Hydraulic system for steel collection device

A collection device and hydraulic system technology, which is applied to fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of inaccurate control of steel collection, complex hydraulic system structure, and low degree of automation. Achieve the effect of realizing production automation, high control precision and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

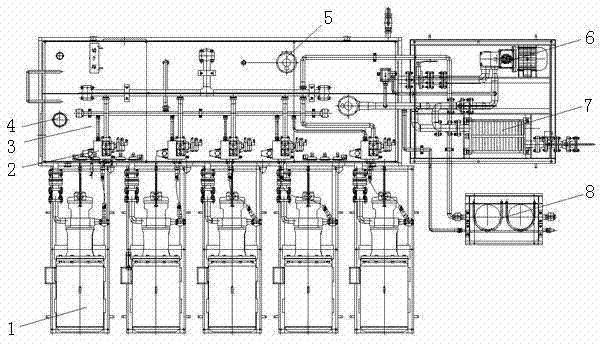

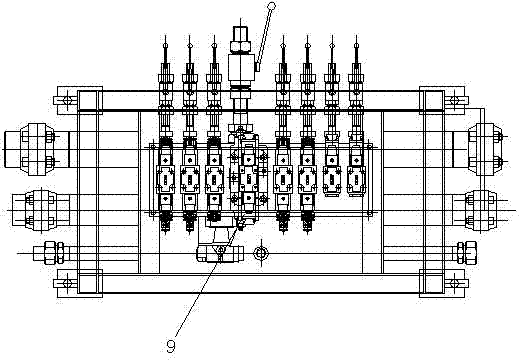

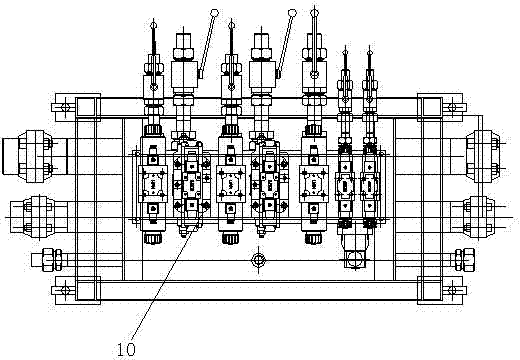

[0015] like Figure 1-5 As shown, the present invention includes a hydraulic station, an accumulator group 8, and a control valve station one 9 connected to the hydraulic station, a control valve station two 10, a control valve station three 11, and a control valve station four 12. The hydraulic station mainly It consists of a plunger pump unit 1 and an oil tank assembly 3, the plunger pump unit 1 is connected to the oil tank assembly 3 through a pressure regulating valve group 2, the oil tank assembly 3 is connected to the accumulator group 8, and the The accumulator group 8 is composed of two groups of accumulators connected to the control valve group. The oil tank assembly 3 is also connected with an air filter 4, an oil return filter 5, a circulating cooling pump group 6, and a plate heat exchanger. 7, the control valve table one 9 is composed of a cooling bed lifting circuit, a baffle lifting circuit, and a cutting blade replacement circuit, and the control valve table tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com