A Modeling Method for Blast Furnace Hot Stove Lining Erosion Based on Distributed Optical Fiber

A technology of distributed optical fiber and modeling method, applied in the direction of measuring heat, thermometers with physical/chemical changes, measuring devices, etc., can solve the problems of poor measurement stability, high cost, inaccurate results, etc., and achieve good electrical insulation. , temperature measurement stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

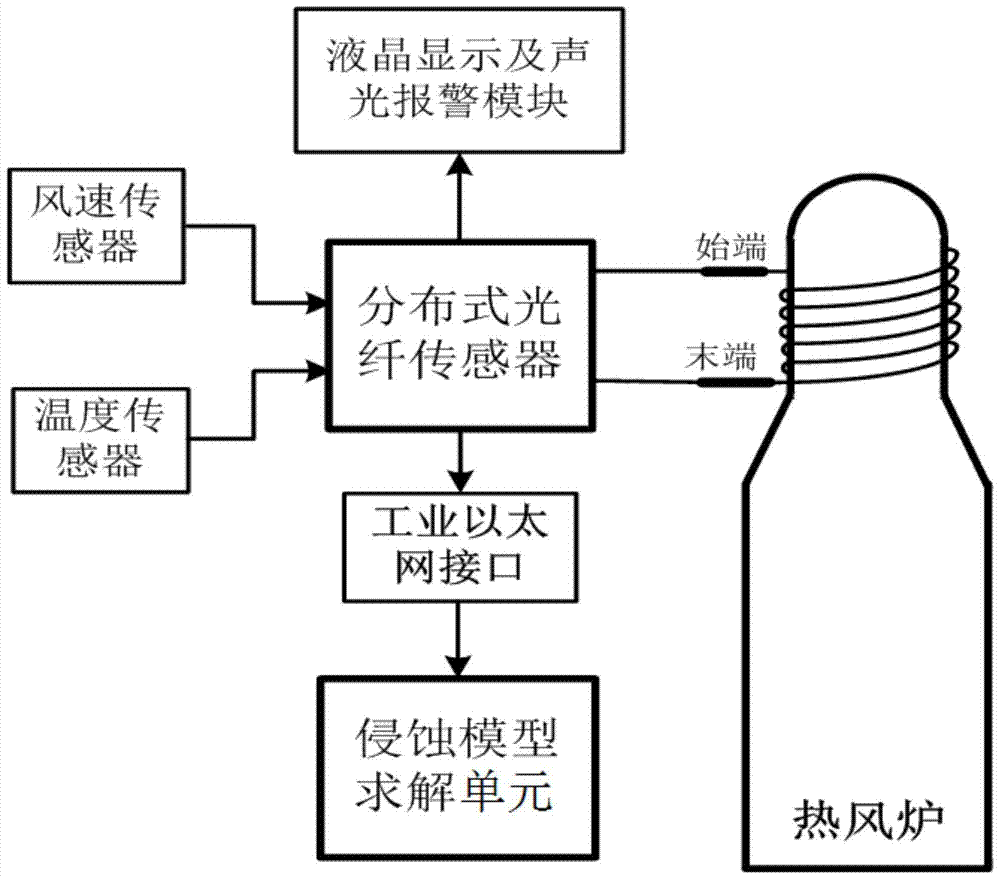

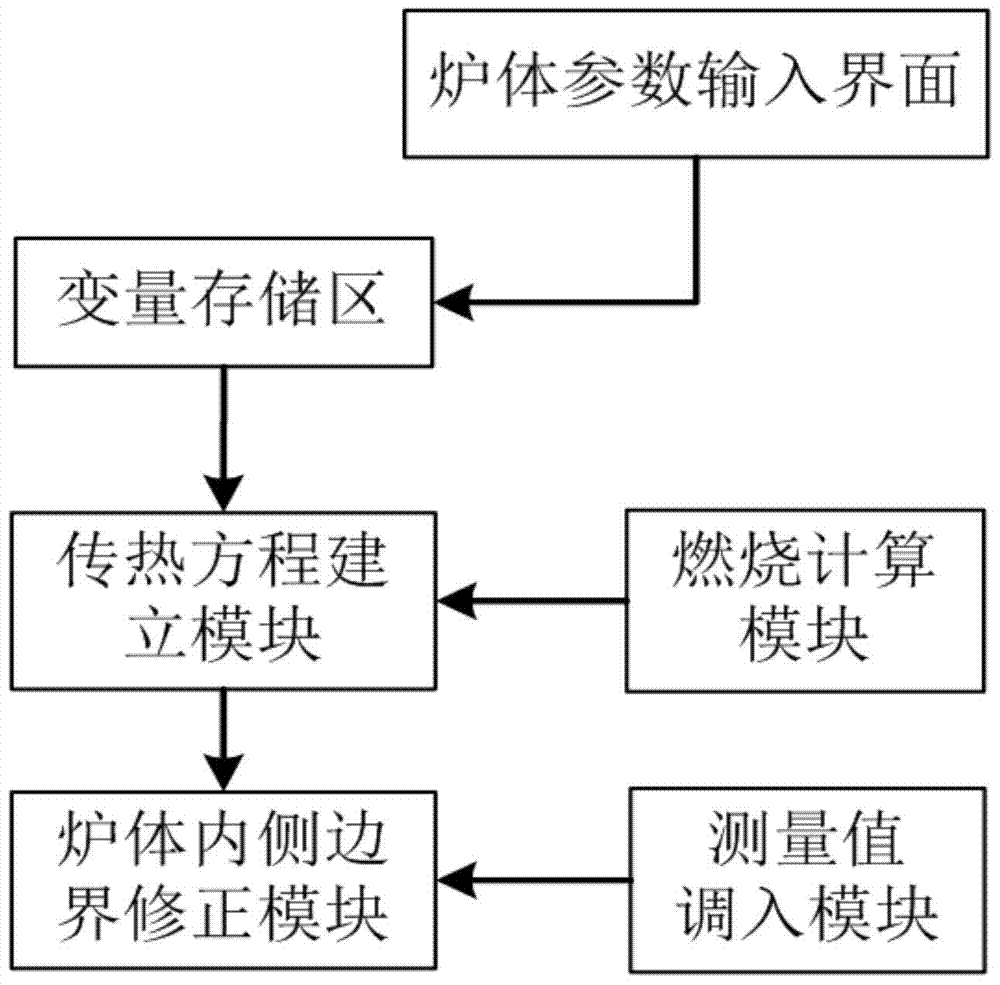

[0063] See figure 1 In this embodiment, based on the shortcoming that the infrared thermal imaging method cannot accurately analyze the condition of the hot blast stove, a distributed optical fiber-based blast furnace hot blast stove lining erosion modeling