System for monitoring fire facing side wall temperature of water cooled wall of power station boiler on line, and monitoring method

A monitoring system, a technology for power station boilers, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of inability to adapt to high temperature, corrosion, dust, and low accuracy, so as to reduce operating costs, reduce accident rates, and avoid pipe bursts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides an online monitoring system and method for monitoring the temperature of the water-cooled wall of a power plant boiler facing the fire side wall. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

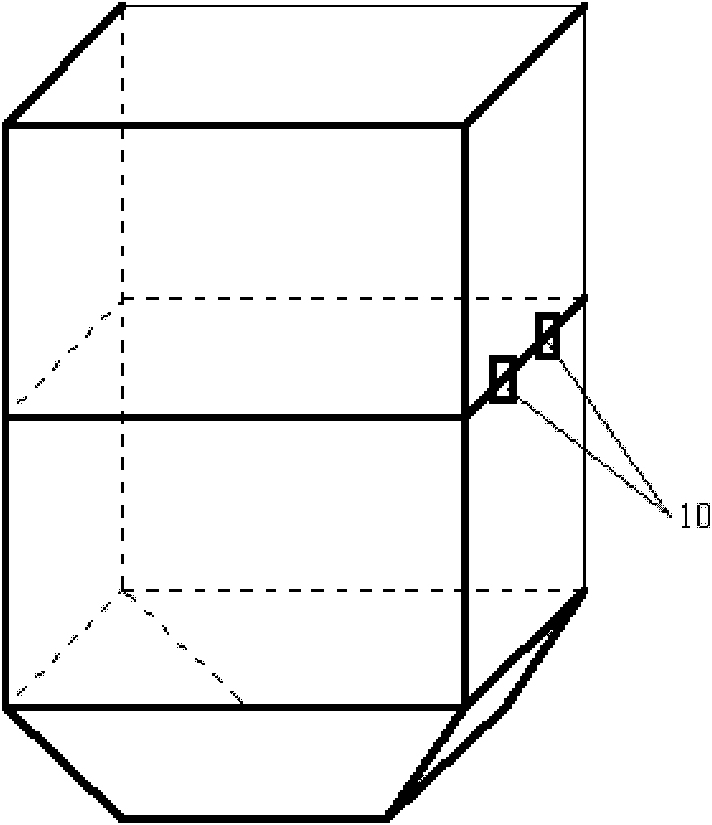

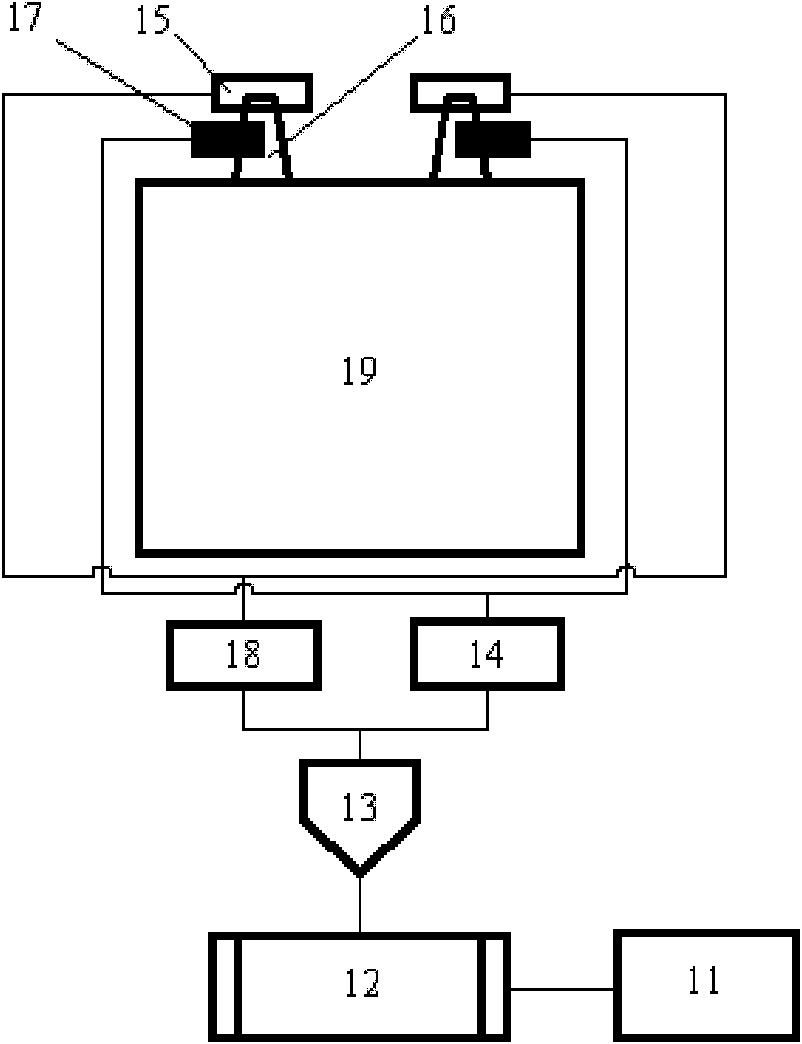

