Tape threading device for horizontal drying furnace

A drying furnace and belt threading technology, which can be applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of affecting the operation rate of the drying furnace and the time-consuming operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description is merely exemplary in nature and not intended to limit the disclosure, application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

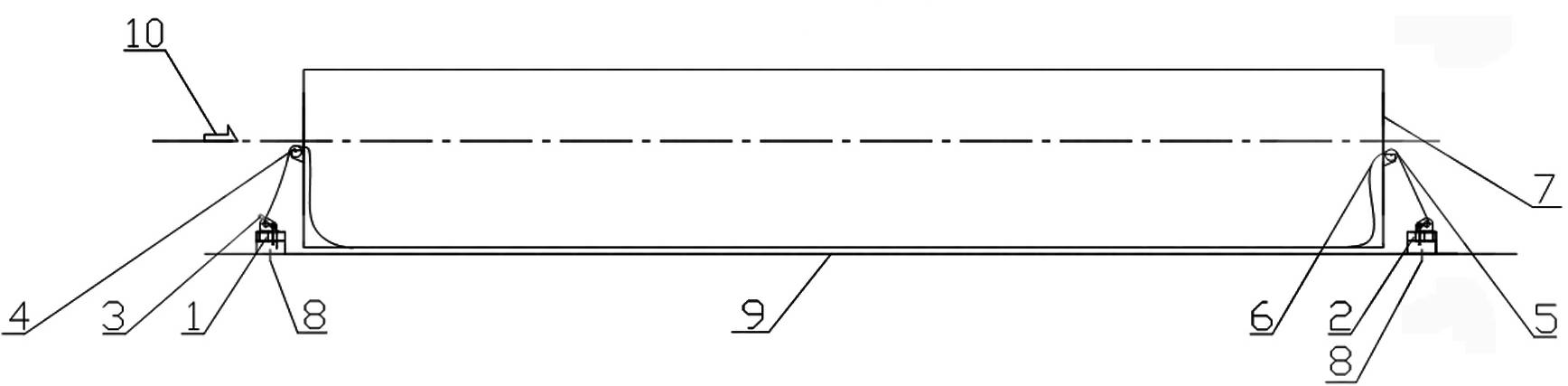

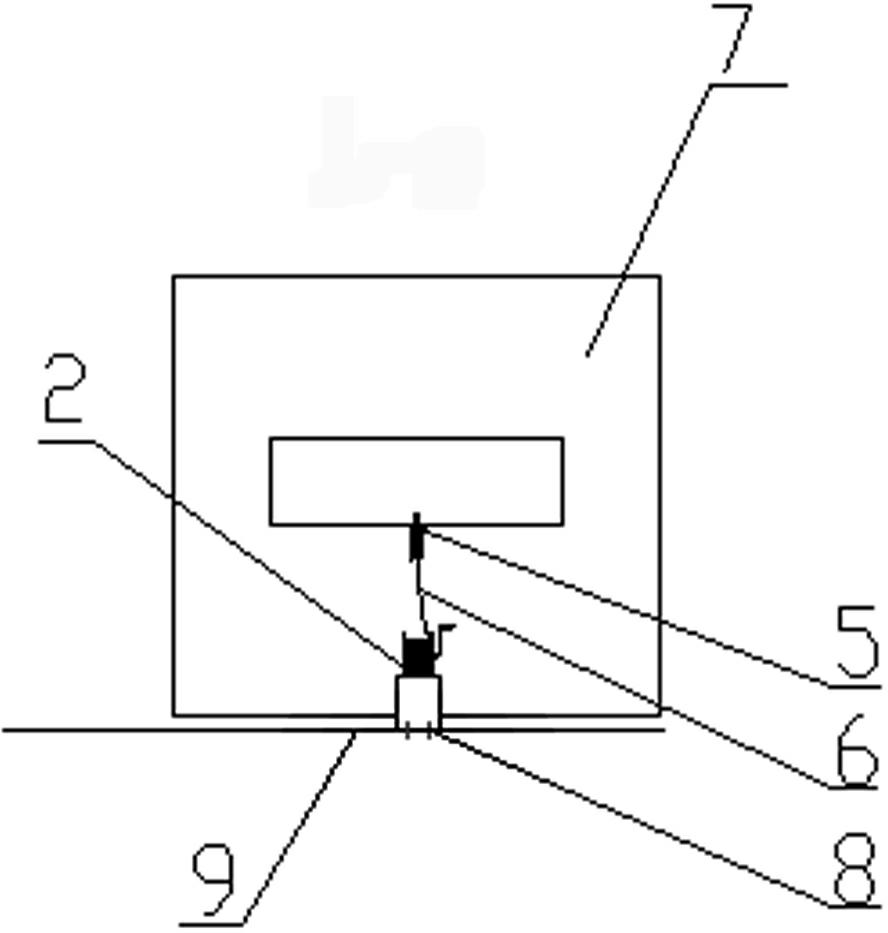

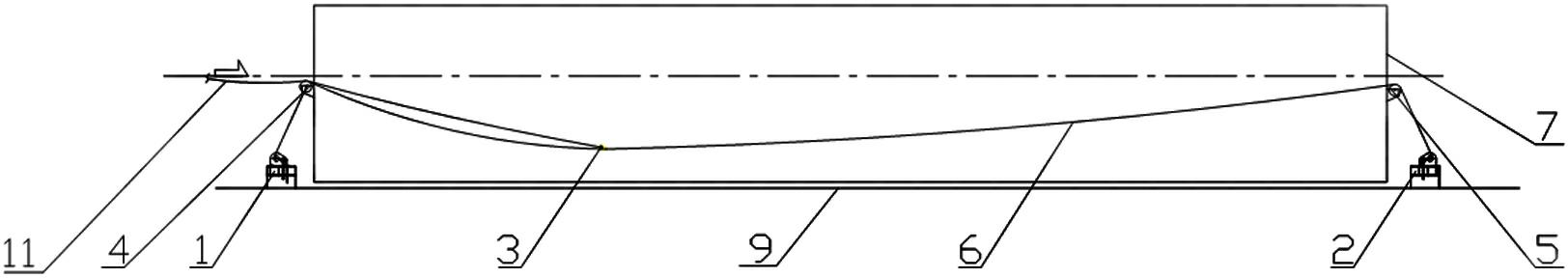

[0020] preferred reference figure 1 , figure 1 It is the front view of the belt threading device of the horizontal drying furnace in the initial state according to the present invention. Such as figure 1 As shown, the horizontal drying furnace belt threading device includes an entrance winch 1, an exit winch 2, a hook 3, an entrance pulley 4, an exit pulley 5, a steel wire rope 6, a drying furnace 7, and a fixing bolt 8. The entrance winch 1 and the exit winch 2 can be both automatic or manual, or one is automatic and the other is manual. Entrance winch 1 and exit winch 2 are equipped with self-locking function, which can be locked as needed when the strip steel is threaded to prevent further movement of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com