Autoclave molding method and autoclave molding apparatus

A molding method and molding device technology, applied in the direction of pressure vessels used in chemical processes, can solve problems such as difficulties, achieve the effects of reducing equipment costs, preventing uneven preparation, and reducing curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

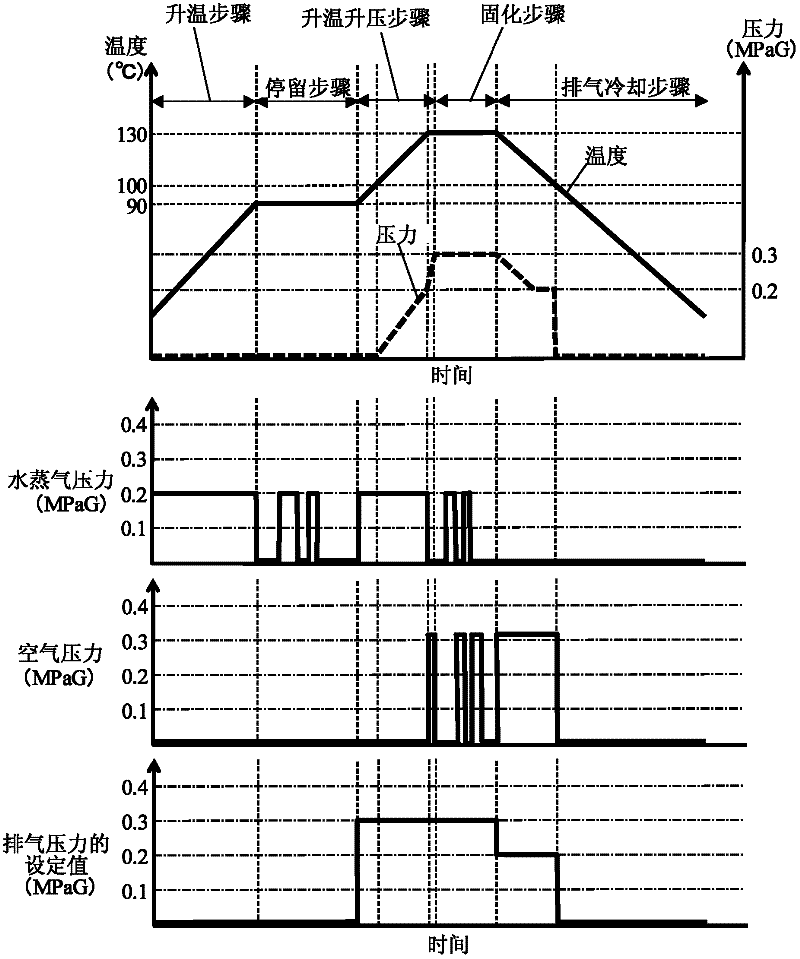

[0066] Preferred embodiments of the autoclave forming method and the apparatus used for the method of the present invention will be described in detail below based on the accompanying drawings. In the first embodiment, a thermosetting resin is used as the matrix.

