Slight abrasion measurement method based on shelter processing technology

A measurement method and a slight technique, applied in the direction of testing wear resistance, etc., can solve the problems of jump depth information, small wear of precision parts, and low precision of results, and achieve the effect of avoiding sample contamination, saving energy, and saving processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A method for measuring slight wear based on masking processing technology, comprising the following steps:

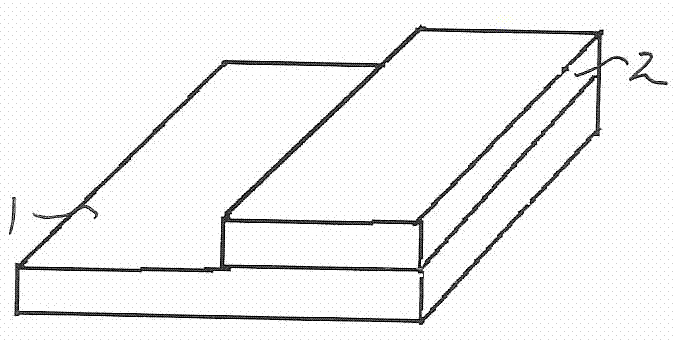

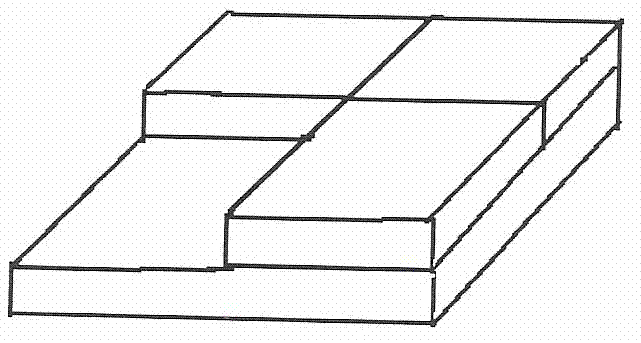

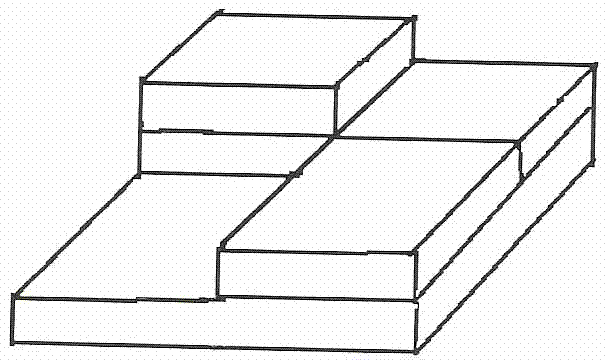

[0033] (1) Put the large and small samples 1 and 2 into the vacuum processing chamber, place the small sample on part of the surface of the large sample for masking, and then carry out surface treatment on the large and small samples to form a treated area and an untreated area on the surface of the large sample, Then remove the small sample;

[0034] (2) Take out the large and small samples from the vacuum treatment chamber, and use a pin-on-disk abrasion machine or a reciprocating abrasion machine to conduct wear experiments on the untreated and treated areas formed on the large samples to form wear marks;

[0035] (3) Use an interference microscope to measure, and transmit the measurement data to a digital camera or computer; use the reciprocal of the maximum relative movement d of the wear-scar interference fringe to measure the wear resistance of each area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com