Lead melting device

A lead melting and feeding device technology, applied in the field of lead melting devices, can solve the problems of toxic gas polluting the environment and endangering human health, and achieve the effect of reducing the probability of lead slag and improving the vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

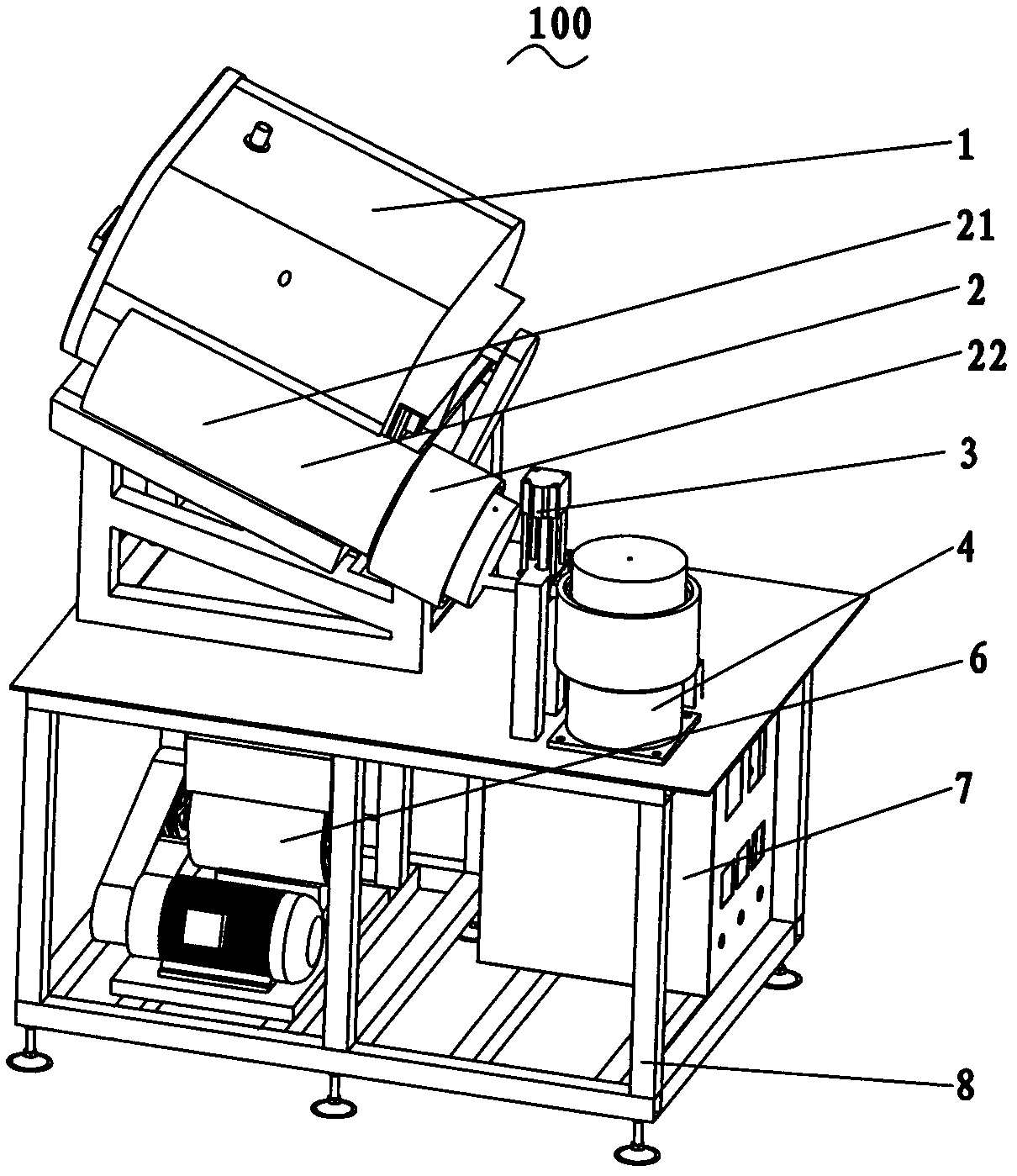

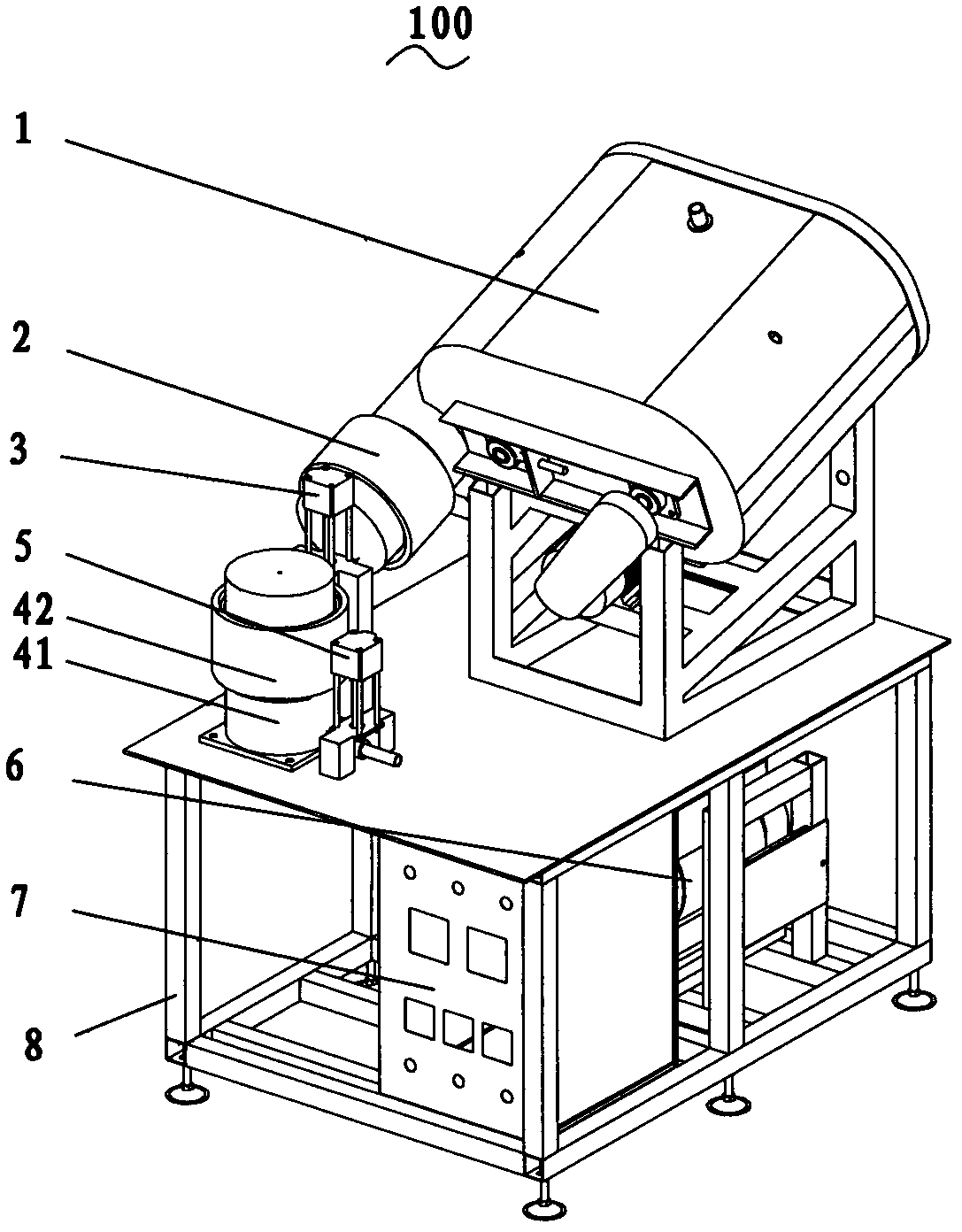

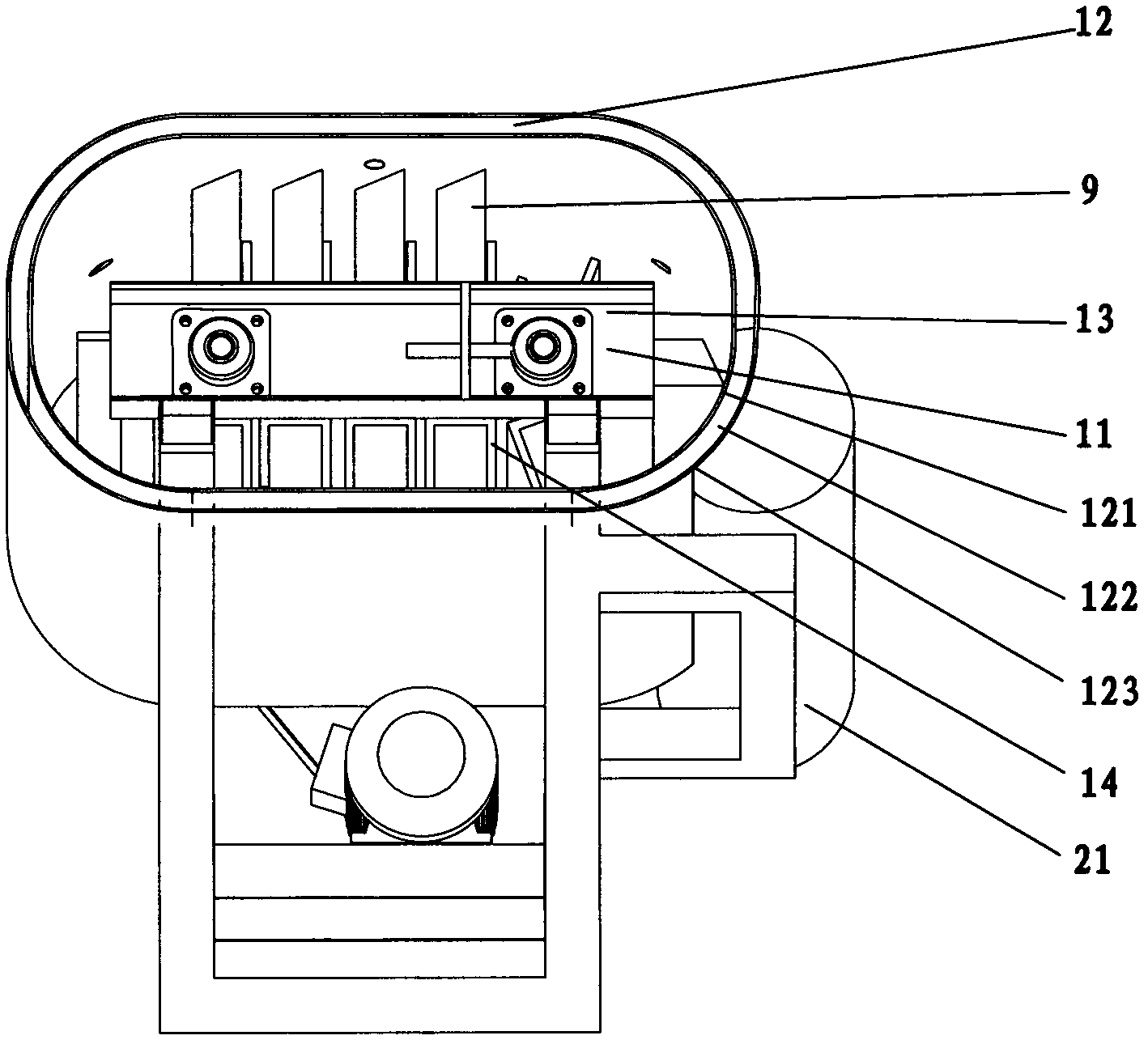

[0012] Please refer to Figure 1 to Figure 4 Shown is the preferred embodiment of the lead melting device of the present invention. The lead-melting device 100 comprises a material storage area 1, a first lead-melting area 2, a first lead-out valve 3, a second lead-melting area 4, a second lead-out valve 5, a vacuum system, a control cabinet 7, and a frame 8, The vacuum system includes a vacuum pump 6, a cooling pipe connected to the inlet of the vacuum pump, a filter and a negative pressure regulating valve.

[0013] The material storage area 1 provides the molten raw material for the first lead melting area 2, and the molten raw material in this embodiment is lead ingot. The melted lead ingots are placed in the storage area 1 in advance, and the production amount for one day or other certain period of time is stored at one time according to the production requirements, so as to ensure that the storage area 1 will not be opened for feeding during the production process.

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap