Ecotypic water-permeable stratum structure

An ecological and stratigraphic technology, applied in the field of stratum structure and ecological permeable stratum structure, can solve problems that are difficult to improve, deplete, and destroy the climate of urban agglomeration areas, and achieve the effects of reducing temperature, solving urban water accumulation, and solving heat island effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

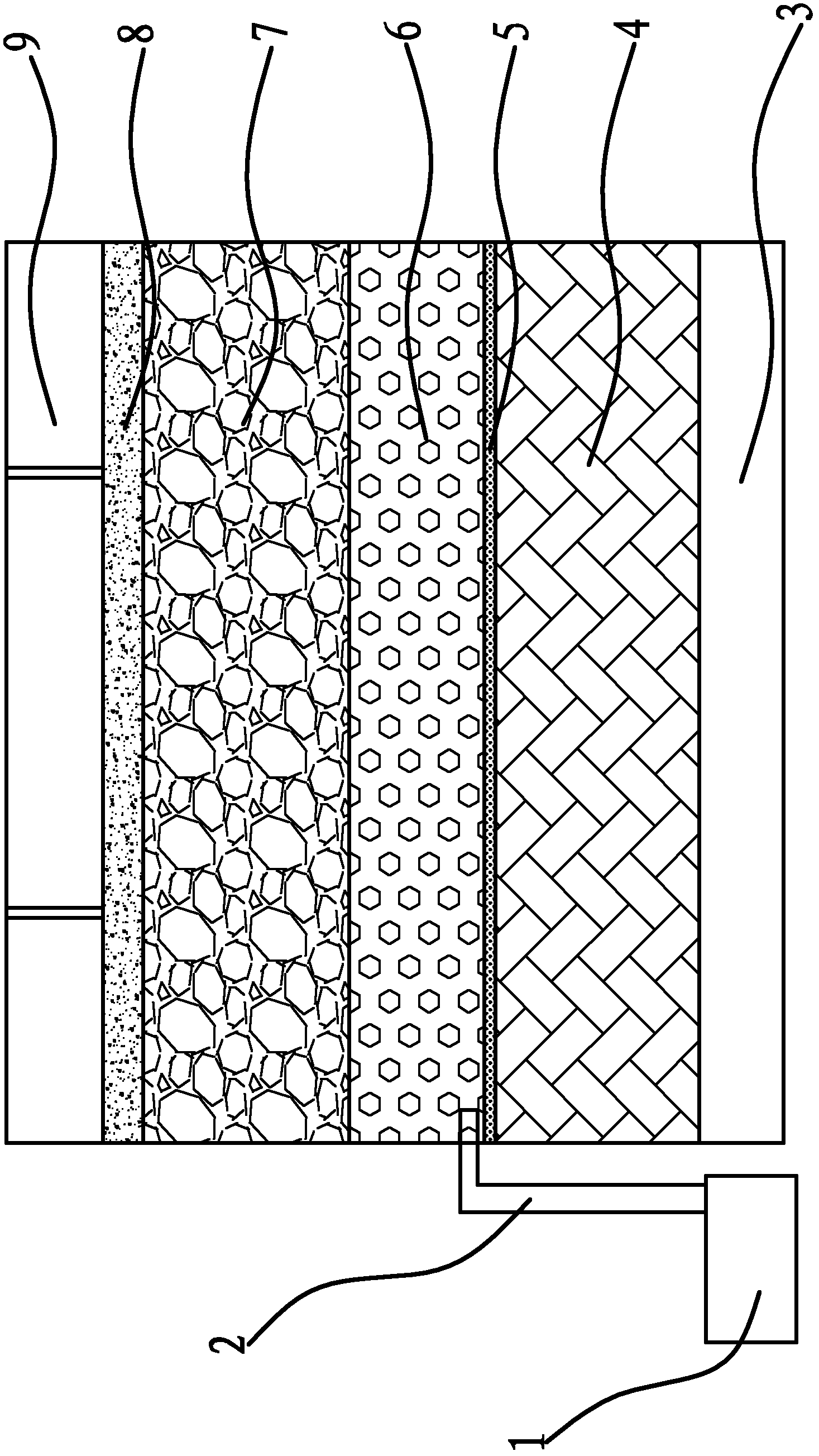

[0021] Such as figure 1 As shown, the eco-type permeable stratum structure includes an aquifer, a permeable layer and a surface layer that are tiled sequentially from bottom to top.

[0022] There is a basement 3 under the ground, and the aquifer includes a structural layer 4 that is laid on the top of the basement 3. The structural layer 4 is constructed of concrete materials to enhance its load-bearing strength. The structural layer 4 acts as a frame support for the load-bearing above the basement 3 . The top of the structural layer 4 is closely pasted with a waterproof layer 5 that is a high-efficiency waterproof material, so it can effectively prevent moisture from continuing to seep until it leaks from the top surface of the basement 3 . In the basement 3 or at the same level as the basement 3, a water storage tank 1 is provided. A drainage pipe 2 and a centrifugal water pump connected to the opening of the drainage pipe 2 are arranged in the inner cavity of the water st...

