Process and mould device for making small pecan shell artware

A production process, a technology for pecans, applied in decorative arts, special decorative structures, etc., can solve the problems of unreasonable production process, simple and rough, perishable and easy to attract insect pests, etc., and achieves a high degree of automation, easy to control the shape, and easy to last. saved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

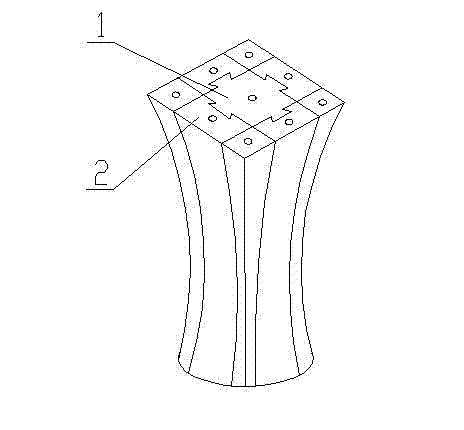

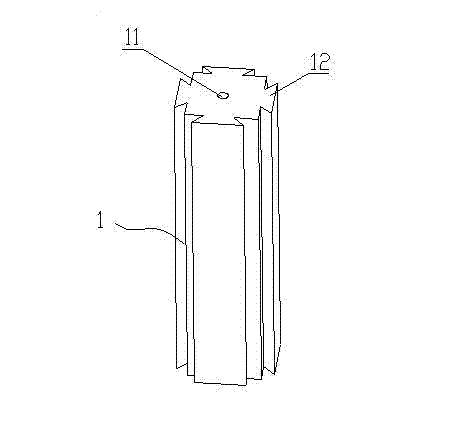

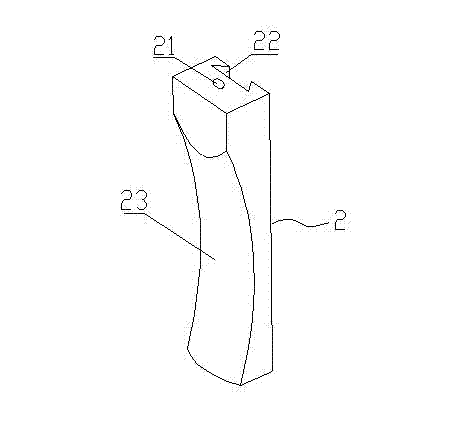

[0031] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0032] A kind of manufacture craft of hickory nut shell handicraft, realizes through the following steps:

[0033] (1) Select the gaps in the small hickory nuts, and clean up the defective products that are too small, rotten, or severely damaged. (2) Soak the processing object in clean water at 20°C for 2 hours, and drain the water. (3) Position the small hickory nuts with an elastic clamp and cut them on a cutting machine to obtain sliced bodies. (4) Dry the cut shell slices until the water content is equal to 10%. (5) Use a wire brush made of steel wire with a diameter of 0.3 mm to clean the soft debris inside the hickory, that is, to clean the mussels. (6) Adhesive assembly is carried out on the surface of the combined mould, and the bottom and closing parts are reinforced with steel bars with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap