Direct-reading and testing integrated machine for downhole parameters of vertical well and horizontal well of oil field

An all-in-one machine and horizontal well technology, applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve the problems of higher and higher testing efficiency, low working efficiency, and inability to adapt, so as to reduce testing cost and labor intensity, reduce the number of construction workers, and reduce the effect of operating risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

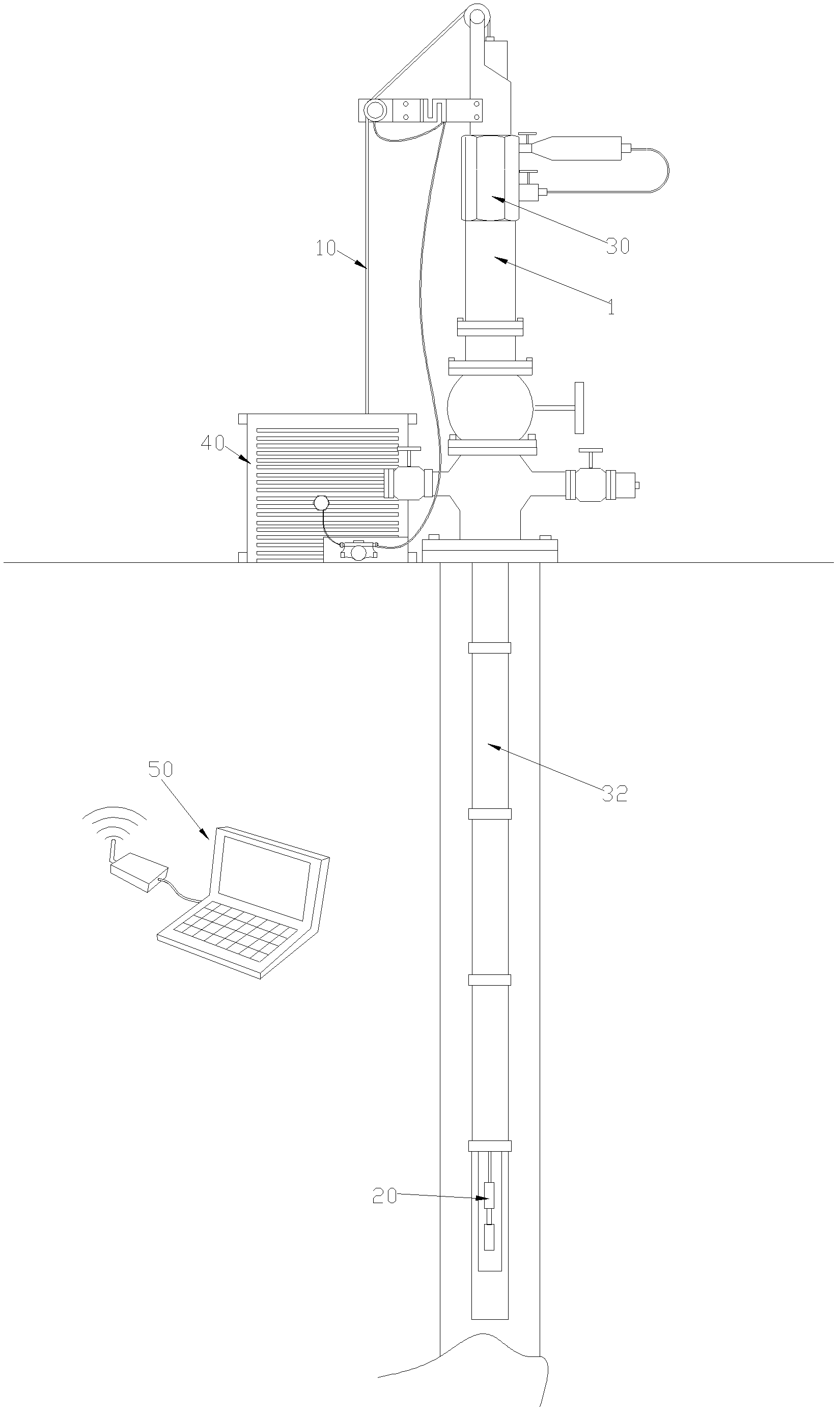

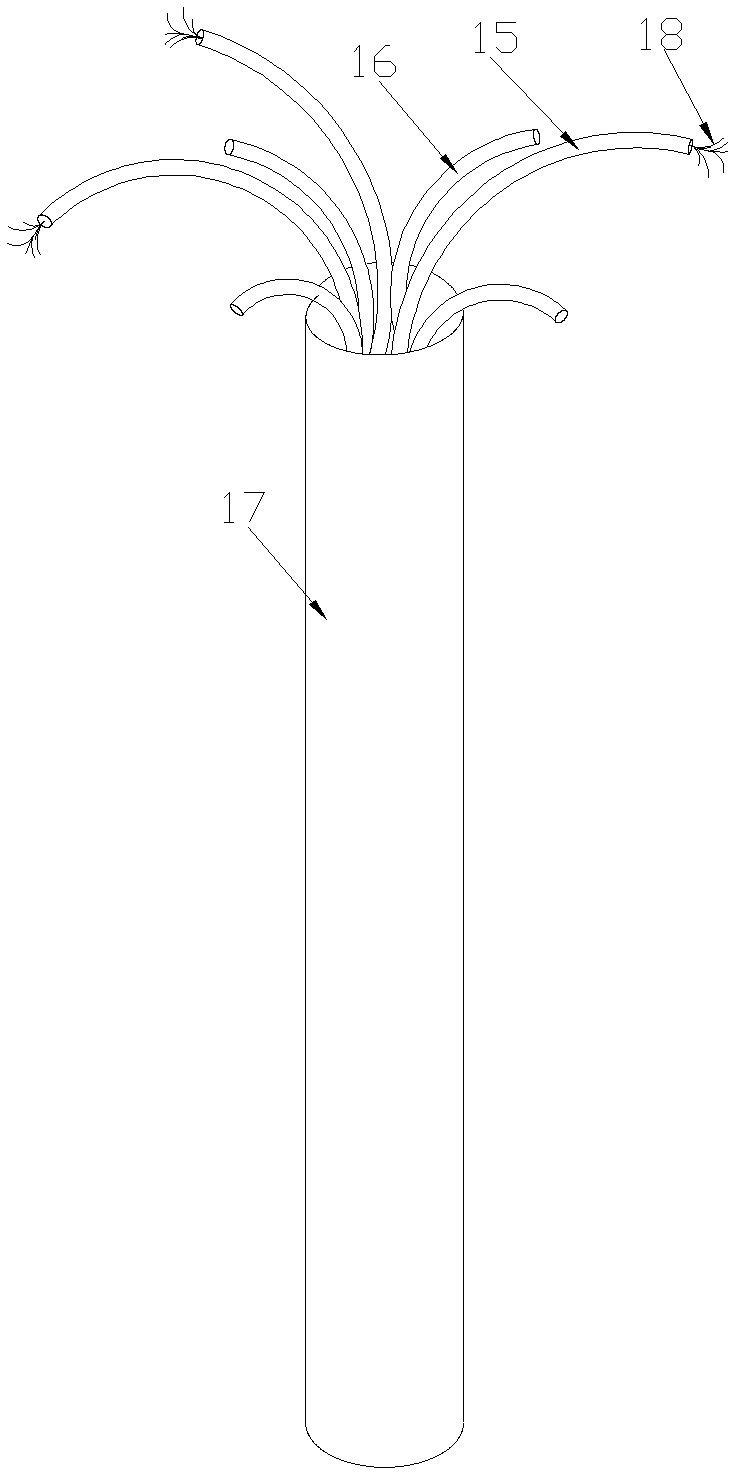

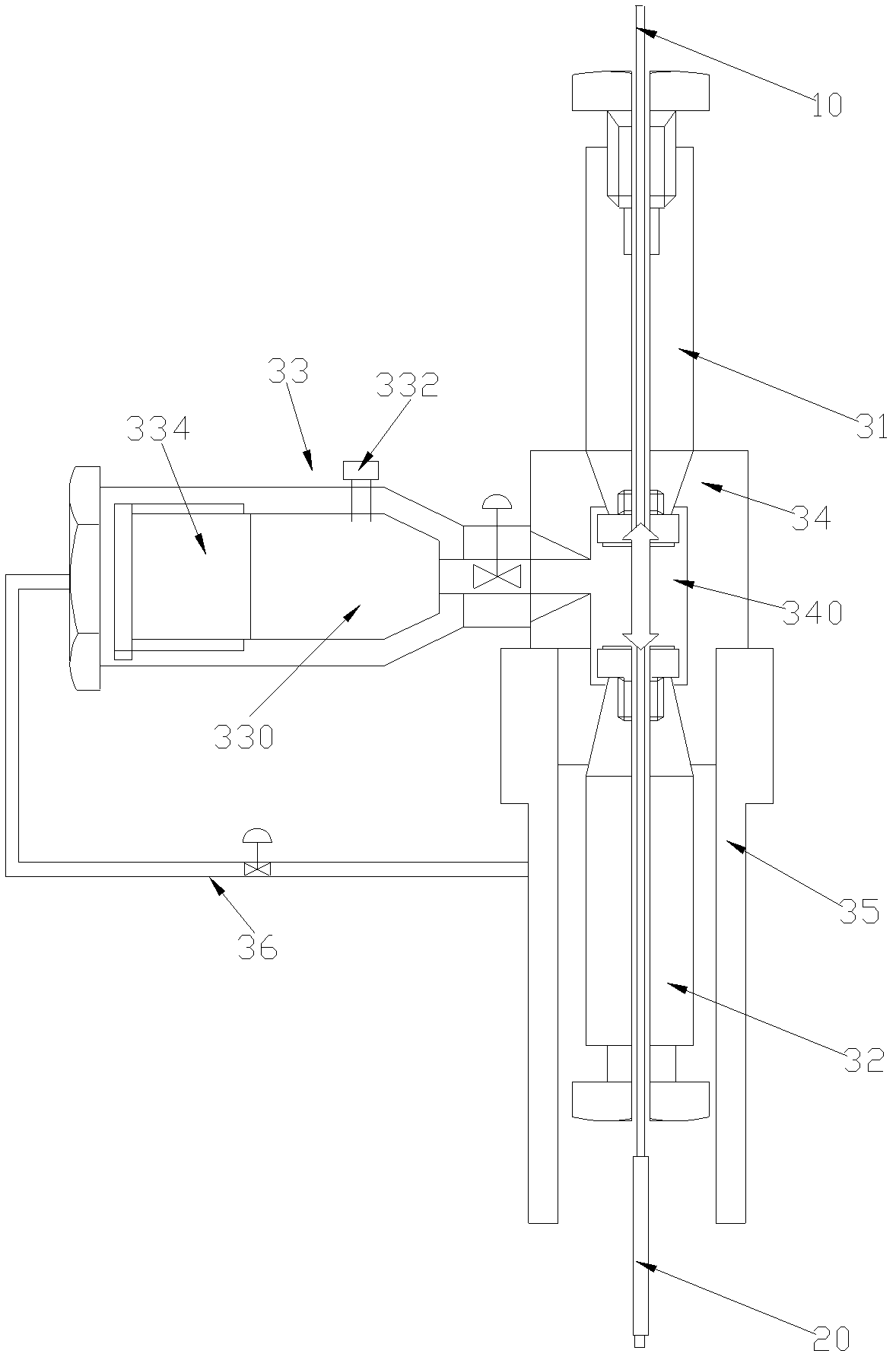

[0026] Example: such as Figure 1-8 As shown, it is an embodiment of an all-in-one machine for direct reading and testing of downhole parameters used in vertical wells and horizontal wells of the present invention. 10 connected to the micro-power consumption collector 20, the tubing crawler that pulls the micro-power consumption collector 20 through the horizontal pipeline, the snubbing operation back pressure wellhead dynamic sealing device 30 installed above the wellhead Christmas tree 1, and the snubbing operation back pressure wellhead dynamic sealing device 30 The well crimping pipe 35 under the pressure-type wellhead dynamic sealing device 30 , the self-control winch 40 connected to the other end of the fiber cable 10 and located on the ground, and the wireless processing device 50 for wireless remote control of the self-control drawwork 40 . Similarly, the self-controlled winch can also be controlled in a wired manner, which can also achieve the purpose of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com