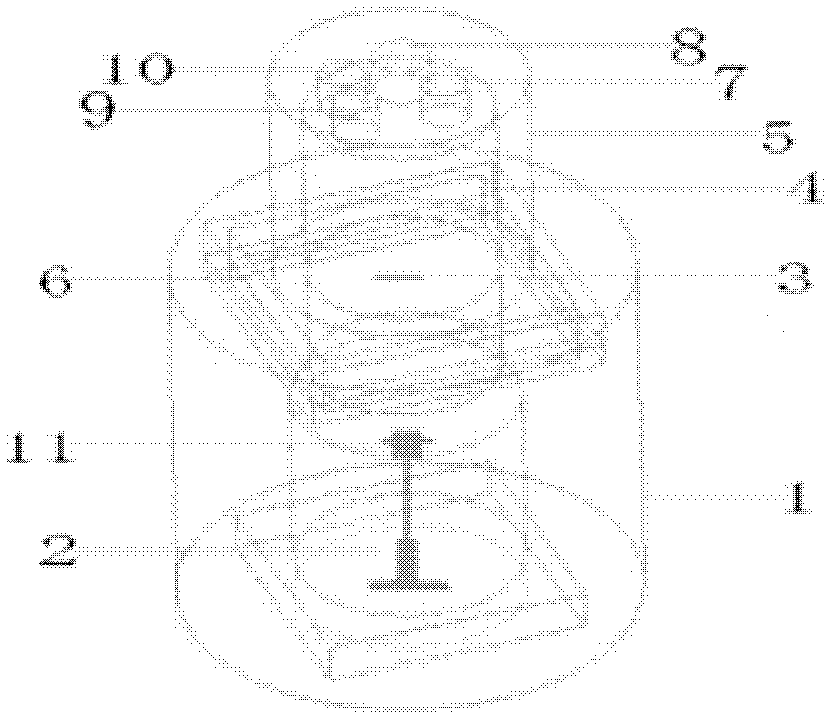

Embedded type magnetic stirring device

A magnetic stirring device and magnetic stirring technology are applied in the directions of dissolution, mixer, chemical instrument and method, etc., which can solve the problems of poor reproducibility, easy change of the relative position of the stirring device, insufficient stirring, etc., to eliminate influence and save energy. To clean the magnetic stirring bar, the effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

