Two-sided automatic-alignment intermittent thin film coating method

An automatic alignment, intermittent technology, applied in chemical instruments and methods, lamination devices, control lamination, etc., can solve the difficulty of increasing alignment, unfavorable practical applications, positioning sensor accuracy, real-time, synchronization And the problem of very high error requirements, to achieve simple and convenient processing technology, simple process, and achieve the effect of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

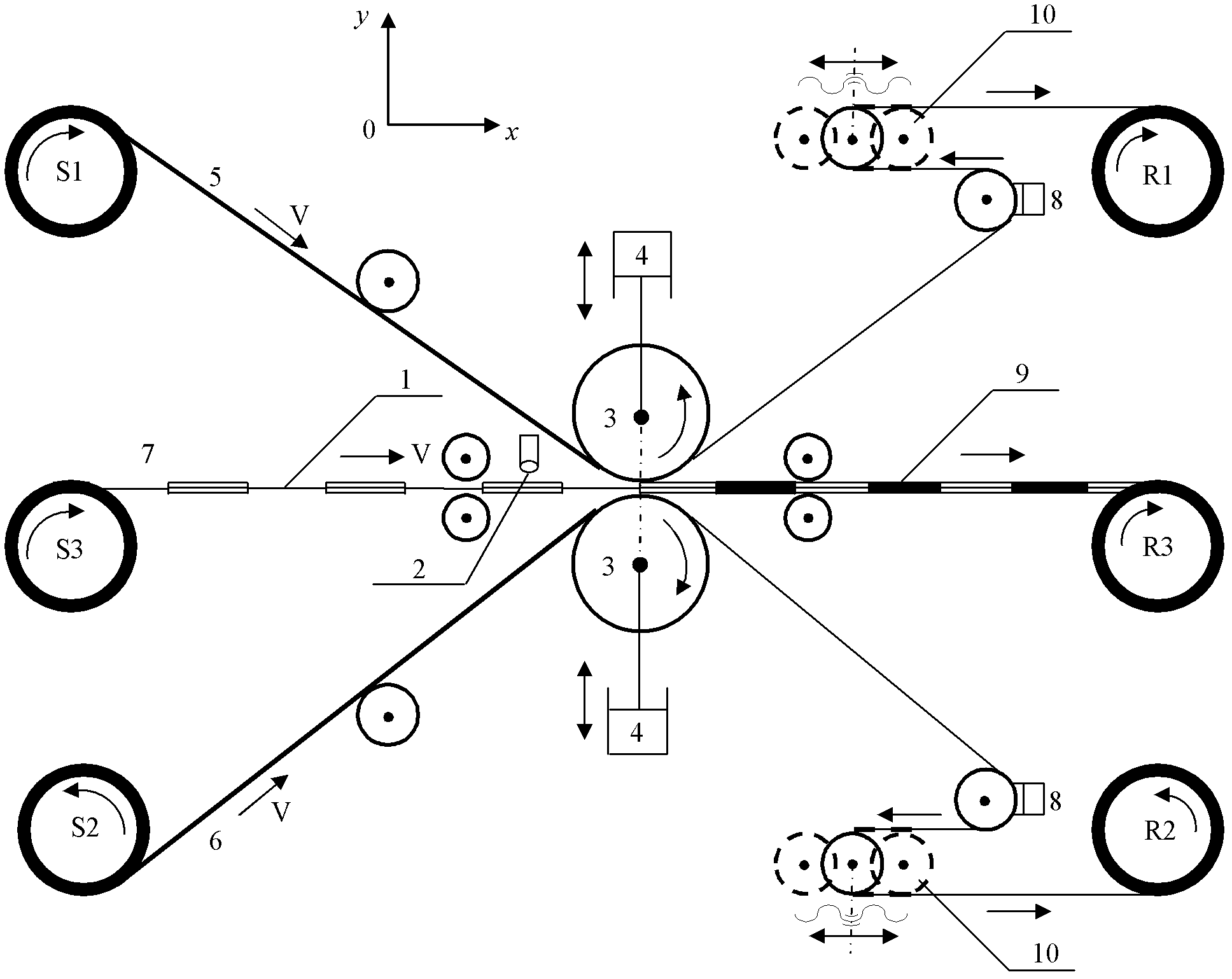

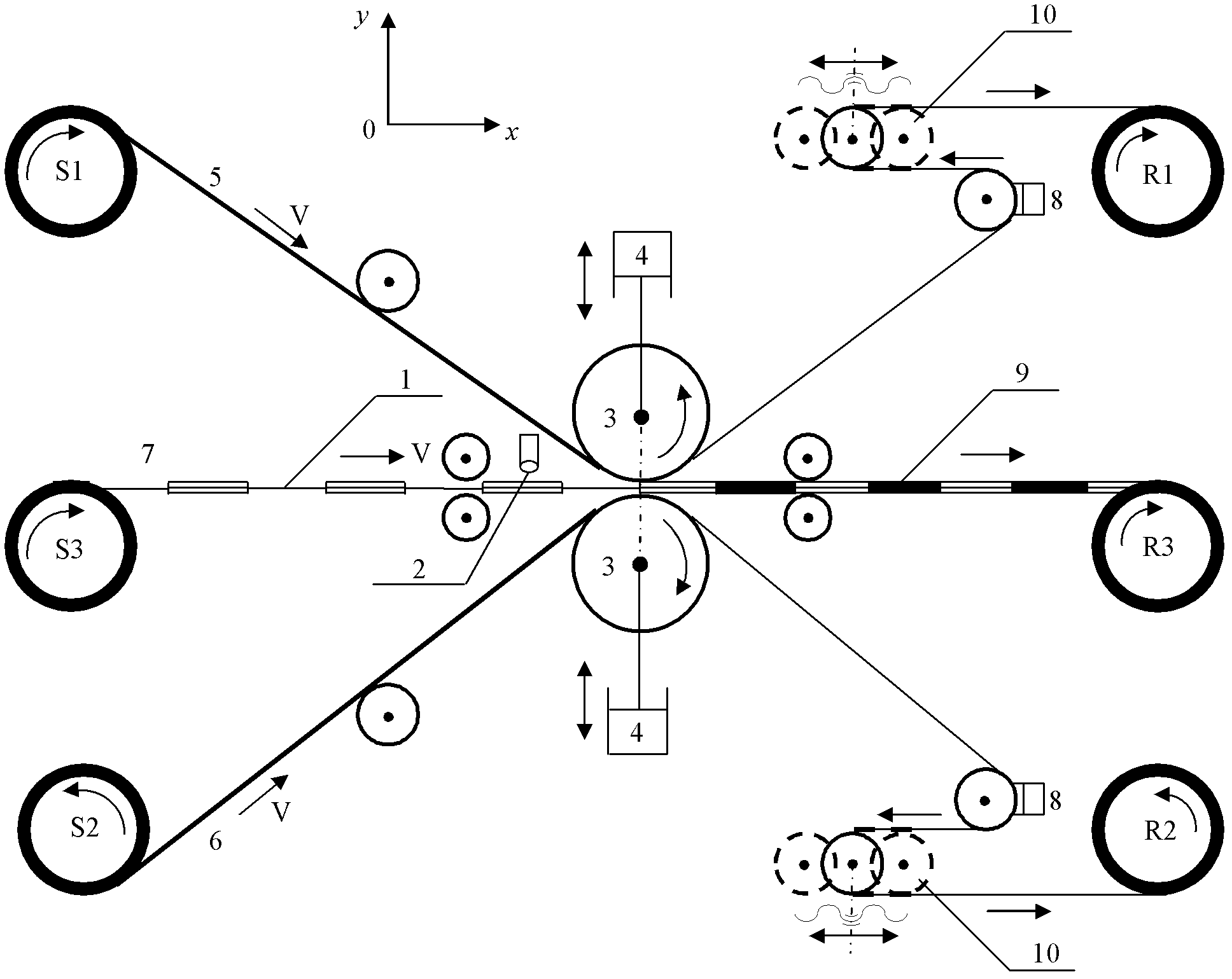

Embodiment Construction

[0026] The film double-sided automatic alignment intermittent coating method provided by the present invention is to intermittently coat two layers of film coating materials on the membrane assembly to be coated. The specific method is: distribute the membrane assembly to be coated with the coating window In the middle position, one coating film assembly is arranged above and below the film assembly to be coated. These three types of films are respectively moved by three sets of rollers with transmission function under the drive of the servo motor. Line speeds are equal. Use a color mark positioning sensor to detect the coating windows located on the film assembly to be coated. These windows have the same shape, that is, the length and width are equal, and the windows are intermittent, and any adjacent two windows The distance between them is also equal. When the color mark positioning sensor detects the right edge of a certain window, the upper and lower transfer pressure ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com