Water jet sprayer assisting offshore platform in sinking pile

An offshore platform, water jet technology, applied in the direction of sheet pile walls, injection devices, liquid injection devices, etc., can solve the problem of large pile diameter and achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

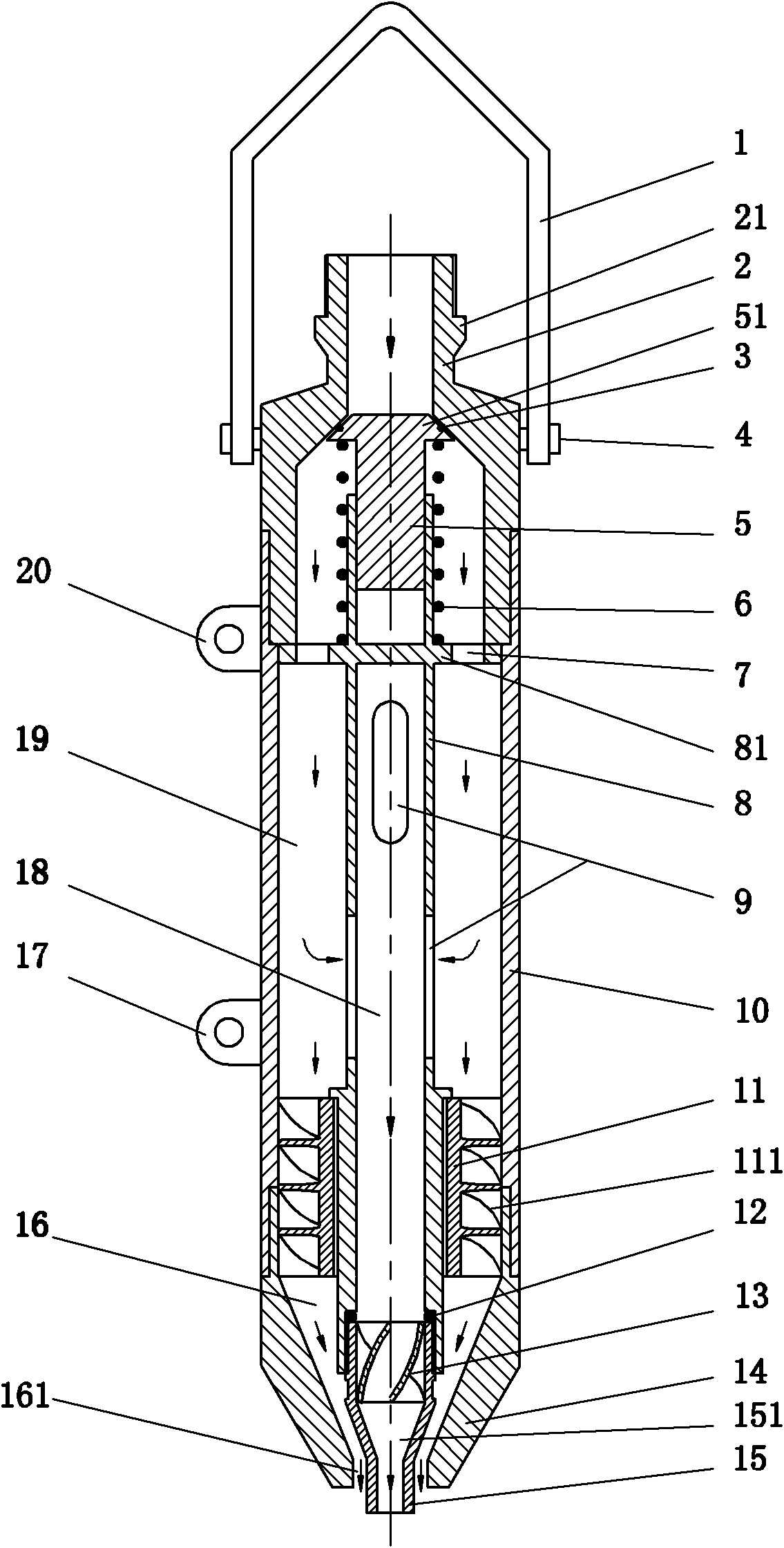

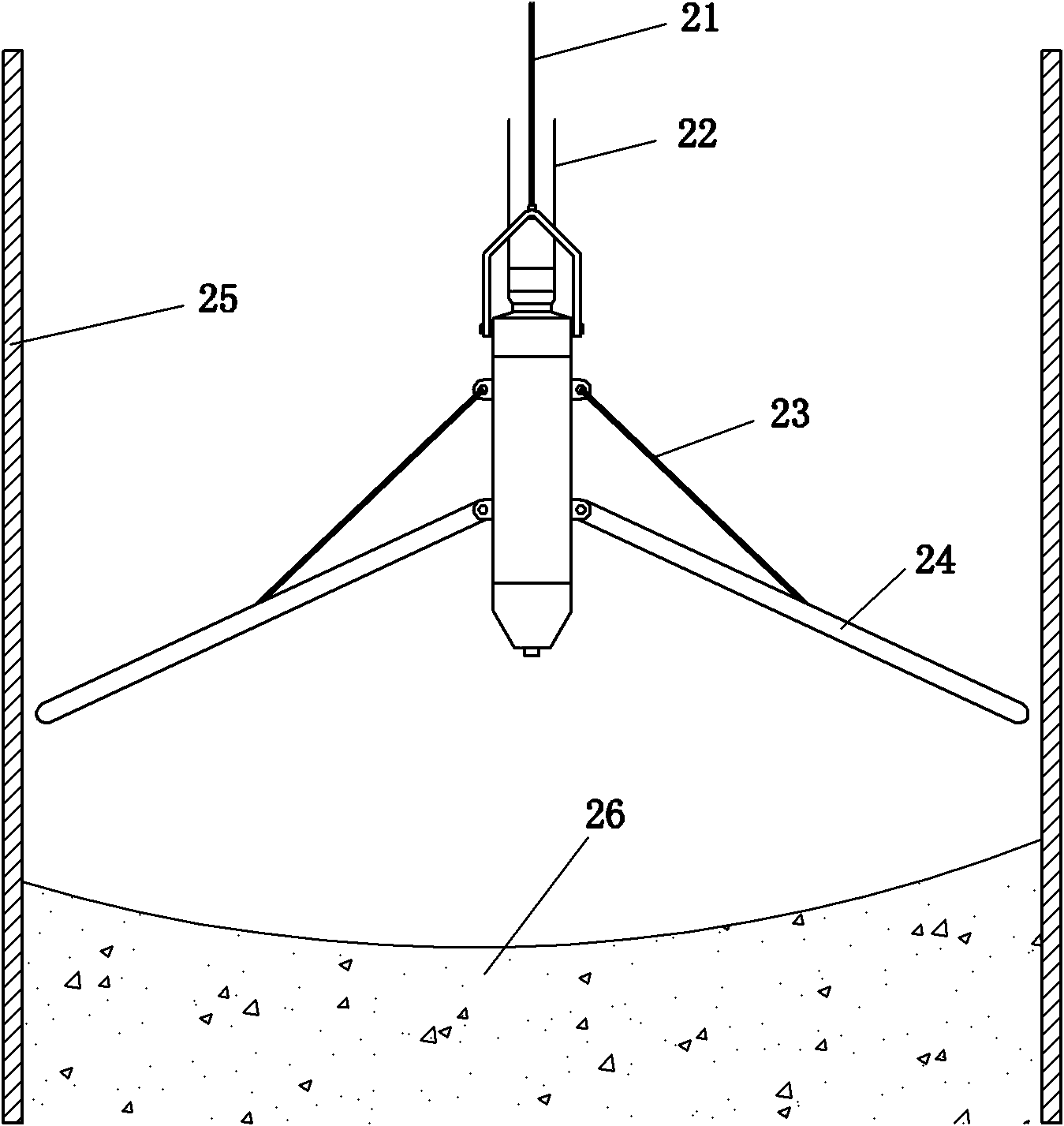

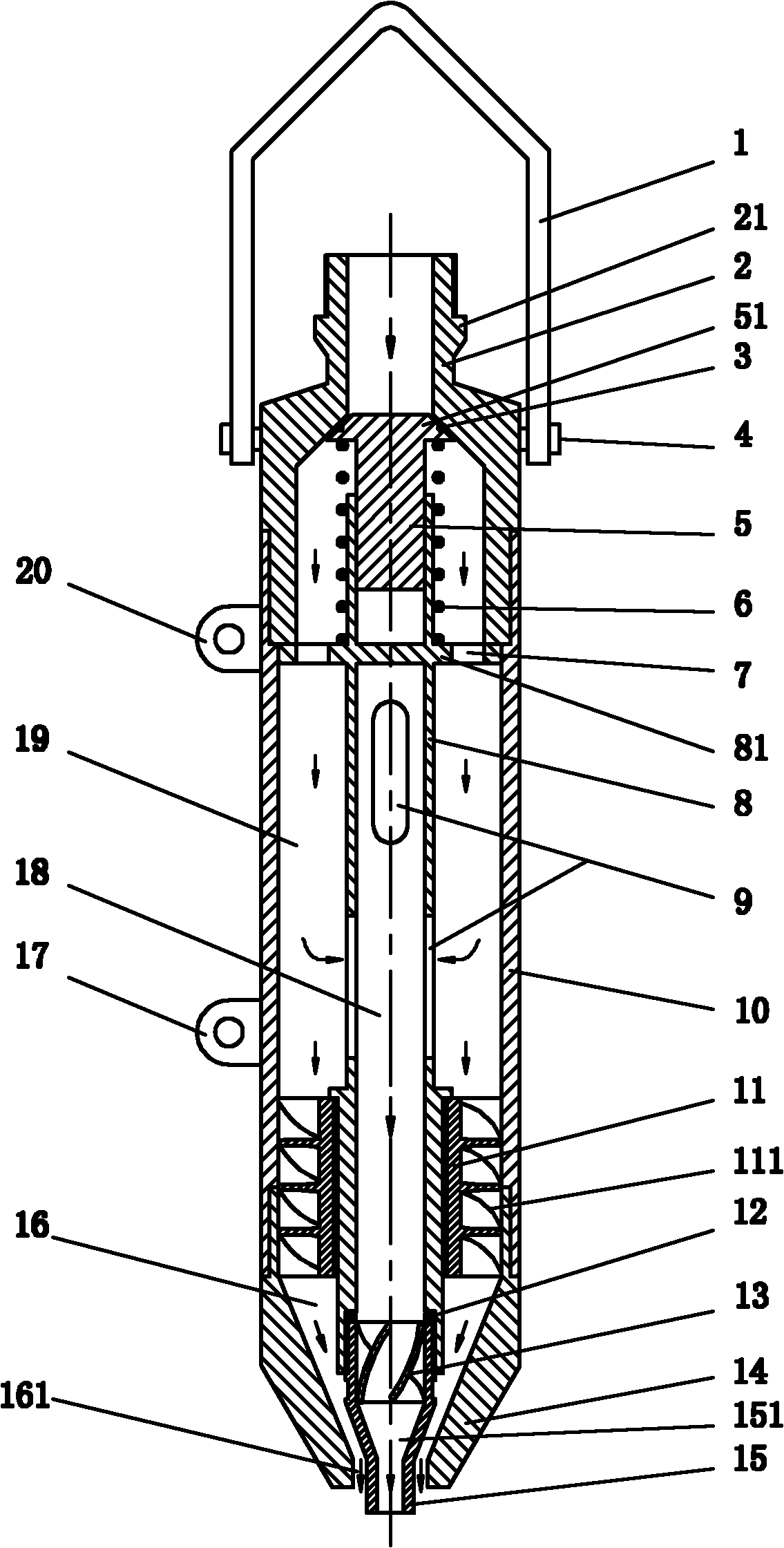

[0022] Such as figure 1 As shown, the offshore platform auxiliary pile sinking water jet nozzle includes: a cylinder body, the cylinder body has a hollow cylinder cavity 19, and the upper end of the cylinder body is provided with a water inlet connected to the cylinder cavity 19. The lower end of the cylinder body is provided with a water outlet connected to the cylinder cavity 19; the core tube 8 arranged in the cylinder cavity, the core tube 8 has a hollow core tube cavity 18, and the top of the core tube 8 A non-return valve 5 for selectively blocking the water inlet is provided, and an annular baffle 81 perpendicular to the axial direction of the core pipe 8 is provided on the core pipe 8 below the non-return valve 5 . The annular baffle 81 is provided with a plurality of water passage holes 7, and the tube wall of the core tube 8 located below the annular baffle 81 is provided with a plurality of water passages 9 extending along the axial direction of the core tube 8. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com