Stone cellular board and manufacturing process thereof

A technology of stone honeycomb panel and manufacturing process, which is applied in the direction of building construction, lamination, layered products, etc., can solve the problems of increasing maintenance and after-sales service costs, wasting material environment, and difficult processing, so as to save natural stone resources and reduce Effects of environmental pollution and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

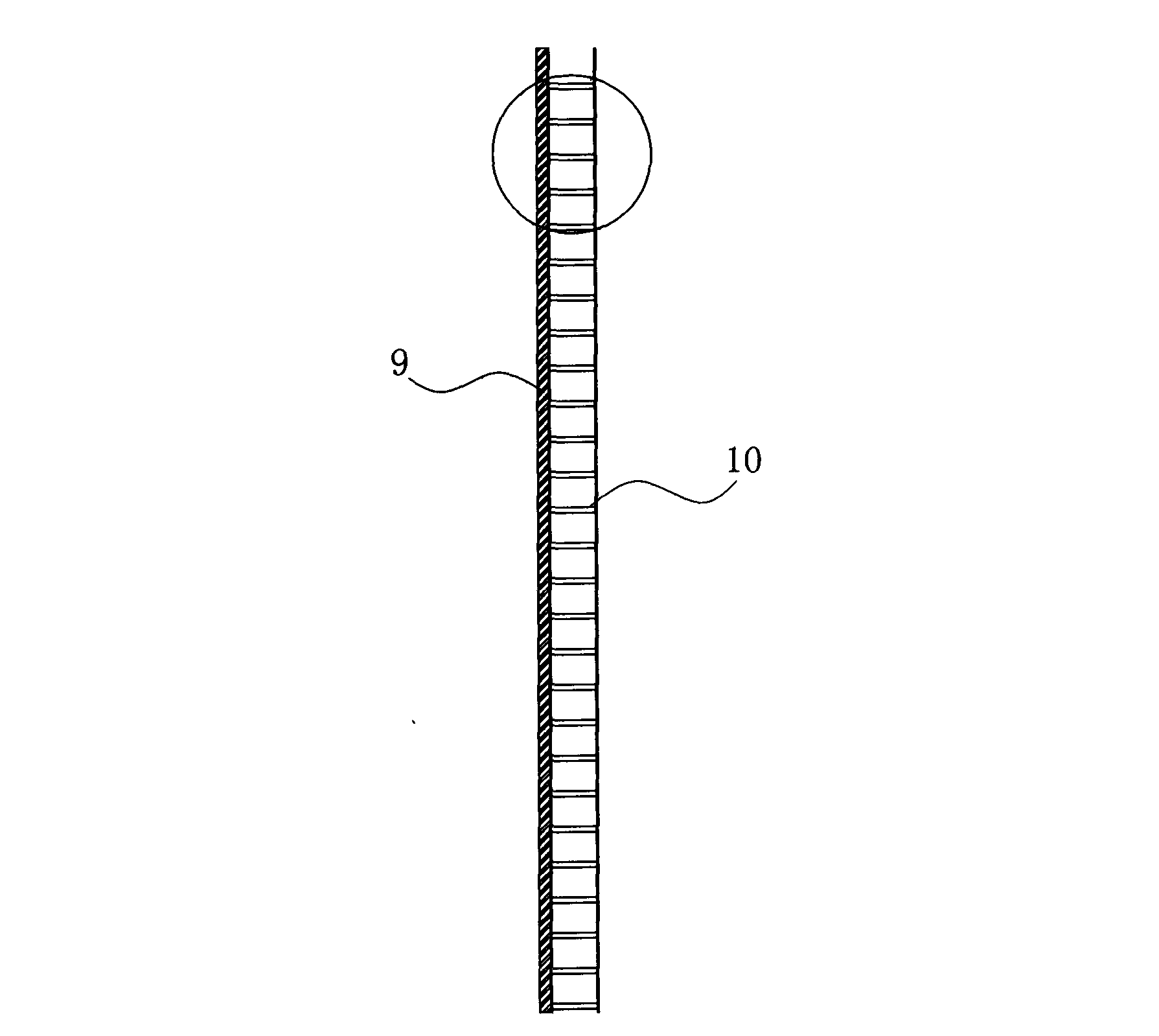

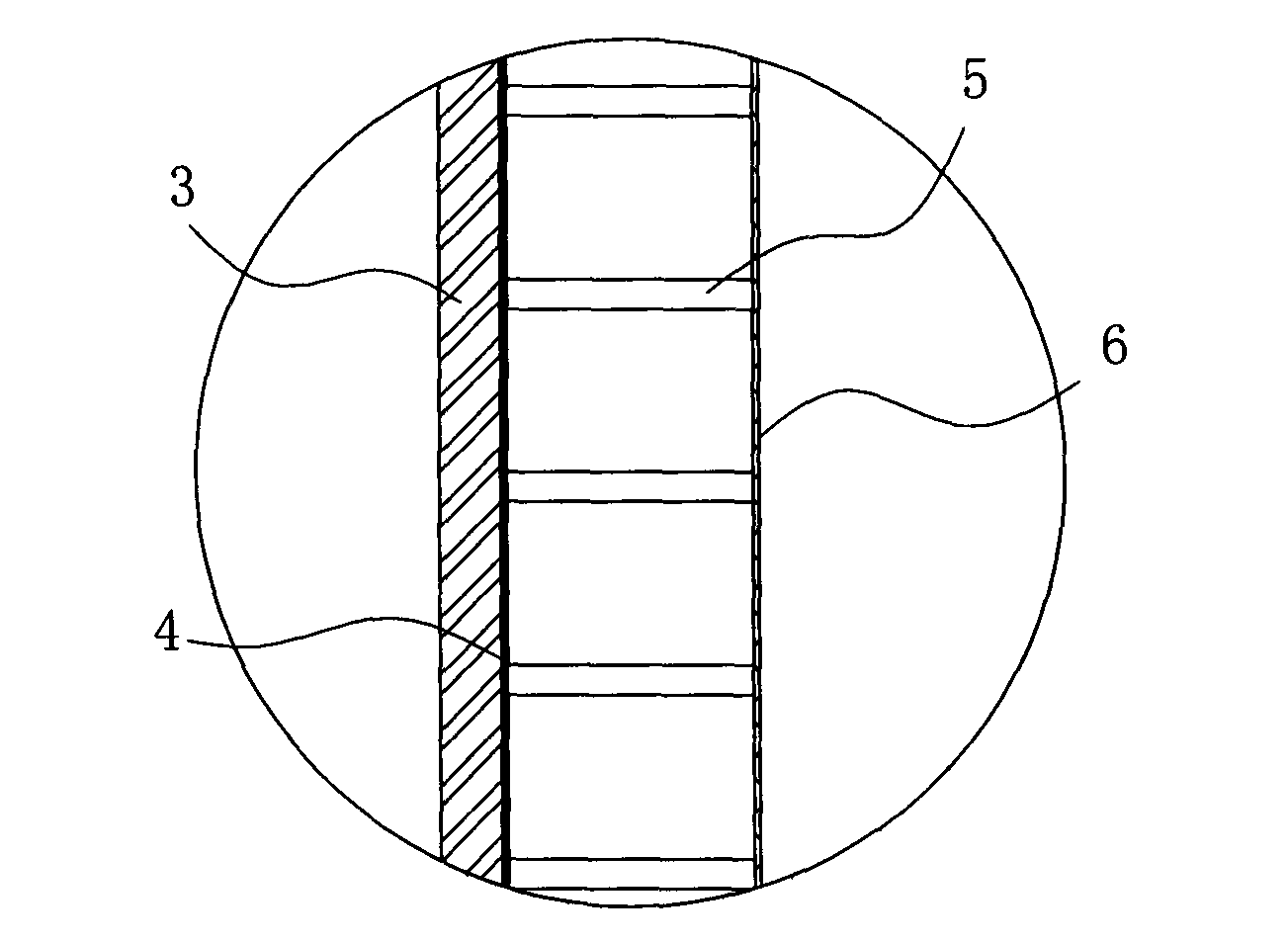

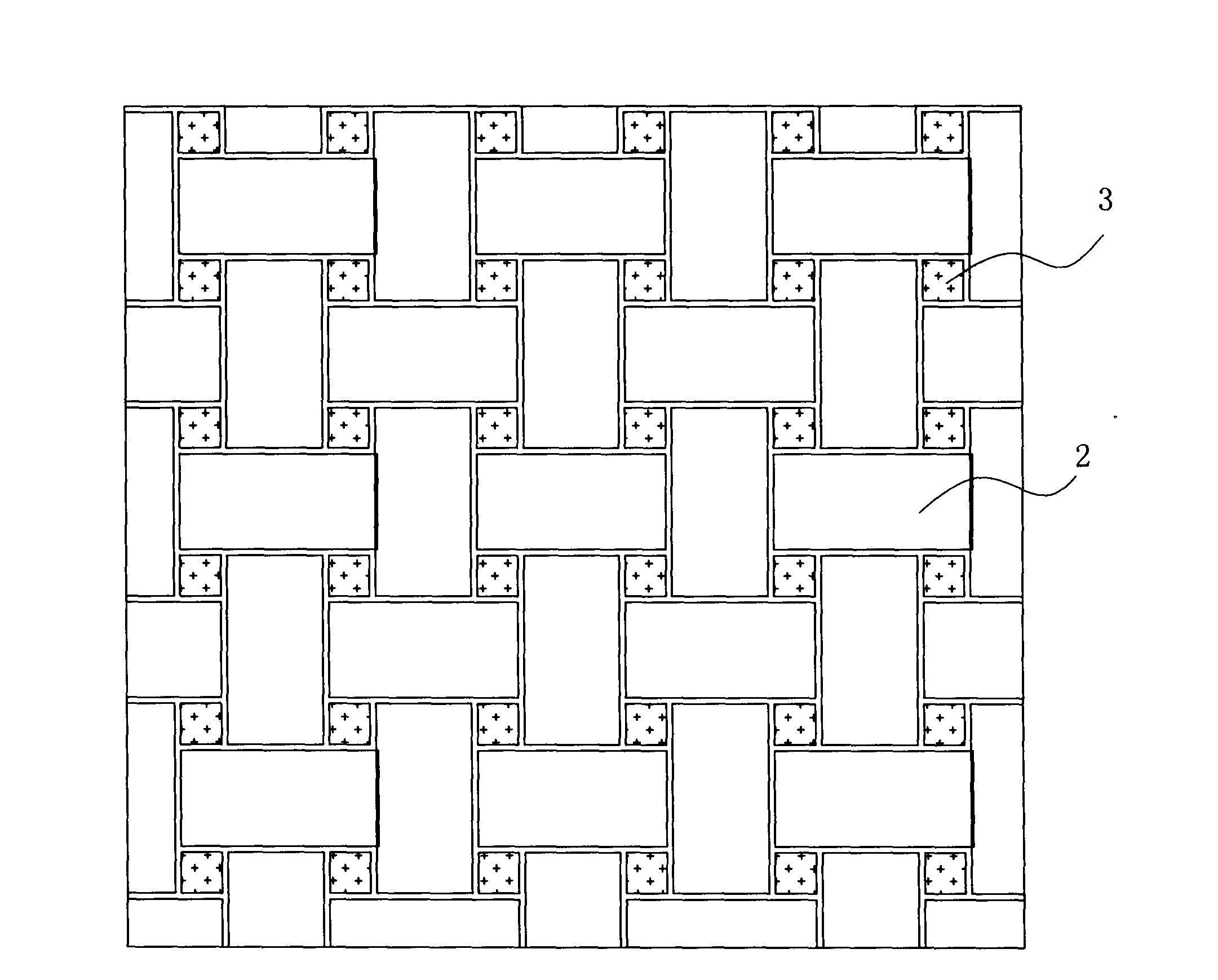

[0032] Embodiment one: see Figure 1~3 As shown, a stone honeycomb panel includes a stone panel 9 and a honeycomb substrate 10, both of which are compositely bonded to form an integrated structure. The stone panel 9 is composed of a mosaic board 1, and the mosaic board 