system and method are proposed to quantify the erosion status of the hot blast stove lining Forecast to achieve effective monitoring of the thermal state of the hot blast stove body. The application of the hot blast stove erosion model can accurately predict the location of the hot blast stove’s erosion, so that a targeted repair plan can be formulated before the furnace is shut down, so as to improve the repair efficiency and reduce the difficulty of repair. The coke ratio and the improvement of blast furnace productivity are of great significance.

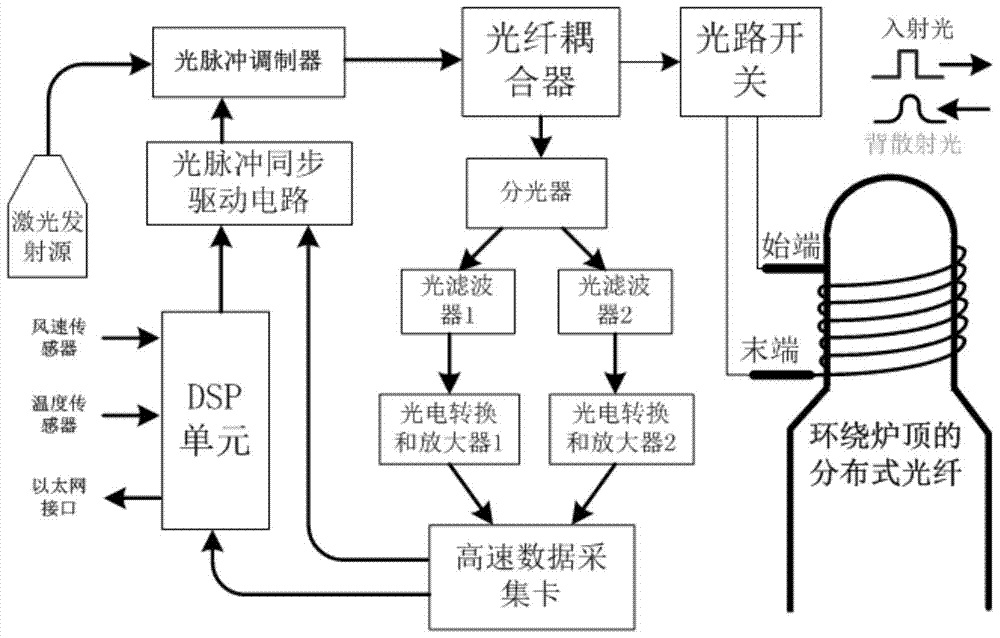

[0064] The erosion modeling system of this embodiment includes an erosion model solution unit, a display and an alarm module (i.e. figure 1 The liquid crystal display and acous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com