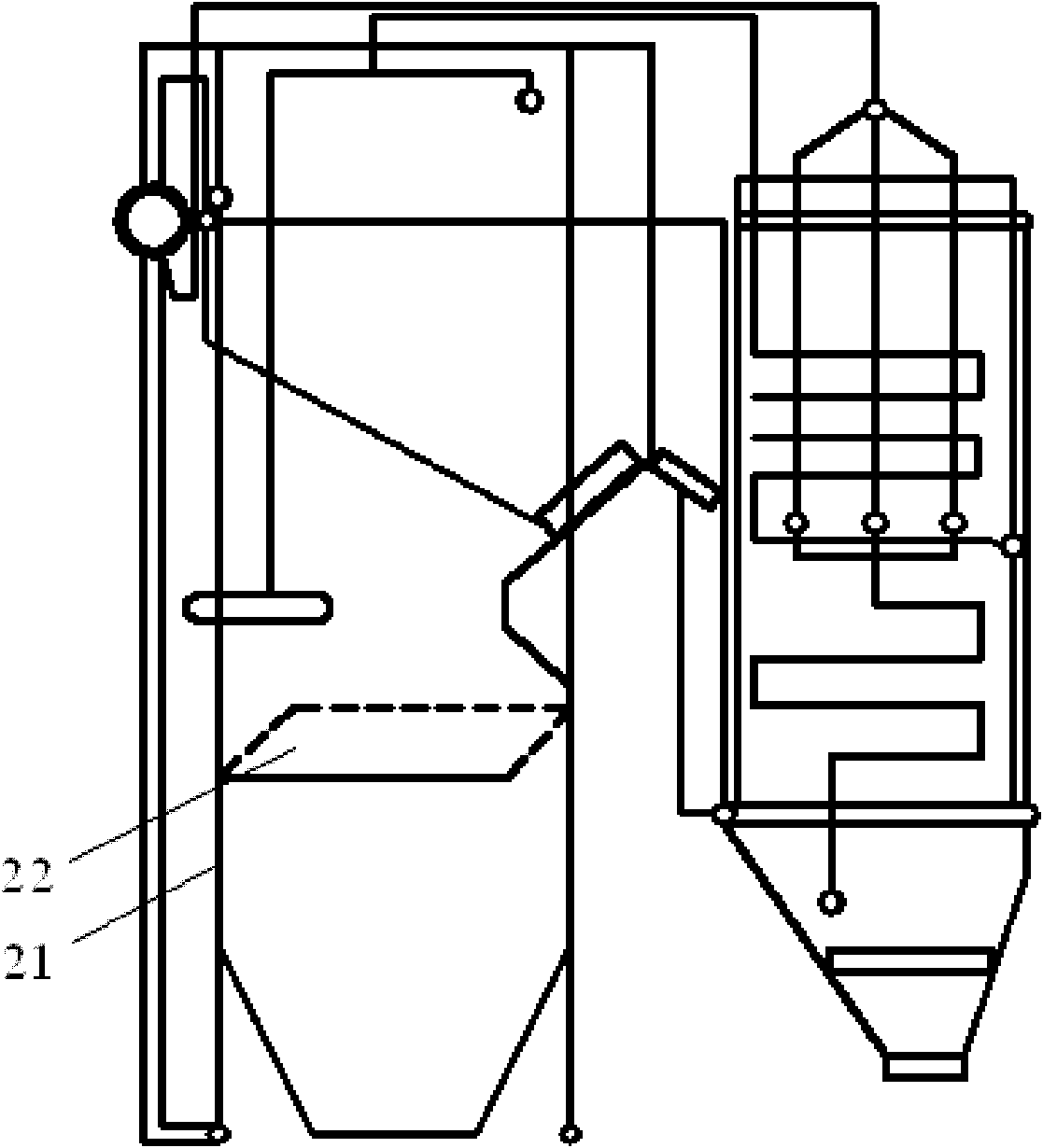

[0021] Figure 1a with Figure 1b It is the wall temperature monitoring system diagram of the water wall. Two groups of acoustic wave transceivers 10 composed of acoustic waveguide 16, electric loudspeaker 15 and electret microphone 17 are arranged on the same level of the water-cooled wall on one side of the furnace to the heating surface on the fire side. The electric loudspeaker 15 is connected to the power amplifier 14, and the power amplifier 14 is connected to the output end of the junction box 13; the special electret microphone 17 is connected to the signal conditioner 18, and the signal conditioner 18 is connected to the input end of the junction box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com