Double-layer highway bridge with integrated upper beam on frame mound and beam of polycarbonate (PC) continuous box girders

A technology for frame piers and highway bridges, applied in bridges, buildings, etc., can solve the problems of affecting the visual experience of drivers and passengers, large longitudinal and horizontal forces of double-deck bridges, and encroaching on the driving clearance, so as to achieve safe and reliable force bearing and bridge The surface deformation is small and the effect of reducing the scale of the pier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

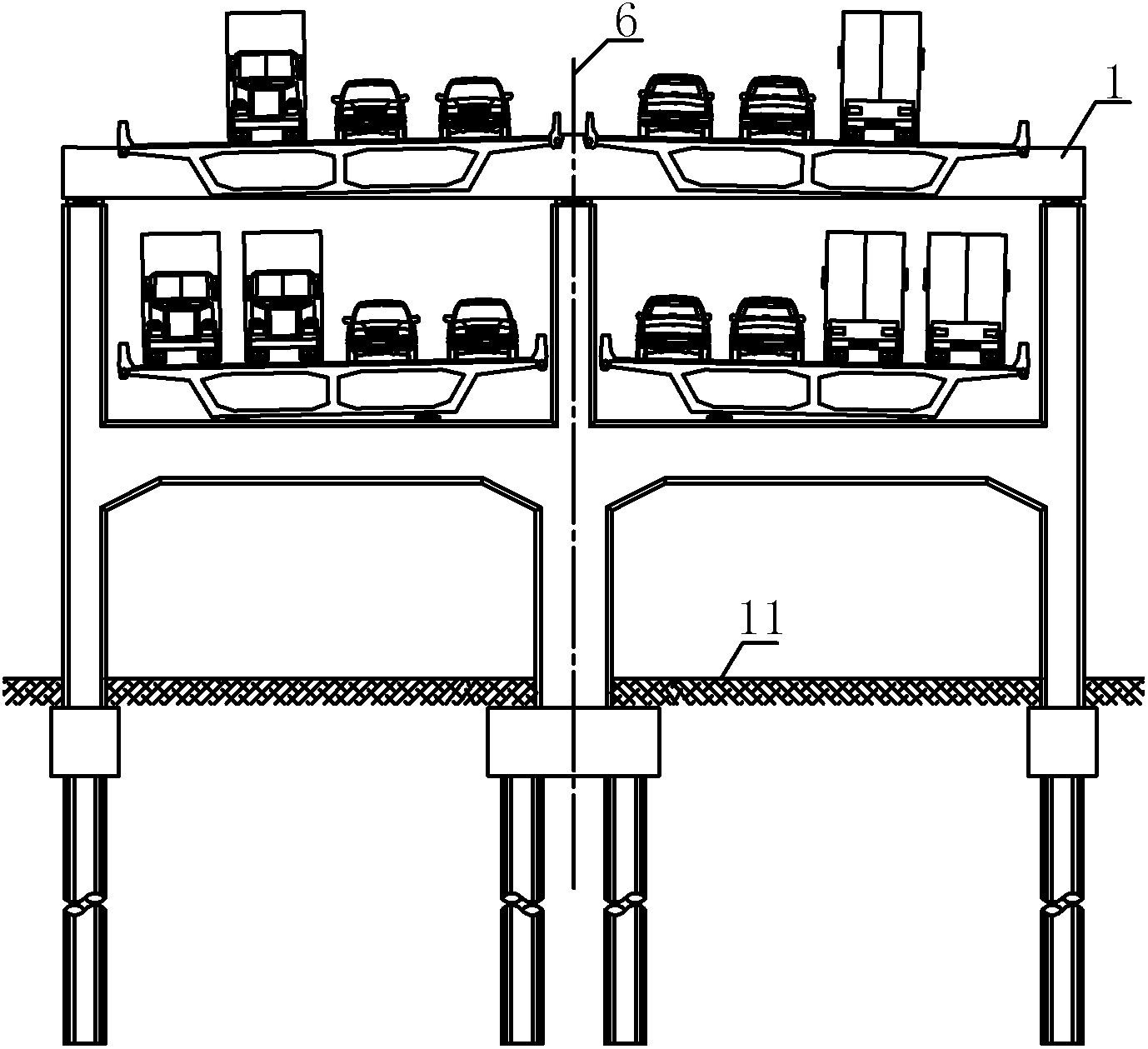

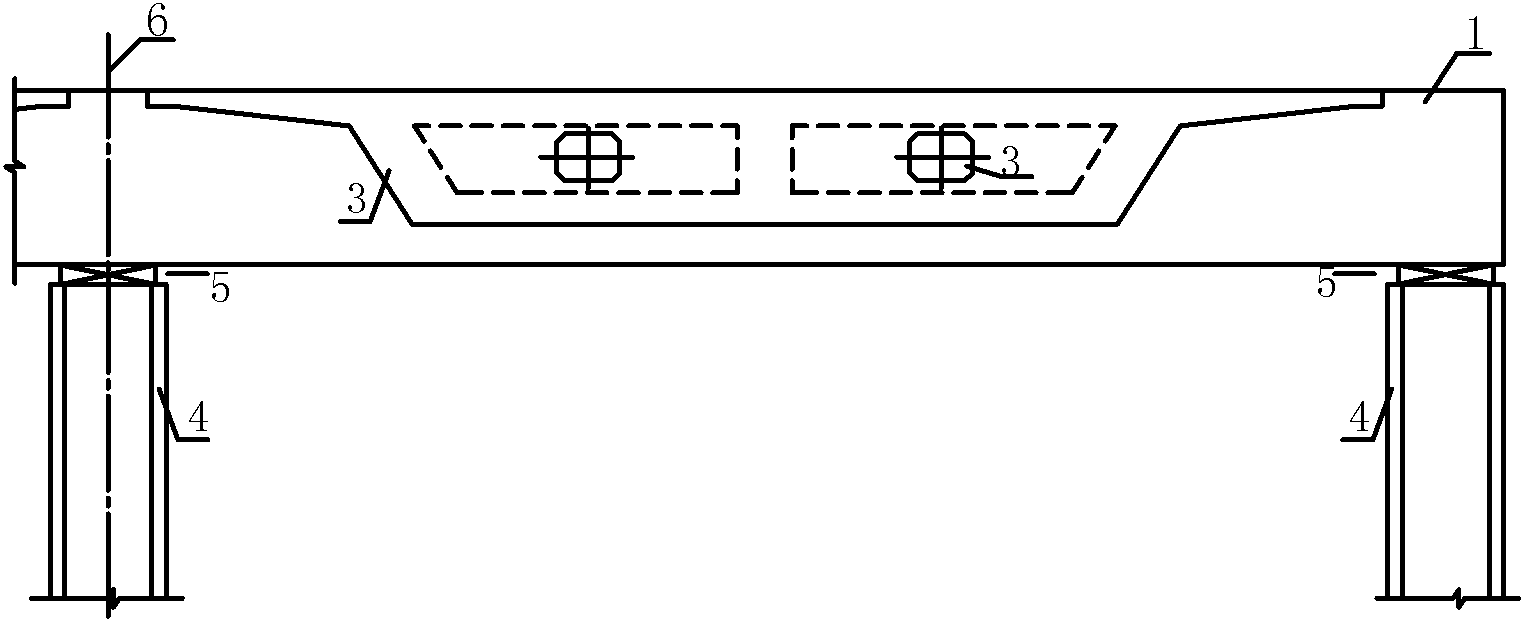

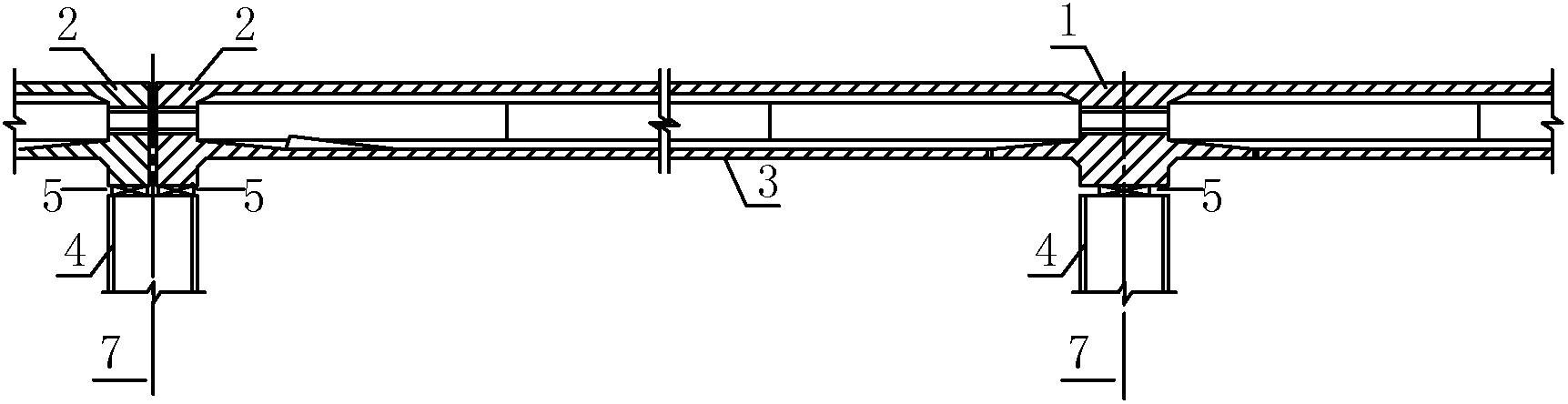

[0021] refer to figure 1 , 2 , 3, 4, there are two layers of PC continuous box girders on the frame pier 4 of the double-layer road bridge, the upper layer support 5 is arranged on the frame pier 4 of the double-layer road bridge, and the upper layer PC continuous box girder diaphragm on the upper layer support 5 is connected with the The beams on the top of the frame piers are integrated into one. In the figure, there are bridge pier horizontal bridge toward the center 6, bridge pier longitudinal bridge toward the center 7, line center 8, and ground 11.

[0022] The structure in which the PC continuous box girder diaphragm beam of the upper layer and the frame pier top beam are integrated is a prestressed reinforced concrete structure, the length of which is equal to the width of the frame pier cross bridge, and runs through the entire width of the bridge transversely.

[0023] The frame pier 4 of the double-layer highway bridge is a light-duty bent pier frame structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com