Preparation method for high molecular weight polylactic acid steric composite

A technology of stereocomplex and high molecular weight, which is applied in the field of polymer materials, can solve the problems of high cost, complicated post-processing, low yield, etc., and achieve the effect of improving heat resistance, simple and feasible process, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

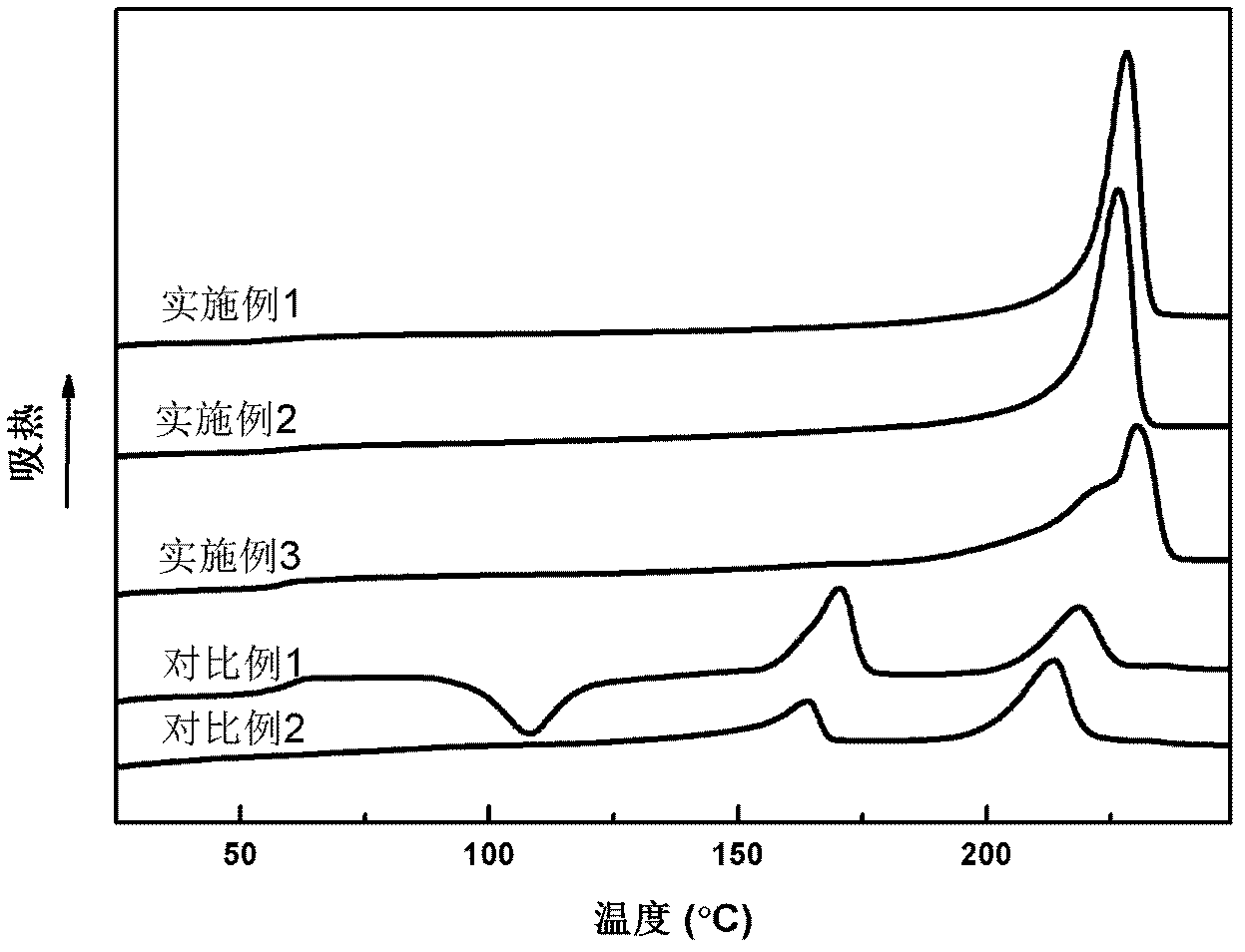

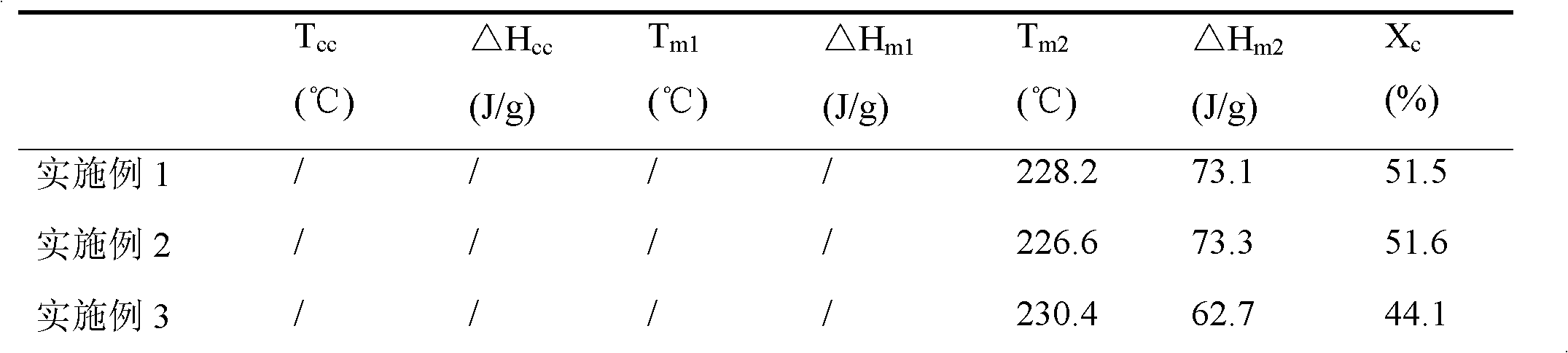

[0028] The poly-L-lactic acid and poly-D-lactic acid resins with a weight ratio of 50:50 were blended in a torque rheometer, the blending temperature was 140°C, the rotation speed was 40r / min, and the blending time was 15min. The resin was not plasticized during the preparation process, and the obtained sample was heated to 250°C by differential scanning calorimetry (DSC) at 10°C / min to melt. The results are shown in Table 1 and figure 1 .

Embodiment 2

[0030] The poly-L-lactic acid and poly-D-lactic acid resins with a weight ratio of 50:50 were blended in a torque rheometer, the blending temperature was 180°C, the rotation speed was 40r / min, and the blending time was 15min. The resin was not plasticized during the preparation process, and the obtained sample was heated to 250 °C by DSC at 10 °C / min to melt. The results are shown in Table 1 and figure 1 .

Embodiment 3

[0032] The poly-L-lactic acid and poly-D-lactic acid resins with a weight ratio of 50:50 were blended in a torque rheometer, the blending temperature was 210°C, the rotational speed was 40r / min, and the blending time was 15min. The resin was not completely plasticized during the preparation process, and the obtained sample was heated to 250°C by DSC at 10°C / min to melt. The results are shown in Table 1 and figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com