Ground source heat pump system for force seepage

A ground source heat pump and geothermal technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve the problems of high operating costs, large temperature fluctuations of intermediate water, and lower temperature on the buried pipe side, achieving low operating costs and small initial investment. , the effect of unstable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

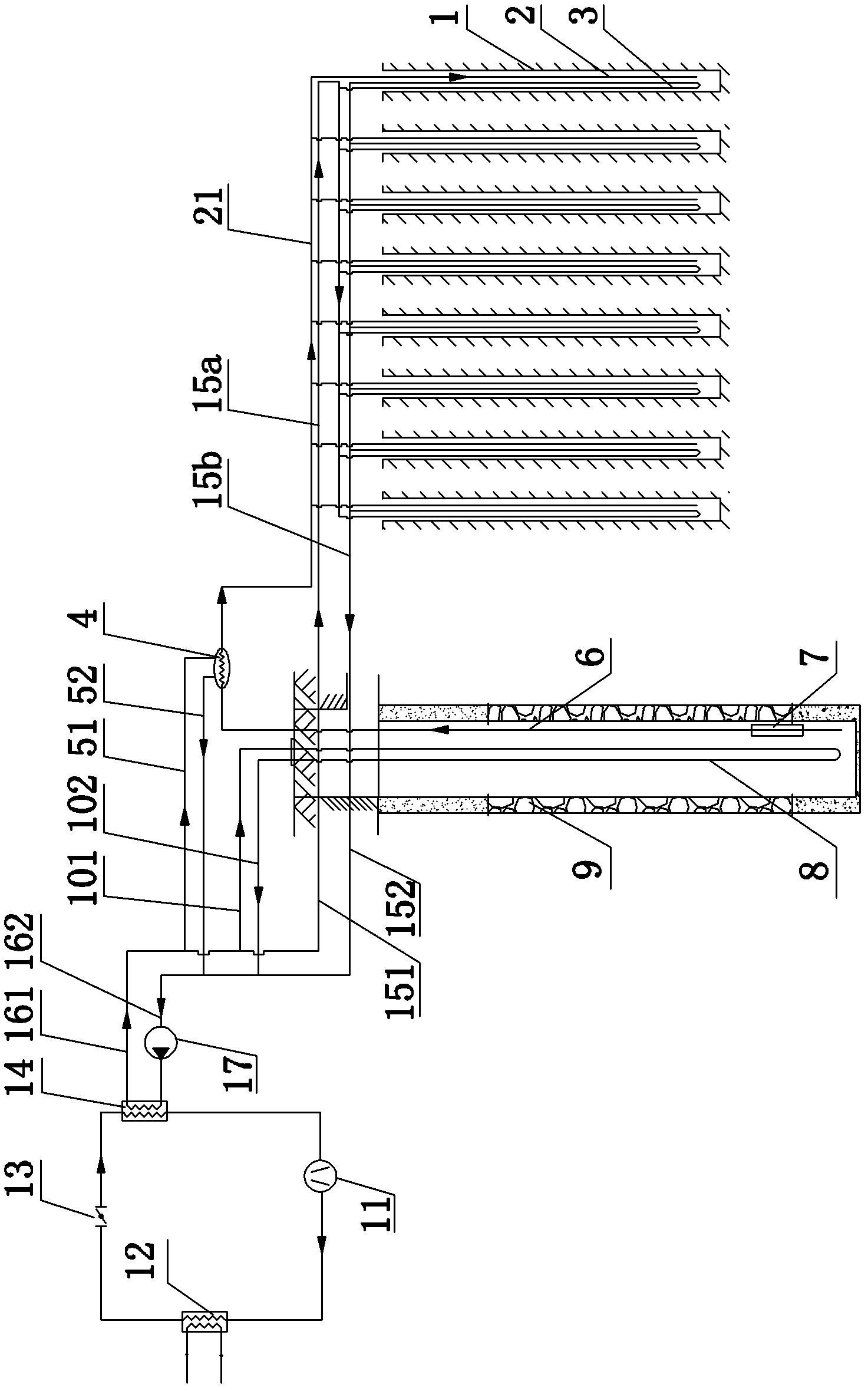

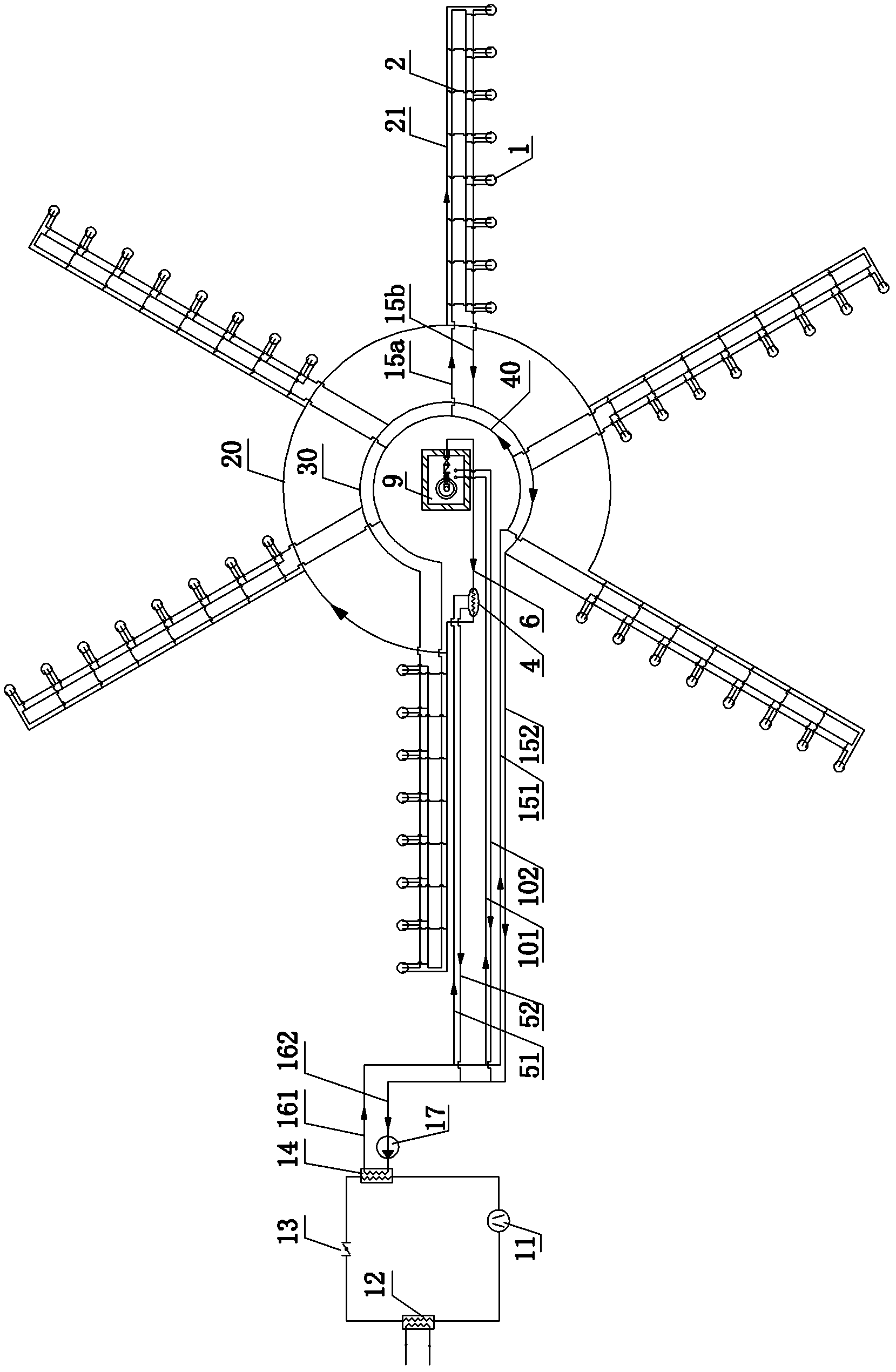

