Poly fatty acid shape-stabilized phase change material and preparation method thereof

A technology of shape-setting phase change materials and polybasic fatty acids, which is applied in the production of ceramic materials, materials for heat exchange, chemical instruments and methods, etc. , the effect of increasing the adsorption capacity and improving the energy saving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

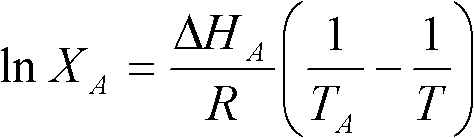

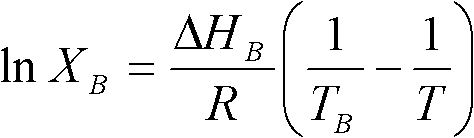

[0037] (1) According to Schroeder's formula, the optimal mixing mass ratio of myristic acid and stearic acid is calculated to be 72.66%: 27.34%, and myristic acid and stearic acid are mixed according to the proportion, and the two are mixed under the condition of 85 ℃ of water baths. The fatty acid mixture was heated and stirred for 50 minutes, and myristic acid / stearic acid binary eutectic mixture was obtained after ultrasonication for 3 minutes.

[0038] (2) Measure the binary eutectic mixture of myristic acid / stearic acid by differential scanning calorimetry, the phase transition temperature is 47.55°C, the phase transition latent heat is 182.3J / g, and its theoretical molecular mass is calculated to be 241.39; The dibasic fatty acid eutectic mixture is regarded as a single fatty acid, and then compounded with lauric acid. According to Schroeder's formula, the optimum mixing mass ratio of dibasic fatty acid eutectic mixture and lauric acid is 49% / 51%. ; After mixing accordin...

Embodiment 2

[0041] (1) Calculate the mixing mass ratio of lauric acid and myristic acid according to Schroeder's formula to be 65.08%: 34.92%, mix lauric acid and myristic acid according to the proportion, and mix the mixture of these two fatty acids under 65°C water bath condition Heated and stirred for 60 minutes, and ultrasonicated for 2 minutes to obtain a binary eutectic mixture of lauric acid / myristic acid.

[0042] (2) Measure the binary eutectic mixture of lauric acid / myristic acid by differential scanning calorimetry, the phase transition temperature is 35.10°C, the latent heat of phase transition is 210.2J / g, and its theoretical molecular mass is calculated to be 209.30; The dibasic fatty acid eutectic mixture is regarded as a single fatty acid, and then compounded with capric acid. According to Schroeder's formula, the optimal mixing mass ratio of dibasic fatty acid eutectic mixture and capric acid is 47.6% / 52.4% ; After mixing according to the ratio, heat and stir it in a wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com