Device and method for preparing array patterns based on static spray printing

A pattern and inkjet printing technology, applied in printing, typewriters, etc., can solve the problems of poor controllability of continuous inkjet printing, low positioning accuracy of inkjet printing and printing resolution, and difficulty in improving printing resolution, achieving rapid pattern deposition, low material cost, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments.

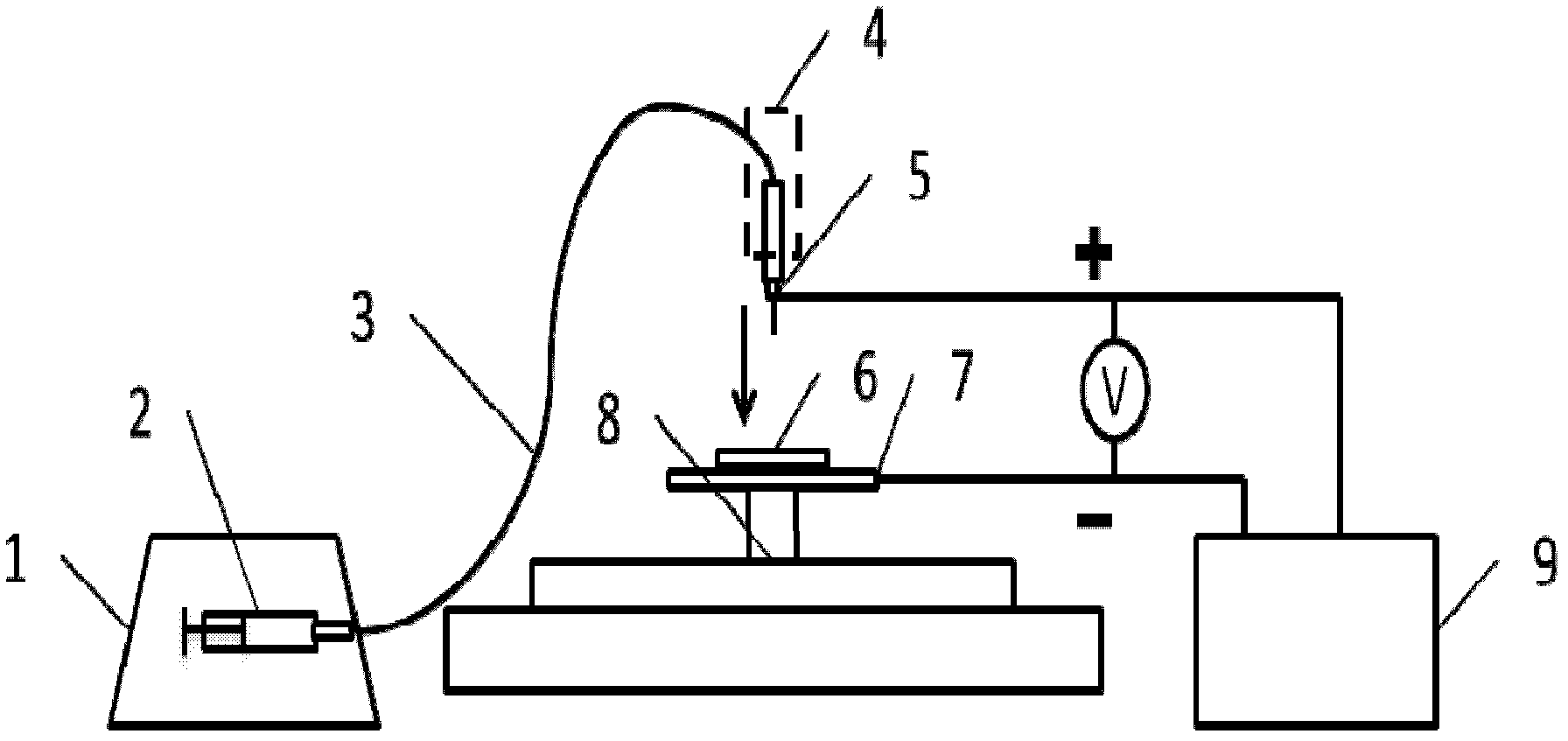

[0035] The arrayed pattern jet printing device of the present invention includes a flow pump 1, a syringe 2, a catheter 3, a metal needle 5, a printing layer 6, a metal substrate 7, an X-Y motion platform 8 and a high-voltage generator 9, in which,