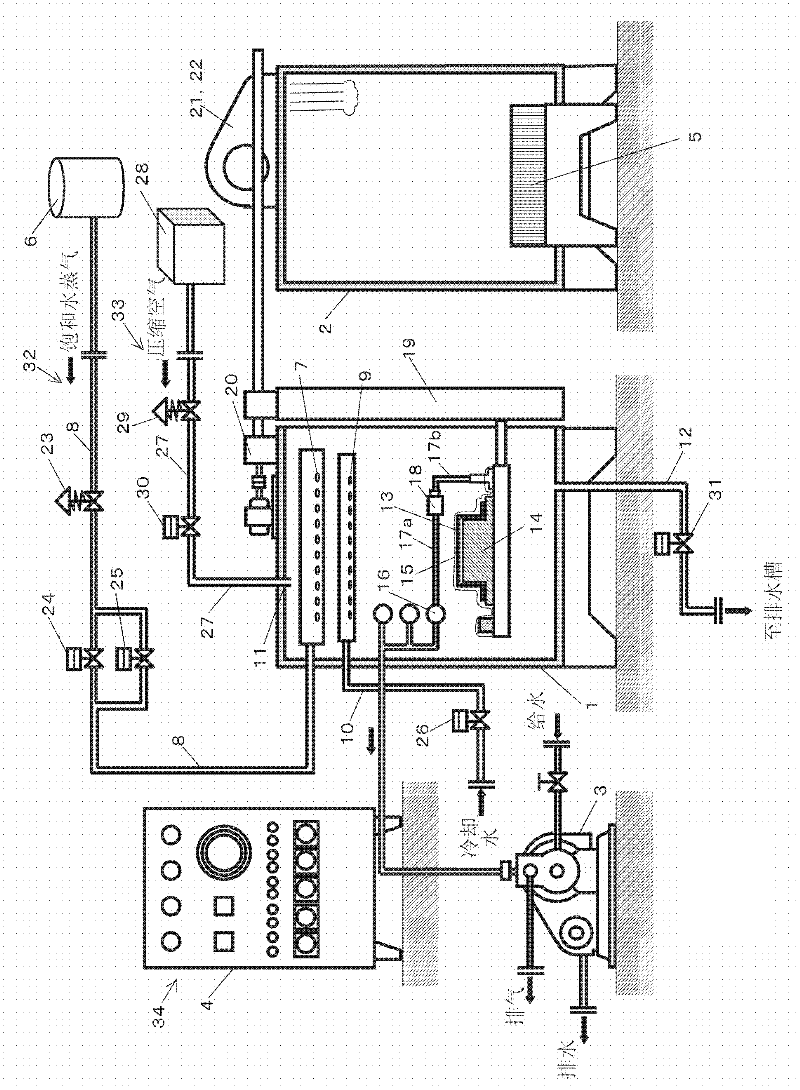

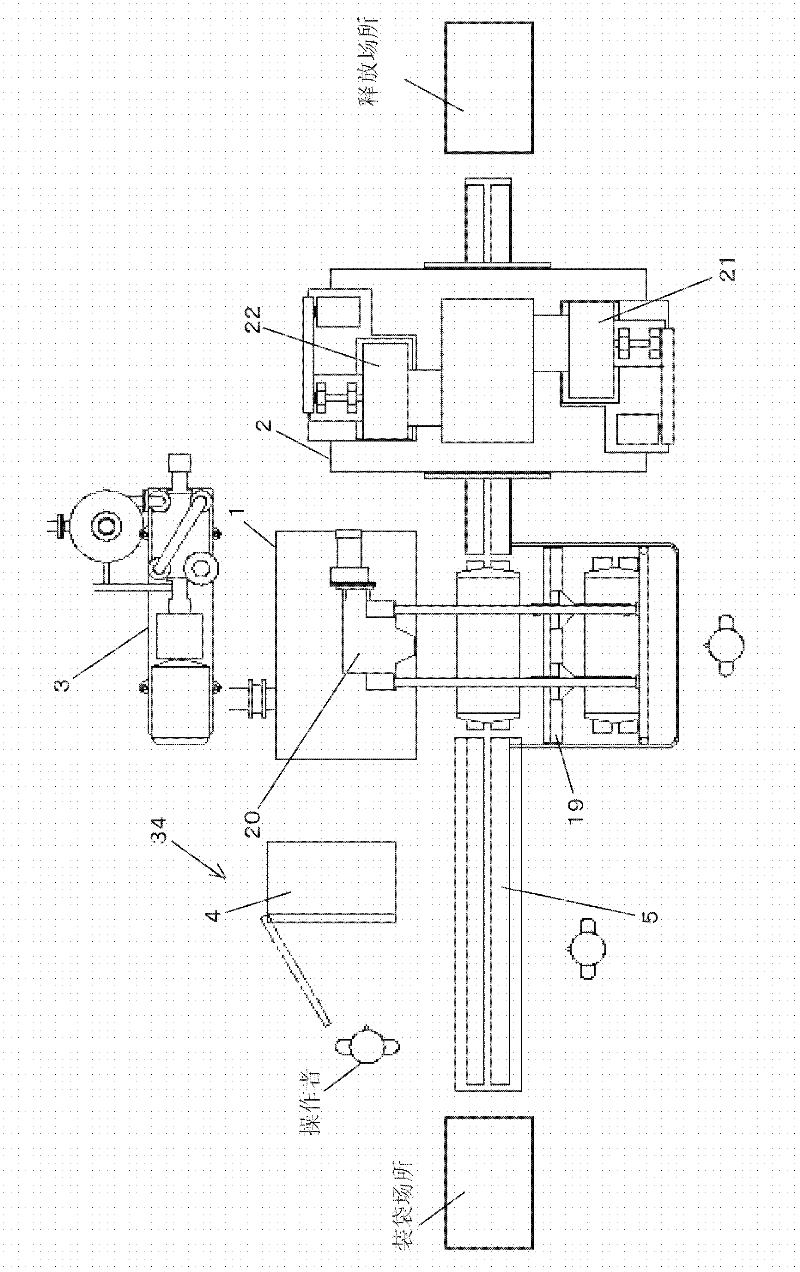

[0067] exist figure 1 with 2 A schematic structure is shown in to show the whole autoclave apparatus of the present invention.

[0068] The device mainly includes a molding chamber 1, a drying chamber 2, a water-sealed vacuum pump 3, a control panel 4, an automatic conveying line 5, that is, a conveyor, a boiler 6, pipelines connected thereto, and a plurality of valves. The detailed structures of these are described below.

[0069] That is, the autoclave molding apparatus forms the composite material 13 by placing it in the vacuum bag 15, then placing it in the molding chamber 1, and heating and pressurizing it. The composite material 13 is obtained by impregnating a fibrous substrate (which in this embodiment ...

example 1

[0109] The above-mentioned Embodiment 1 is partially modified into the form of another embodiment of the present invention (described below).

[0110] Image 6 A schematic diagram of the air nozzle showing another form of the main part of the autoclave apparatus of the present invention is shown. A plurality of nozzles 7 for supplying saturated water vapor into the molding chamber 1 also serve as nozzles 11 for supplying compressed air, which are arranged at the upper portion of the molding chamber 1 in the above-described embodiment. Therefore, compressed air is showered onto the vacuum bag 15 in a similar manner to saturated water vapor showered onto the vacuum bag 15, and local pressure variations to the composite material 13, ie, the product to be molded, are reduced. Therefore, a stable molded product without process variation can be manufactured.

[0111] in which the number of the member is not stated Image 6 , refer to the description of Embodiment 1 above.

example 2

[0113] Fast curing prepregs can be formed by the method and apparatus of the present invention. The fast-curing prepreg as the composite material 13 contains a thermosetting resin as a matrix that reacts and cures in a short time. The fast curing prepreg may be, for example, Tough-Qure (trade name) manufactured by Mitsubishi Rayon Co., Ltd. In this case, the reaction curing time at 130°C is 30 minutes, whereas in the case of a general prepreg, it is 1 hour at 130°C. In addition, because the saturated water vapor used here has a large amount of heat, the temperature variation is reduced, the curing time is significantly shortened, and the productivity is significantly improved. The shorter the curing time, the less heat energy is discarded, thus saving energy. The advantage of fast cure can be maximized by the reduction of temperature variation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com