Embodiment 2

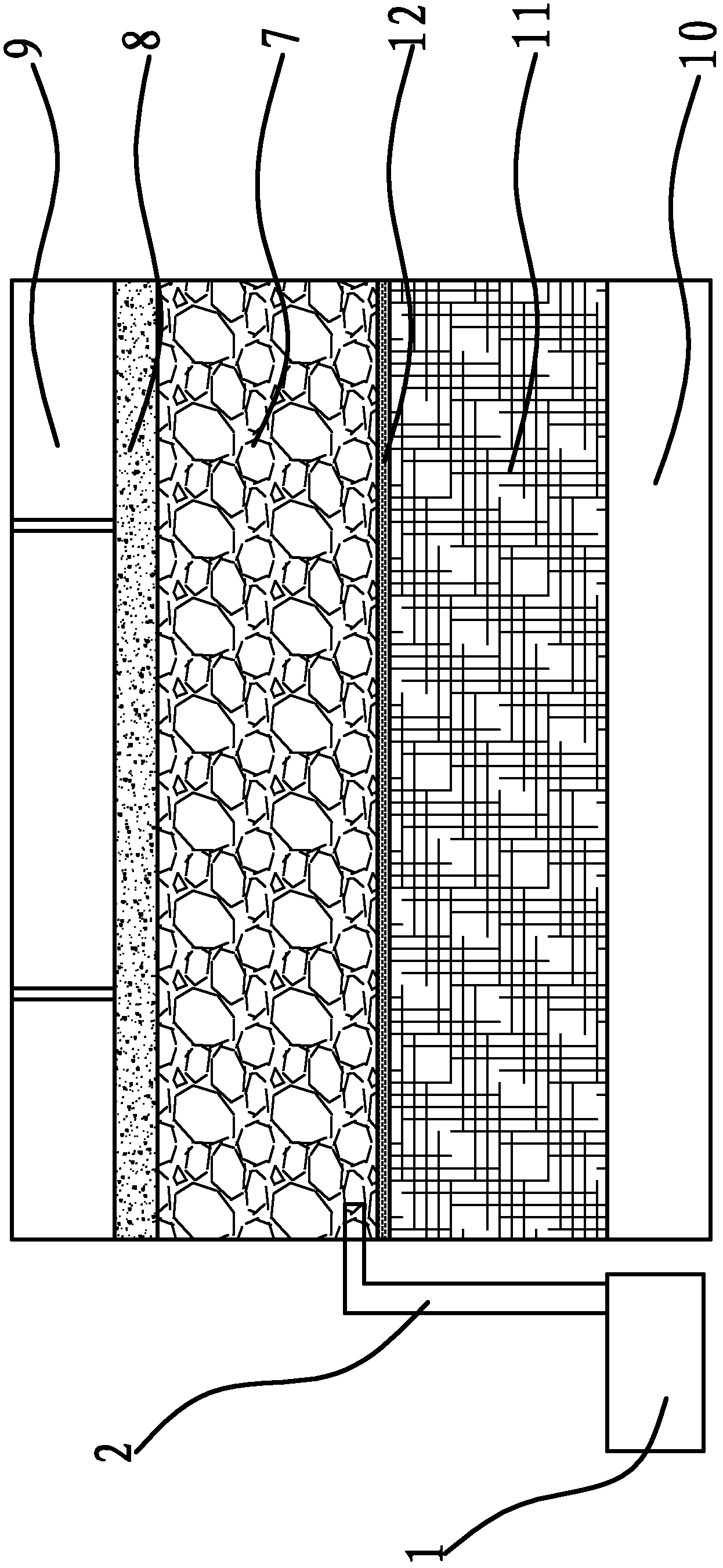

[0025] Such as figure 2 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: the reservoir 1 is reserved at the underground soil layer 10, and the upper side of the underground soil layer 10 is formed by using construction waste. Carry out filling pressure and leveling, thereby formed pond slag backfill layer 11, the upper side of pond slag backfill layer 11 lays the relatively cheap waterproof geotextile layer 12, and the upper side of waterproof geotextile layer 12 is poured greater than 150mm thick permeable concrete infiltration Layer 7 (strength ≥ C20), the upper side of the permeable concrete permeable layer 7 is laid closely with a 30-50mm thick paving layer 8, and finally the ecological pavement brick layer 9 is horizontally pasted on the upper side of the paving layer 8. A drainage pipe 2 connecting the water storage tank 1 and the permeable concrete permeable layer 7 is provided, and a centr...