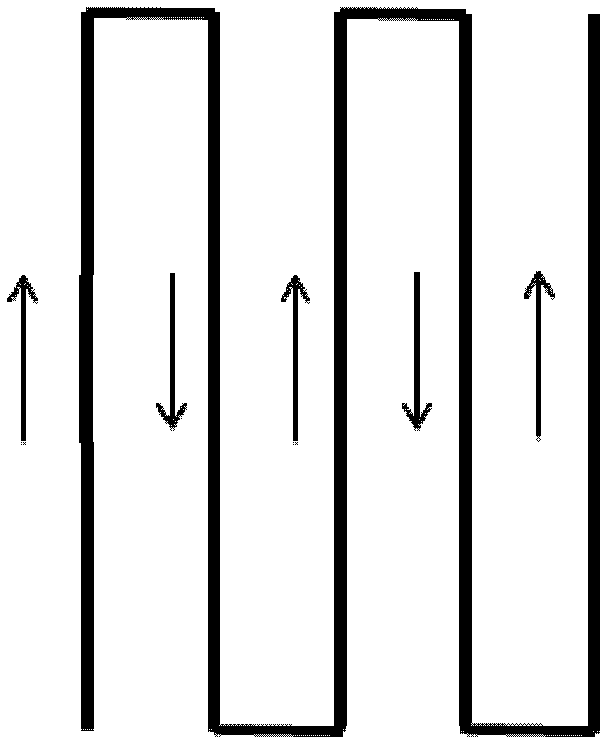

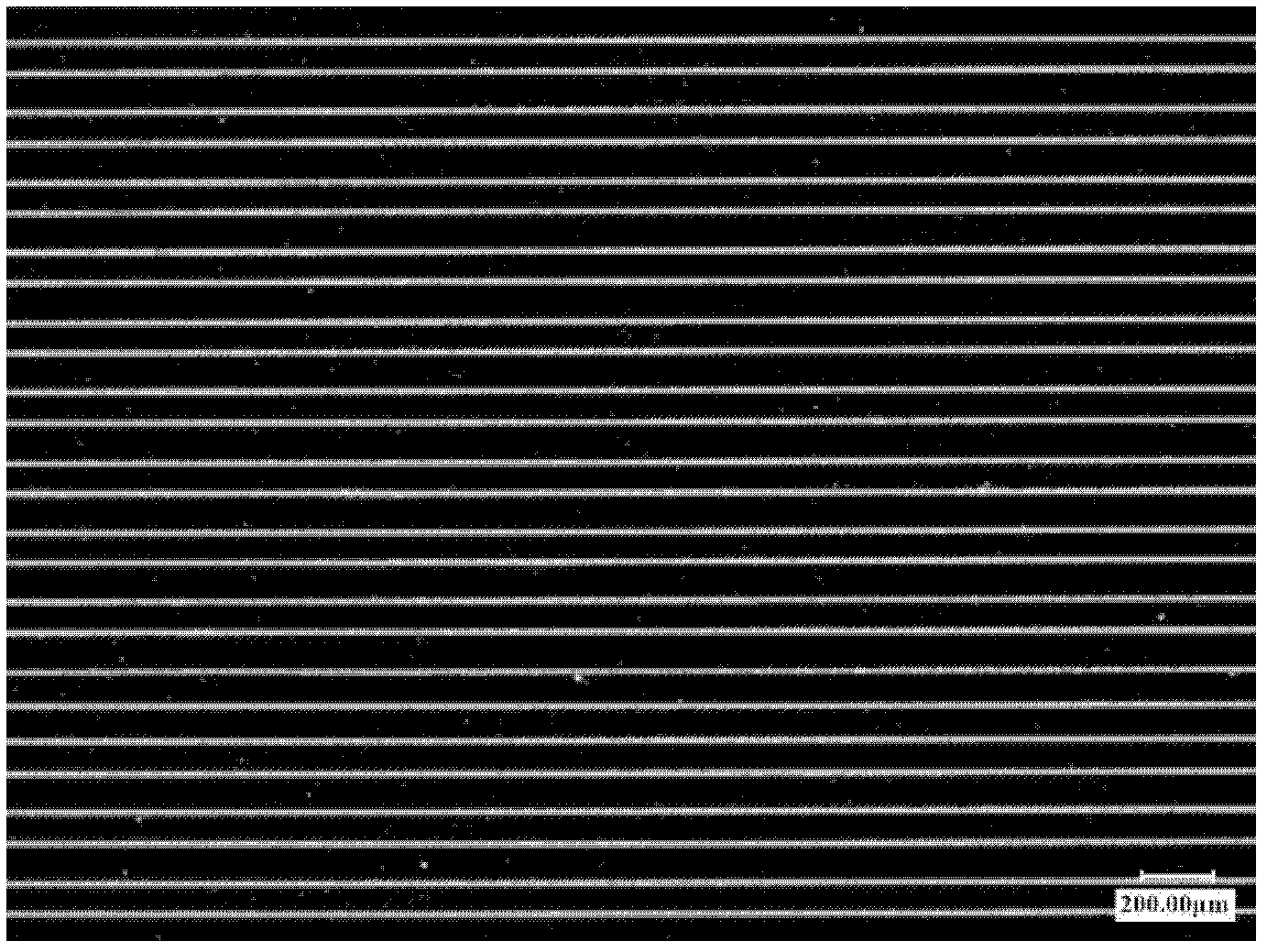

[0036] The metal needle 5 is arranged above the metal substrate 7, and the two are respectively connected to the positive and negative ends of the high-voltage generator 9 to form an electric field between the metal needle 4 and the metal substrate 7. The metal needle 5 passes through the conduit 3 and the flow pump 1 Connected, the metal substrate 7 is set on the XY moving platform 8, the printing solution enters the metal needle 5 through the flow pump 1, and forms a jet under the action of the electric field and falls on the substrate 7. At the same time, the metal substrate 7 follows the XY moving platform 8 makes a tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com