1 is composed of a plurality of base color boards 2 and A plurality of pattern boards 3 are combined to form, the bottom surface of the mosaic board 1 is bonded to a glass fiber cloth 4, and the glass fiber cloth 4 is bonded to the honeycomb substrate 10, and the honeycomb substrate 10 is composed of a honeycomb layer 5 and a transition The transition layer 6 is arranged on the back side of the honeycomb layer 5, the honeycomb layer 5 is an aluminum honeycomb panel, and the transition layer 6 is an aluminum plate.

[0033] The manufacturing process is as follows: firstly, the honeycomb layer 5 is stretched and tiled on the transition layer 6, and then compressed and pasted to form the honeycomb substrate 10; acc...

Embodiment 2

[0034] Embodiment two: see Figure 4~7 As shown, a stone honeycomb panel includes a stone panel 9, a honeycomb substrate 10 and a fireproof insulation panel 8, and the three are compositely bonded to form an integrated structure. The stone panel 9 is composed of a carved board 7, and the carved board 7 and the The honeycomb substrate 10 is bonded, and the honeycomb substrate 10 is composed of a honeycomb layer 5 and a transition layer 6. The transition layer 6 is respectively arranged on the upper and lower sides of the honeycomb layer 5, and the honeycomb layer 5 is a plastic honeycomb panel. The transition layer 6 is a galvanized sheet, and the fireproof and thermal insulation board 8 is a rock wool board, which is bonded to the bottom of the honeycomb substrate 10 .

[0035] The manufacturing process is as follows: firstly, the honeycomb layer 5 is stretched and tiled on the transition layer 6, and then pressed and pasted to form a honeycomb substrate 10; Substrate 10 (suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com