Method for predicting primary capacity of compact carbonate rock gas bearing formations

A productivity prediction and carbonate rock technology, which is applied in the field of logging data interpretation and evaluation, can solve problems such as affecting gas layers, lack of logging data, and predicting the initial stable productivity of gas layers, achieving strong field practicability and simple calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

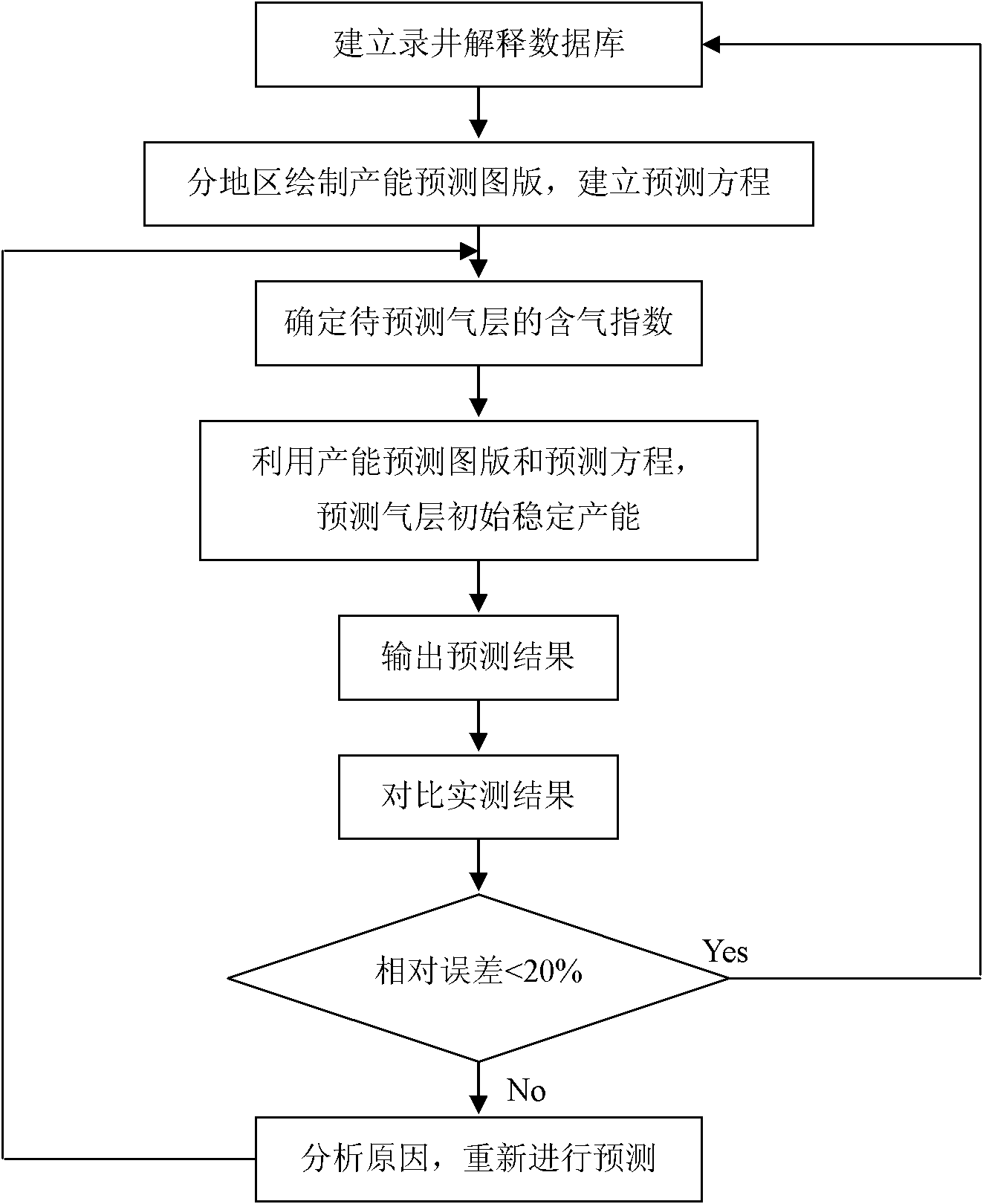

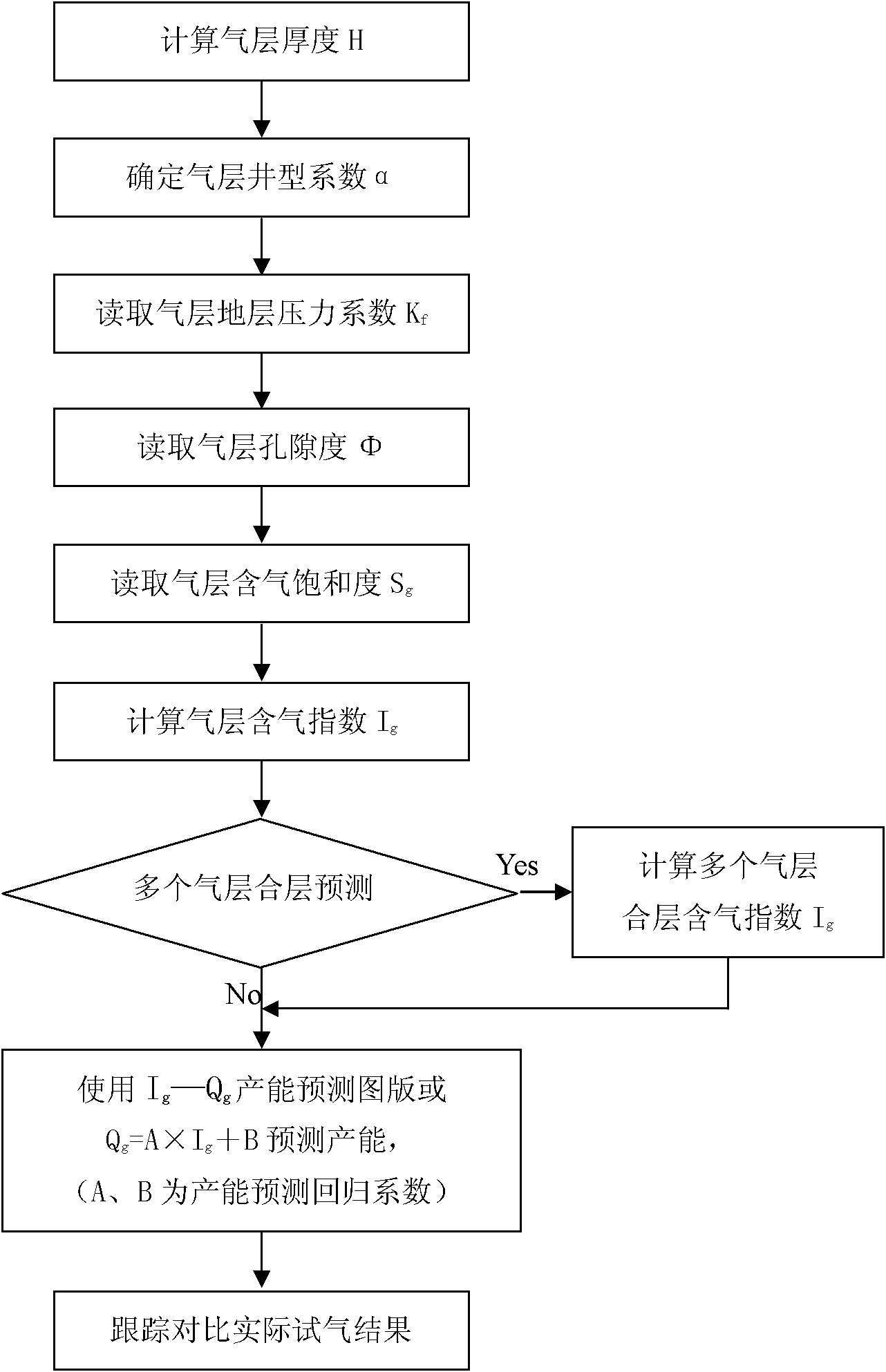

