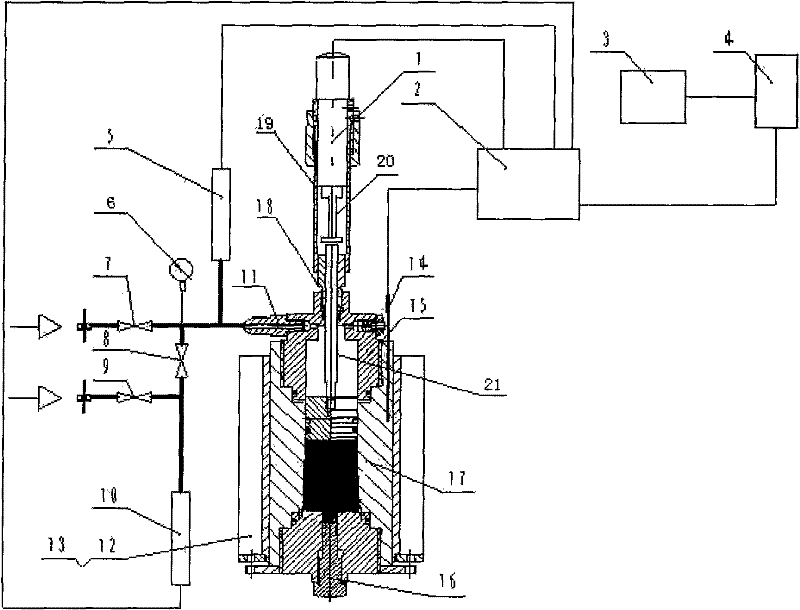

Temperature increasing and pressurizing foam cement slurry density testing device

A technology of heating, pressurizing, and testing devices, which is applied in measurement devices, specific gravity measurement, instruments, etc., can solve the problems of low density, difficult design and construction of cementing engineering, and low permeability, and achieve the effect of accurate measurement values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Example 1 Picture 8 As shown, the initial foam cement slurry density is 0.99g / cm 3 , The pressure does not change, the temperature rises from 30 ℃ to 75 ℃ density change graph, can see through this test device, the temperature increases, the density change range of the foam cement slurry is very small.

Embodiment 2

[0073] Example 2 such as Picture 9 As shown, the initial foam cement slurry density is 0.61g / cm 3 , The temperature does not change, and the pressure changes from 0-5000Kpa. It can be seen from this test device that the density of the foam cement slurry increases greatly when the pressure is in the range of 0-2000KPa.

Embodiment 3

[0074] Example 3 such as Picture 10 As shown, the initial foam cement slurry density is 0.95g / cm 3 , The change of foam cement slurry density when temperature and pressure change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com