Embodiment 3

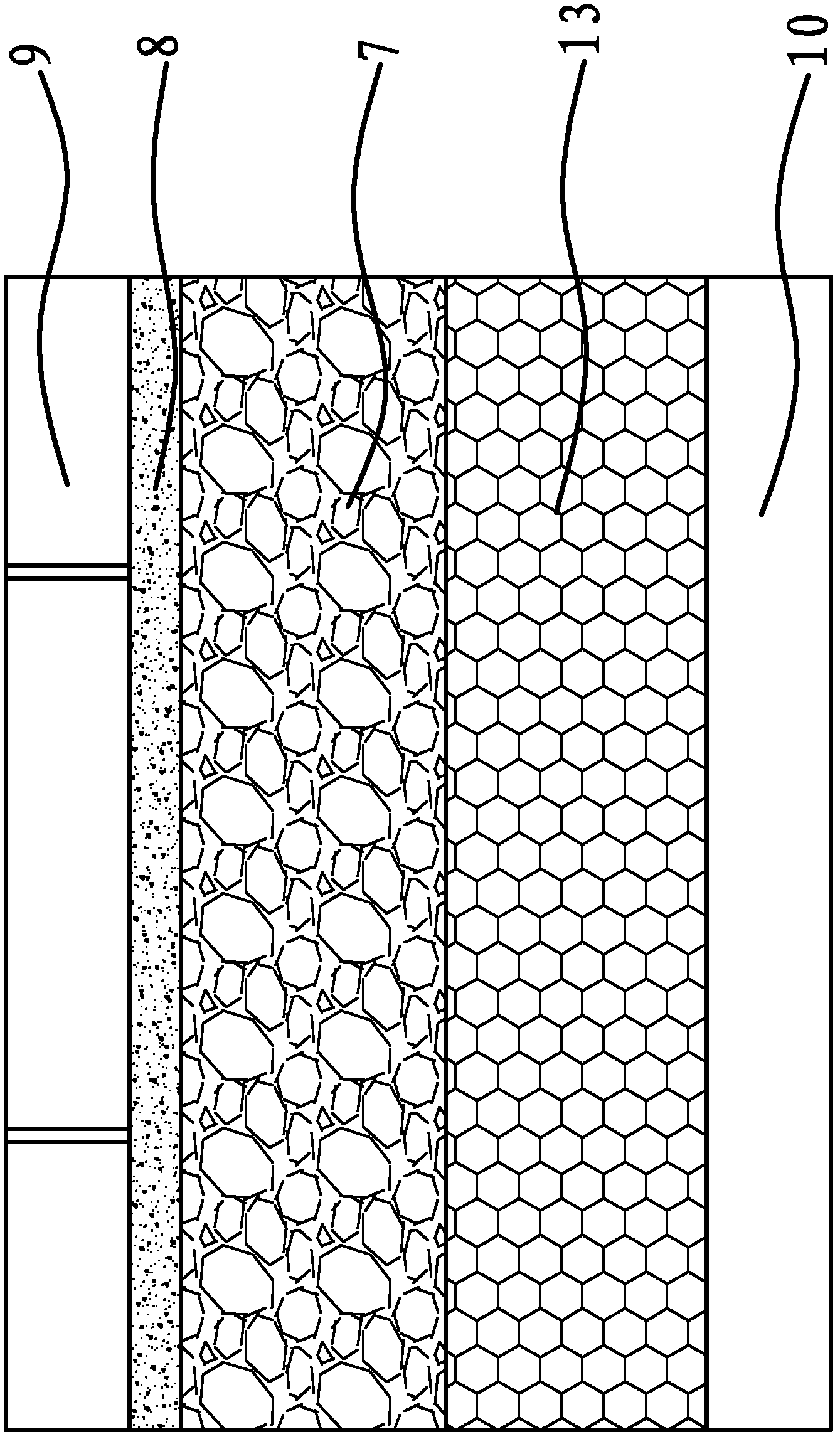

[0027] Such as image 3 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1 and Embodiment 2. The difference is that sand and gravel are laid on the upper side of the underground soil layer 10 for backfill compaction and leveling, and the sand thus formed Stone water storage layer 13, there are appropriate gaps in the particle gradation in this sandstone water storage layer 13, which is conducive to rainwater infiltration on the one hand, and also can store rainwater that has no time to infiltrate on the other hand. The upper side of the sand and gravel water storage layer 13 is closely pasted with a permeable concrete permeable layer 7 (strength ≥ C20) thicker than 150mm, and the upper side of the permeable concrete permeable layer 7 is closely pasted with a 30-50mm thick paving layer 8, and finally the The ecological pavement brick layer 9 is pasted horizontally on the upper side of the paving layer 8 .

[0028] When being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com