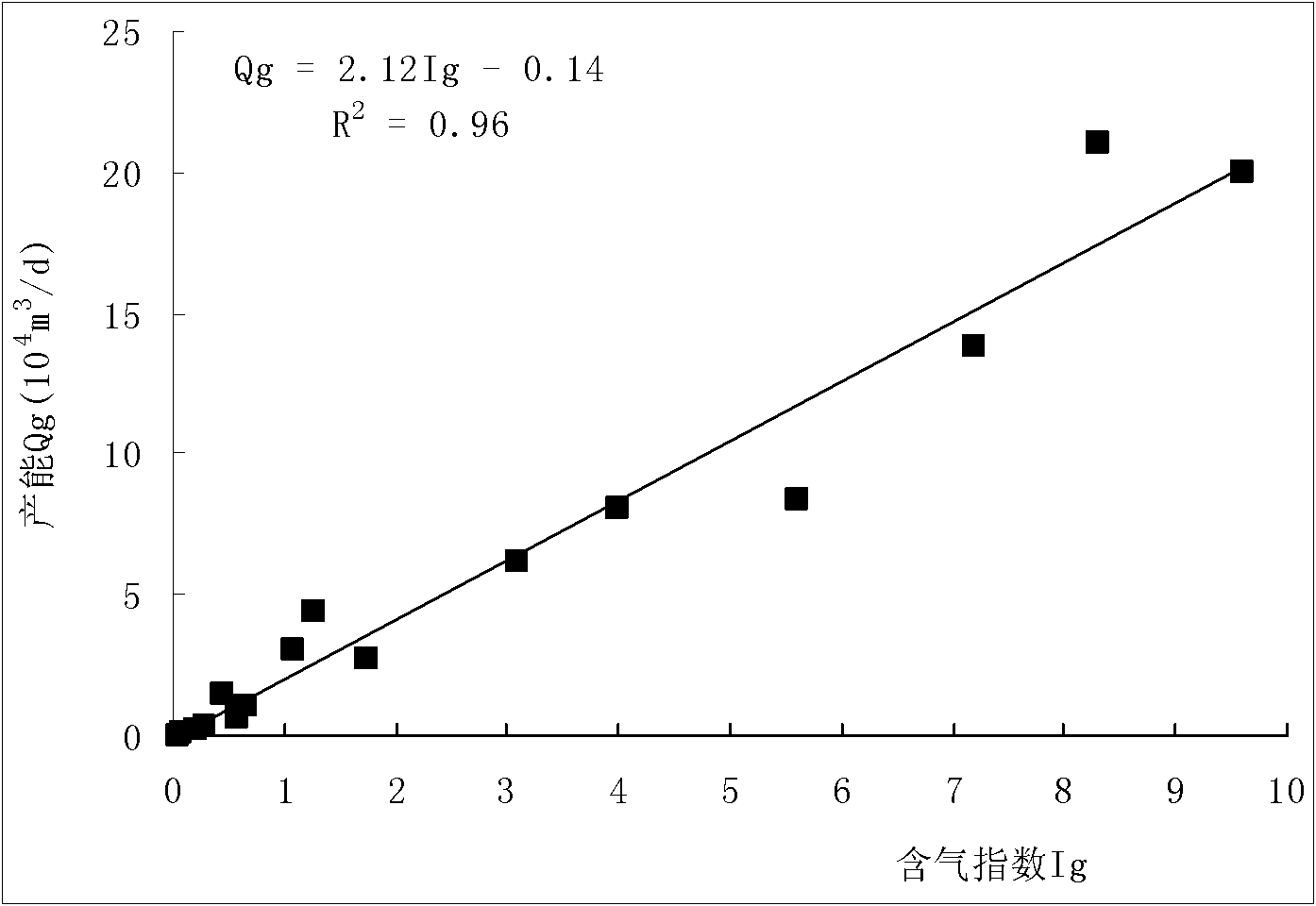

[0021] refer to figure 1 Concrete steps of the present invention are to set up the mud logging interpretation database in the carbonate gas layer area, utilize the database data, use the gas layer gas index Ig and the gas layer gas layer gas index Ig and gas layer that are similar in the same type or reservoir characteristics in the same area and have been confirmed by gas testing The initial stable production capacity Qg is characterized by a linear correlation on the scatter diagram, and the Ig-Qg production capacity prediction chart is made; the Qg=A×Ig+B production capacity prediction equation is established, and the coefficient R 2 It should be greater than 0.5; use the database data to draw Ig-Qg production capacity prediction charts by region and establish the Qg=A×Ig+B production capacity prediction equation to predict the initial stable production capacity in rock and gas layer areas, output the predicted results, and compare them with the measured results. If the err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com