Label implanting type multifunctional rotary die-cutting machine

A round-pressing and multi-functional technology, which is applied in the field of label-implanted multi-functional round-pressing die-cutting machines, can solve problems such as insufficient functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

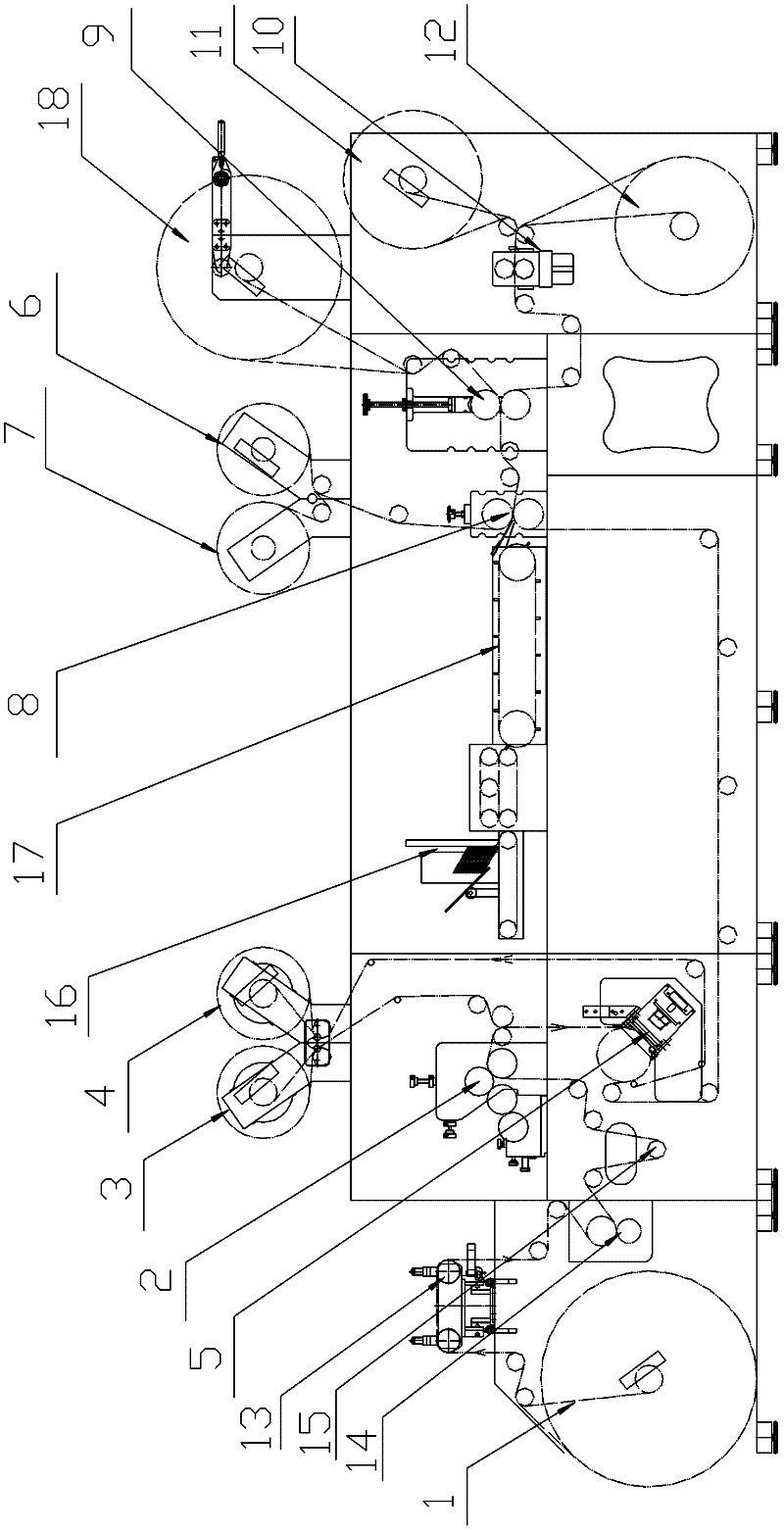

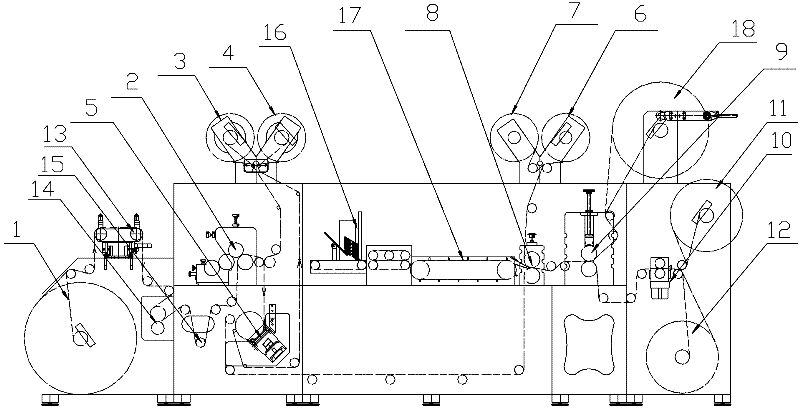

[0015] With reference to the accompanying drawings, a label-implanted multifunctional rotary die-cutting machine includes an unwinding unit 1, a flexo printing unit 2, a cold stamping device, a UV drying device 5, a laminating device, a booklet label implanting compound unit 8, Rotary die-cutting unit 9, slitting unit 10 and winding unit. On the travel route of the paper, the unwinding unit is connected with the flexo printing unit, the flexo printing unit is connected with the UV drying device, the UV drying device is connected with the cold ironing device, and the UV drying device is connected with the booklet label implanting compound unit at the same time. On the travel route of the lamination, the lamination device and the booklet label implant compound unit are connected. On the travel route of the paper (lamination, implanted label), the booklet label implant compound unit is connected with the rotary die-cutting unit, the rotary die-cutting unit is connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com