Method for treating doxycycline waste water with iron-modified attapulgite adsorbent

A technology of attapulgite and doxycycline, which is applied in the directions of adsorption water/sewage treatment, separation method, water/sewage treatment, etc., to achieve the effects of high regeneration efficiency, easy promotion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Weigh 5g of purified attapulgite into a 500mL beaker, add 250mL of distilled water, and after magnetic stirring for 0.5h, add 0.724g of FeCl 3 ·6H 2 O (equivalent to 0.15gFe), magnetic stirring for 30min, to ensure FeCl 3 ·6H 2 O is completely dissolved, adjust the pH value=7, continue to stir for 1h, centrifuge and wash 3 times, then dry at 40℃ for 36-48h, and grind to a particle size ≤100 mesh to prepare iron-modified attapulgite adsorbent.

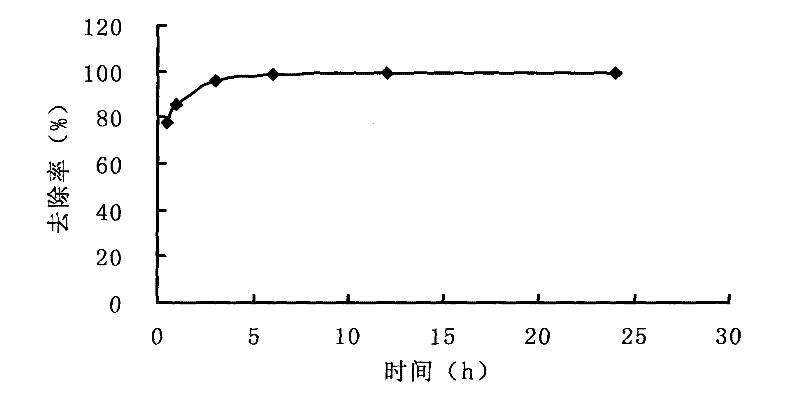

[0049] Accurately weigh 0.1000g (±0.0005g) of iron-modified attapulgite adsorbent, put it in a 250mL conical flask with stopper, add 20mL doxycycline solution with a concentration of 100mg / L, and place it in a constant temperature oscillator Inside, oscillate at a rate of 150r / min at a temperature of 25℃. Take the supernatant and pass it through a 0.45μm microporous membrane at 1h, 3h, 6h, 12h, and 24h, and test the residual doxycycline concentration by liquid chromatography. Three parallels are set for each group of experiments, and...

Embodiment 2

[0052] As in Example 1, an iron-modified attapulgite adsorbent was prepared.

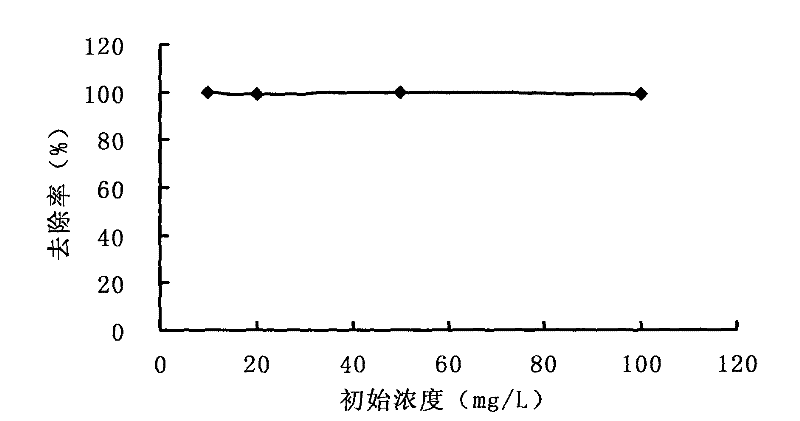

[0053] Accurately weigh 0.1000g (±0.0005g) of iron-modified attapulgite adsorbent, put it in a 250mL conical flask with stopper, and add 20mL of doxycycline solution with concentrations of 10, 20, 50, 100 mg / L, respectively Place it in a constant temperature oscillator and oscillate at a rate of 150r / min at 25°C for 24 hours to reach adsorption equilibrium. Take the supernatant and pass it through a 0.45μm microporous membrane. Use liquid chromatography to test the concentration of residual doxycycline. Three parallels are set for each group of experiments, and the results are expressed as the arithmetic mean, and the standard deviation is calculated to ensure the test accuracy. After calculation, the adsorption removal rate of doxycycline was 99.9%, 99.2%, 99.6%, and 99.4%, respectively. Attached figure 2 , The effect of initial concentration of doxycycline on adsorption removal rate.

[0054] It can...

Embodiment 3

[0056] As in Example 1, an iron-modified attapulgite adsorbent was prepared.

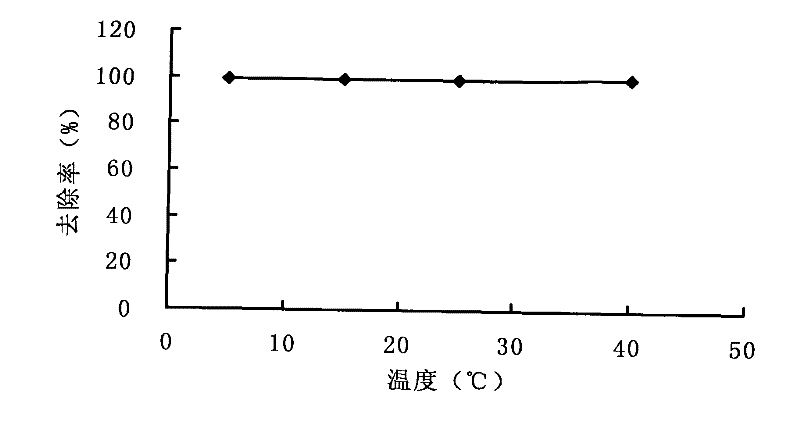

[0057] Accurately weigh 0.1000g (±0.0005g) of iron-modified attapulgite adsorbent, put it in a 250mL conical flask with stopper, add 20mL doxycycline solution with a concentration of 100mg / L, and place it in a constant temperature oscillator In the inside, oscillate at a rate of 150r / min at 5, 15, 25, and 40°C for 24 hours to reach adsorption equilibrium, take the supernatant through a 0.45μm microporous membrane, and use liquid chromatography to test the concentration of residual doxycycline. Three parallels are set for each group of experiments, and the results are expressed as the arithmetic mean, and the standard deviation is calculated to ensure the accuracy of the test. After calculation, the adsorption removal rate of doxycycline was 99.1%, 99.3%, 99.4%, and 99.8%, respectively. Attached image 3 , The effect of temperature on adsorption removal rate.

[0058] It can be seen that the adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com