Method for reinforcing web members of reinforced concrete truss

A reinforced concrete and concrete technology, applied in building maintenance, construction, building construction, etc., can solve the problems of inconvenient concrete repair and the inability to ensure the compactness of newly poured concrete, and achieve the effect of ensuring compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

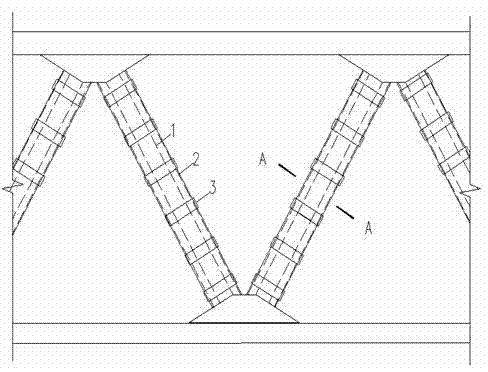

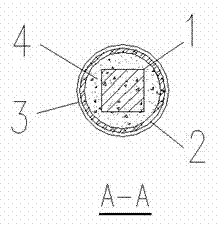

[0013] The method for strengthening the reinforced concrete truss webs of the present invention: firstly, the damaged concrete of the reinforced concrete truss webs 1 is cleaned, and the corroded steel bars are derusted and rust inhibitors are applied, and then the concrete truss webs 1 are fitted with PVC pipe 2 with a slender mouth, and use wooden boards to temporarily block the opening, then pour resin concrete into the PVC pipe, and use CFRP (carbon fiber cloth) or steel plate hoop 3 to tighten the PVC pipe 2, so that the inside of the PVC pipe The poured resin concrete 4 is compacted and overflowed to achieve the purpose of self-extrusion and compaction of the resin concrete 4. After the resin concrete 4 is solidified, the wooden board temporarily blocked at the opening can be removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com