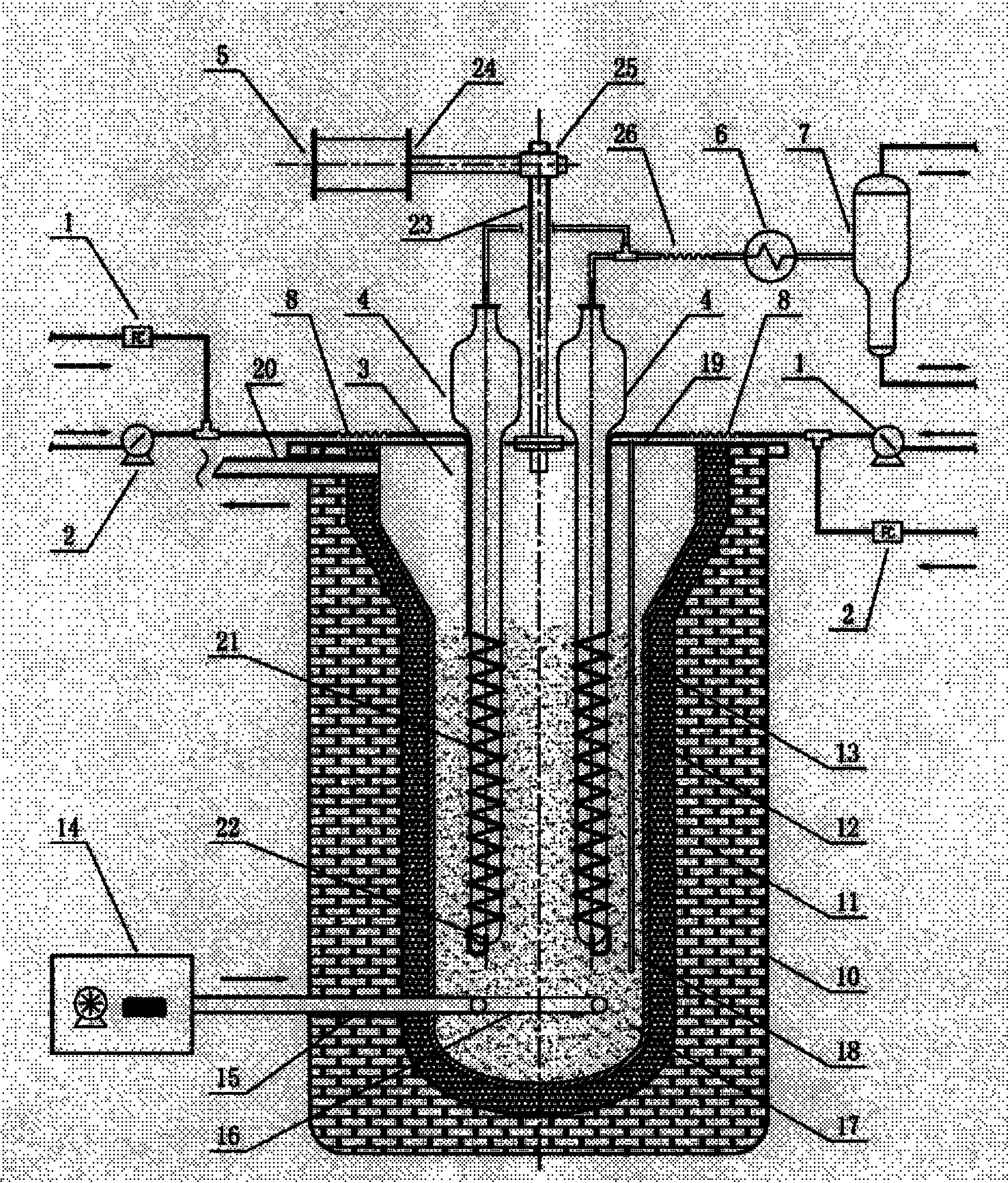

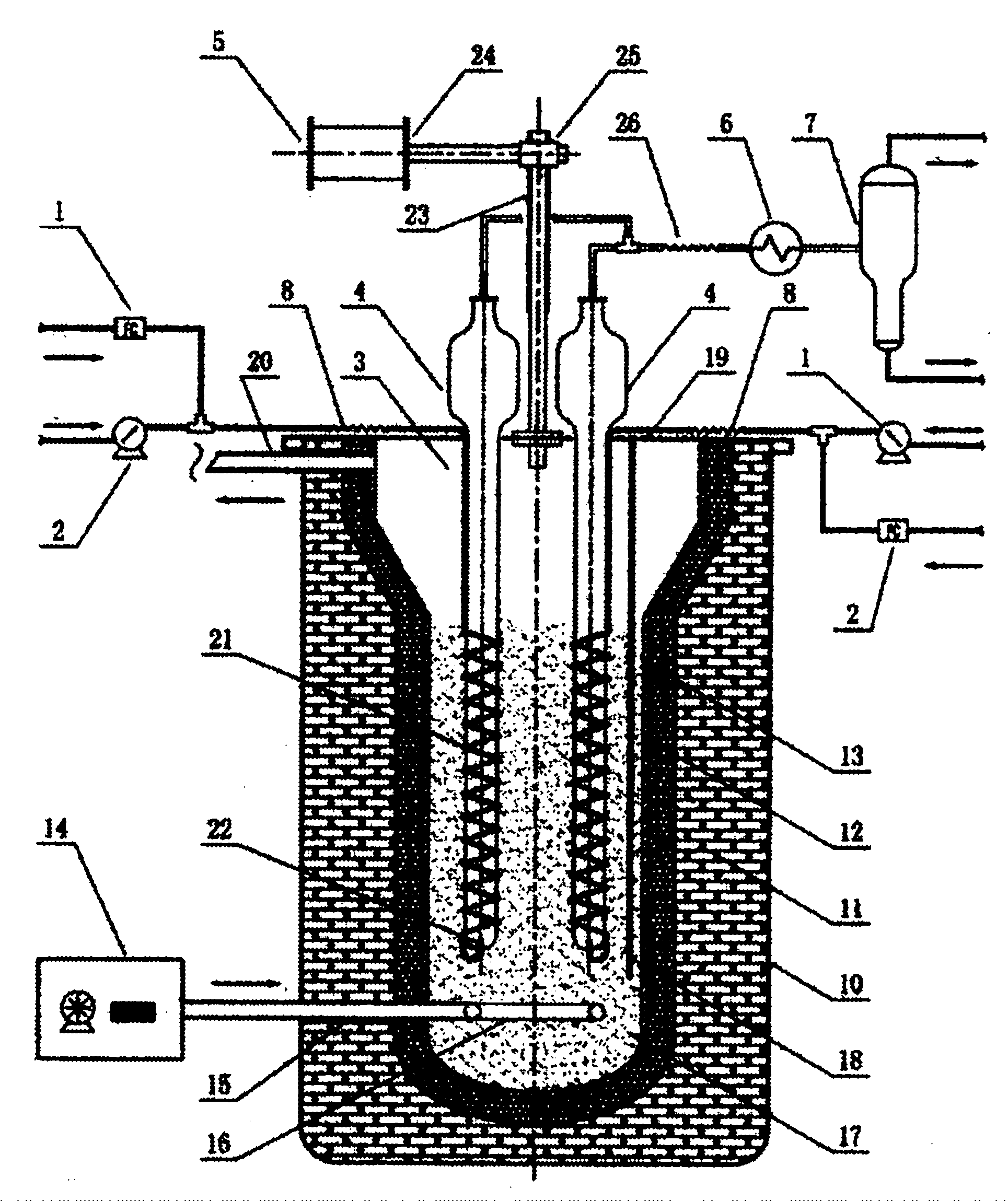

[0016] like figure 1 As shown, the key components of a multi-sample parallel catalyst hydrothermal aging device provided by the present invention include: water feed pump 1, gas flow controller 2, sand bath heating system 3, hydrothermal aging reactor 4, reactor lifting Mechanism 5, tail gas cooler 6 and gas-liquid separation tank 7.

[0017] The circumference of the hydrothermal aging reactor 4 is evenly arranged in the sand bath furnace of the sand bath heating system 3, the settling section of the hydrothermal aging reactor 4 is exposed to the sand bath furnace, and its fluidized section is immersed in the quartz sand 17 of the sand bath furnace, Each hydrothermal aging reactor 4 is transported fluidized medium and gas by independent water feed pump 1 and gas flow controller 2 respectively, and all hydrothermal aging reactors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com