Laminated neutron radiation shielding composite material and preparation method thereof

A technology of radiation shielding and composite materials, which is applied in the field of preparation of laminated neutron shielding radiation materials, and can solve problems such as unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

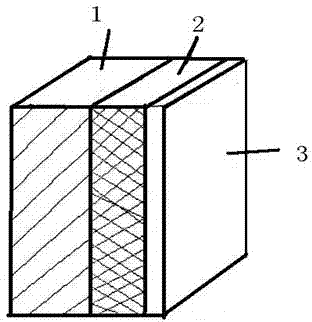

[0044] Add 12 parts of imidazole curing agent methylimidazole and 3 parts of silane coupling agent KH-550 to 100 parts of bisphenol A-epoxy resin, stir well to make it uniform, and divide it into three parts; Parts resin mass 5% B 4 C powder and this part of resin quality 10% PbO powder, then fully stir to make it uniform. Lay polyethylene fiber cloth in the mold, use a brush to dip the prepared epoxy resin without any powder and brush it on the polyethylene fiber cloth to make it soak in the polyethylene fiber cloth, and then lay new polythene on it. Repeat the above steps for the vinyl fiber cloth to make it thick to 5 cm. As a neutron moderator, continue laying the boron fiber cloth on it, dip it with a brush and add B 4 Brush the epoxy resin of C powder onto the boron fiber cloth, make it soak into the boron fiber cloth, continue laying the new boron fiber cloth on it, repeat the above steps, make the thickness reach 2 cm, and continue laying the grafted lead acrylate. P...

Embodiment 2

[0049] Add 8 parts of imidazole curing agent ethylimidazole and 3 parts of silane coupling agent KH-550 to 100 parts of bisphenol A-epoxy resin, stir well to make it even, and divide it into three parts; Parts resin mass 15% B 4 C powder and the PbO powder with 20% of the mass of the resin are fully stirred to make them uniform. Lay polyethylene fiber cloth in the mold, use a brush to dip the prepared epoxy resin without any powder and brush it on the polyethylene fiber cloth to make it soak into the polyethylene fiber cloth, and then lay new polythene on it. Repeat the above steps for the vinyl fiber cloth to make it thick to 5 cm. As a neutron moderator, continue laying the boron fiber cloth on it, dip it with a brush and add B 4 Brush the epoxy resin of C powder onto the boron fiber cloth, make it soak into the boron fiber cloth, continue laying the new boron fiber cloth on it, repeat the above steps, make it thick to 2 cm, and continue laying the grafted lead acrylate. P...

Embodiment 3

[0051] Add 15 parts of imidazole curing agent methylimidazole and 7 parts of silane coupling agent to 100 parts of bisphenol A-epoxy resin, stir well to make it uniform, and divide it into three parts; 20% of B 4 C powder and the PbO powder of 30% of the mass of the resin are fully stirred to make them uniform. Lay polyethylene fiber cloth in the mold, use a brush to dip the prepared epoxy resin without any powder and brush it on the polyethylene fiber cloth to make it soak into the polyethylene fiber cloth, and then lay new polythene on it. Repeat the above steps for the vinyl fiber cloth to make it thick to 5 cm. As a neutron moderator, continue laying the boron fiber cloth on it, dip it with a brush and add B 4 Brush the epoxy resin of C powder onto the boron fiber cloth, make it soak into the boron fiber cloth, continue laying the new boron fiber cloth on it, repeat the above steps, make it thick to 2 cm, and continue laying the grafted lead acrylate. Polyethylene fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com