Burning control system of fuel oil burner

A control system and burner technology, which is applied to burners, control combustion, lighting and heating equipment, etc., can solve the problems of low accuracy of mechanical adjustment of oil and gas ratio, low fuel adjustment ratio of burners, and high requirements for oil pump pressure to improve efficiency. , The effect of reducing exhaust emissions and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the content of the present invention more obvious and understandable, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

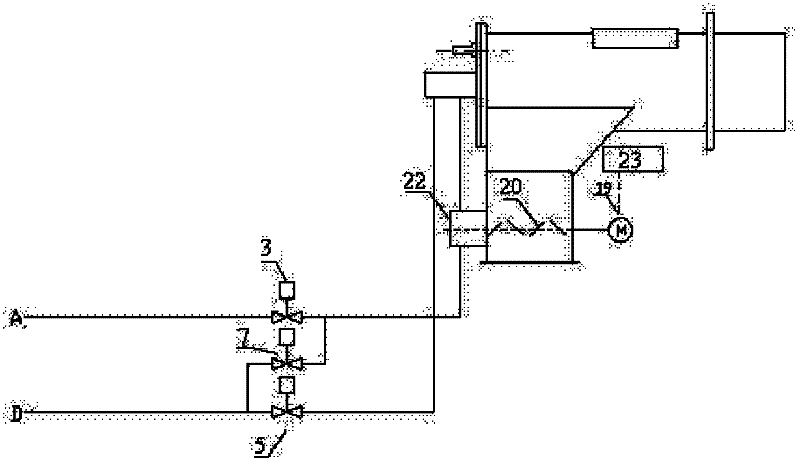

[0032] combine figure 1 Shown is the oil burner control system in the prior art, which controls the operation of the damper driver 19 (servo motor) through the temperature control system 23 during application, and then the damper 20 is driven by the linkage to move, and at the same time drives the oil quantity regulating valve 22 to open To adjust the size of the fire, the system realizes the action control of the oil inlet valve 3, the medium circulation valve 5, the purge valve 7 and the temperature control system 23 through the solidified program controller, and the adjustability is poor.

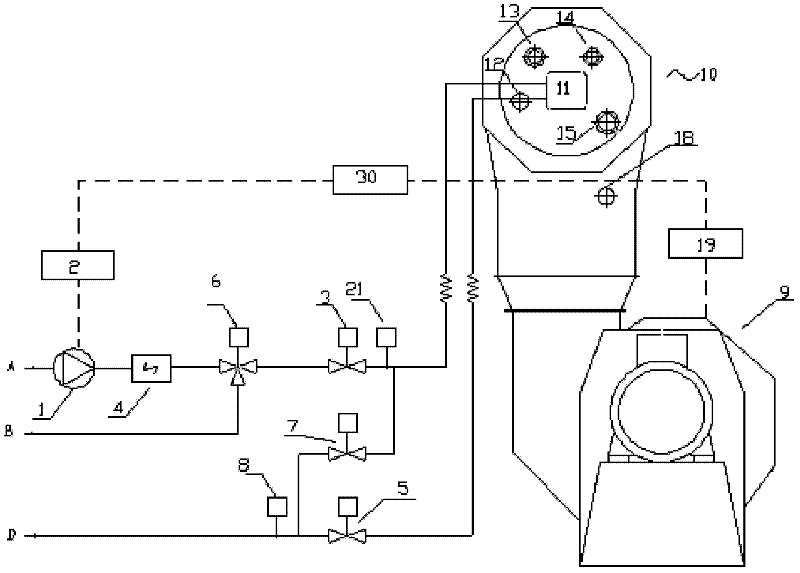

[0033] combine figure 2 As shown, the present invention includes an oil delivery channel A, an atomized medium channel D, an ignition device 10, a wind pressure sensor 18, a fan dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com