Ardealite basis composite gelled material and coagulant thereof

A technology of composite cementitious material and phosphogypsum, which is applied in the field of phosphogypsum-based composite cementitious material and its coagulant, can solve the problems of low strength, limited wide use, high energy consumption, etc., achieve excellent waterproof performance and broad development prospects , The effect of reducing the stacking pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

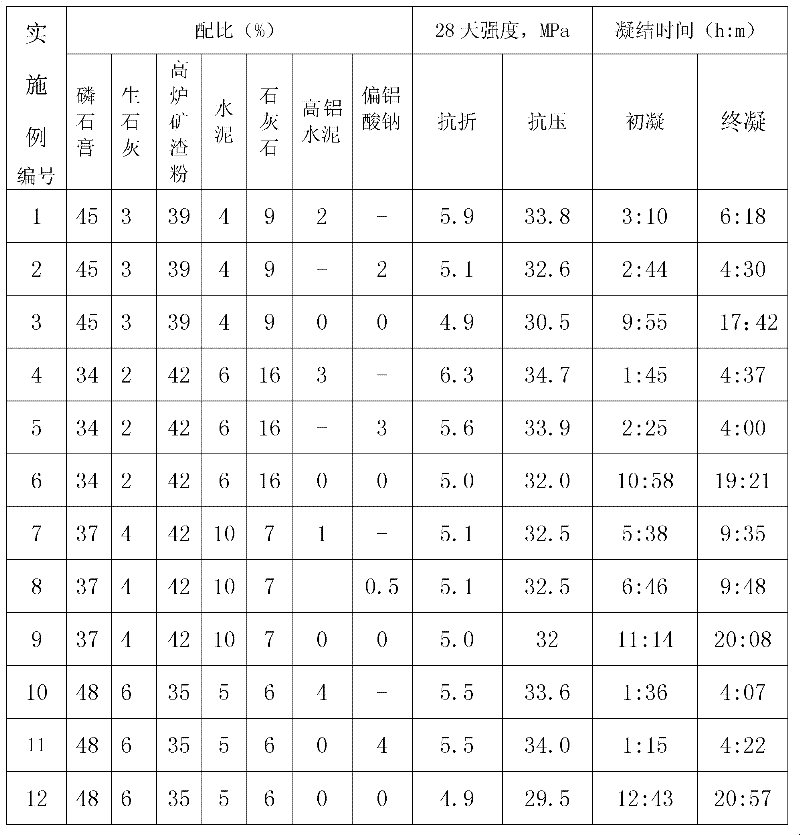

[0011] The phosphogypsum used in the present invention is phosphogypsum discharged from the production of diammonium phosphate by Anhui Liuguo Chemical Co., Ltd. using low-grade Yichang phosphate rock. The specific components are as follows:

[0012] CaO: 29.22%, SO 3 : 44.10%, P 2 O 5 : 1.02%, F: 1.28%, SiO 2 : 2.51%, Al 2 O 3 : 0.81%, Fe 2 O 3 : 1.05%, MgO: 1.37%, Na 2 O: 0.36%

[0013] The various embodiments of the present invention are carried out according to the following process: the phosphogypsum after the initial breaking is removed most of the free water in the drying kiln, and the content of the free water is controlled not to be more than 1%. Take the dry-based phosphogypsum, blast furnace slag powder, Portland cement, limestone powder, quicklime, high alumina cement or sodium metaaluminate after the above-mentioned drying according to the proportions of the components in the examples in the following table. The specific surface area is as fine as 200 meshes to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com