TPU film with excellent surface polarity and preparation process thereof

A preparation process and surface polarity technology, applied in the field of TPU film and its preparation process, can solve the problems of unfavorable ink printing, unfavorable gluing, small surface tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

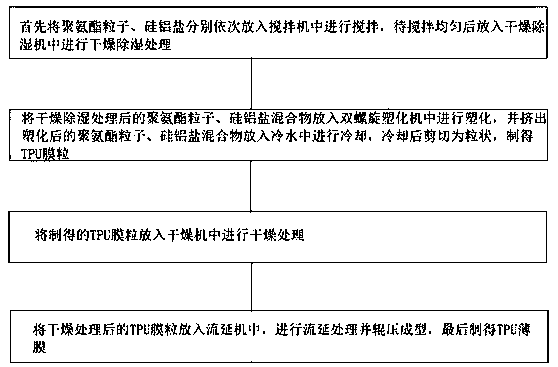

[0018] as attached figure 1 As shown, a TPU film with good surface polarity and its preparation process, the weight composition of the TPU film is 80-95 parts of polyurethane particles, 5-15 parts of silicon aluminum salt, and the preparation process steps of the TPU film are as follows: :

[0019] (1) First, put 80-95 parts of polyurethane particles and 5-15 parts of silicon-aluminum salt into the mixer in turn for stirring. After stirring evenly, put them into a drying dehumidifier for drying and dehumidification treatment for 2-3 hours and take them out;

[0020] (2) Put the polyurethane particles and silicon-aluminum salt mixture after drying and dehumidification into the twin-screw plasticizer, plasticize under the condition of the screw temperature of the twin-screw plasticizer at 200-210°C, and extrude the plastic The melted polyurethane particles and the silicon-aluminum salt mixture are put into cold water for cooling, and after cooling, they are sheared into granule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com