Safe evacuation system for airflow closed channel on side of building element

A closed channel and building component technology, applied in the field of personnel escape system, can solve the problems of increasing initial investment funds, manufacturing difficulty and operating costs, low smoke outlet speed, and inability to remove smoke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

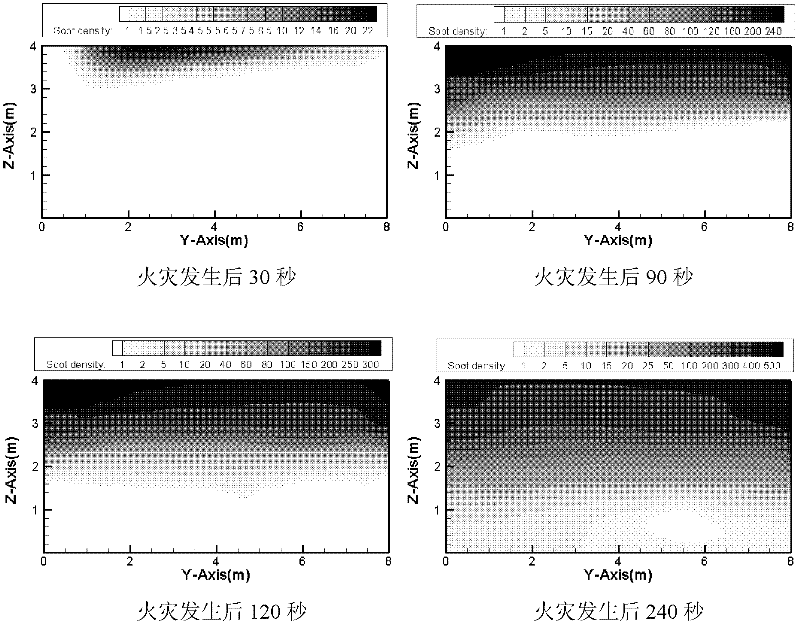

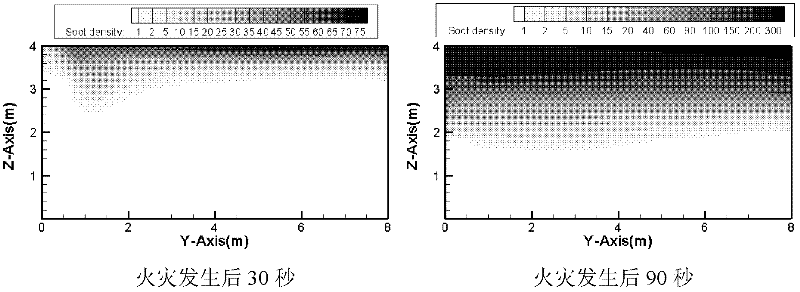

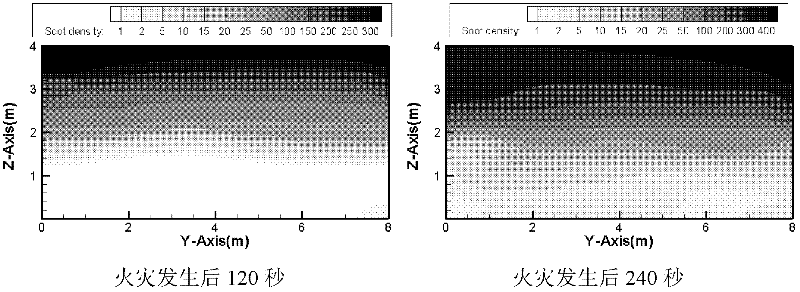

Image

Examples

specific Embodiment

[0065] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

[0066] Comply with the above technical scheme, as shown in Figure 1 and figure 2 shown. Firstly, the ratio of the area at the entrance of the second nozzle to the area at the exit is 1:5. The air speed ratio is 5:1. Because the air supply speed is directly proportional to the nozzle area. This makes it possible to meet the above requirements when the area of the inlet of the second nozzle is equal to that of the inlet of the first nozzle (the areas of the outlet and inlet of the first nozzle are equal). Then when the area of the first nozzle is 30m×0.1m, the area of the second nozzle is 30m×0.5m. The size of the first sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com