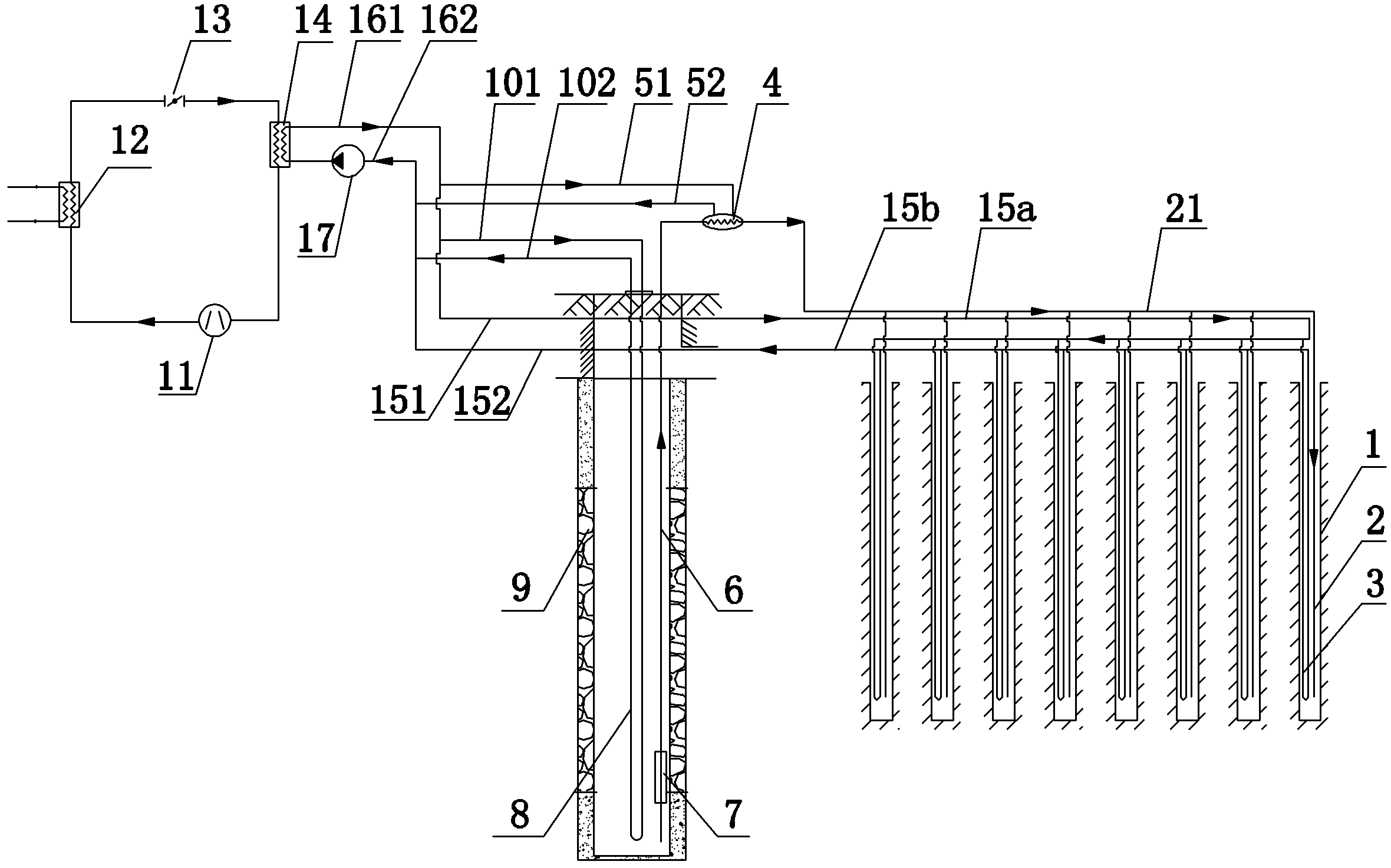

[0028] like figure 1 and figure 2 Commonly shown is a specific implementation of the forced seepage ground source heat pump system of the present invention, including: a refrigerant subsystem for cooling / heating the user subsystem, the refrigerant subsystem includes sequentially connected into a cycle The compressor 11 of the circuit, the condenser 12, the expansion valve 13 and the evaporator 14, its structure and working principle belong to the well-known technology in this field, no longer describe in detail here; Thermal geothermal heat exchange subsystem.

[0029] The geothermal heat exchange subsystem is provided with a heat exchange medium main supply pipe 161 and a heat exchange medium main return pipe 162 , and a circulation pump 17 is arranged on the heat exchange medium main return pipe 162 . The geothermal heat exchange subsystem also includes the following three loops:

[0030] An underground well water heat exchange circulation loop, the underground well wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com