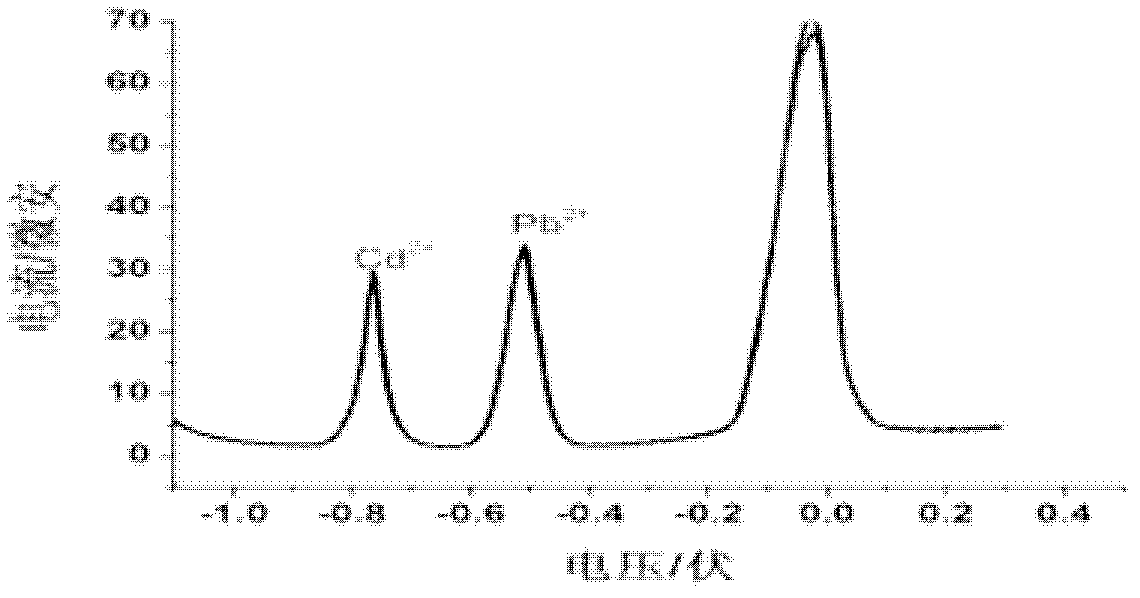

[0018] Embodiment 1 adopts embedded magnetic stirring device of the present invention for heavy metal ion Pb 2+ and Cd 2+ Measurement reproducibility check

[0019] The bottom solution of the electrolytic cell is a buffer solution of 0.1M sodium acetate and acetic acid (pH=4), and the substance to be tested is Pb 2+ and Cd 2+ solution, the concentration is 20ppb, the working electrode is a glassy carbon electrode coated with bismuth in situ, the reference electrode is silver / silver chloride, and the counter electrode is a platinum wire electrode. Using differential pulse stripping voltammetry, the potential increment is 0.005V, the amplitude is 0.08V, the pulse width is 0.01s, and the deposition is under stirring conditions for 120s. The experiment is repeated twice, and after each test is completed, at +0.3V potential The electrodes were cleaned for 30 s, and the reproducibility of the measurement results of the two experiments was compared. Depend on image 3 It can be ...

Embodiment 2

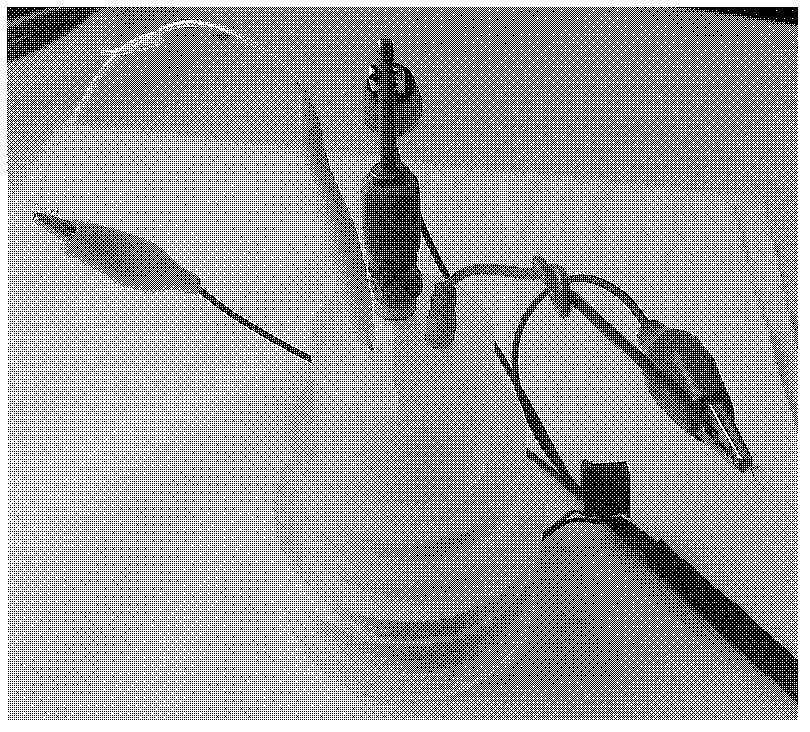

[0020] Embodiment 2 The test of the stirring function of the embedded magnetic stirring device of the present invention

[0021] The bottom solution of the electrolytic cell is a buffer solution of 0.1M sodium acetate and acetic acid (pH=4), and the substance to be tested is Pb 2+ and Cd 2+ solution, the working electrode is a glassy carbon electrode coated with bismuth in situ, the reference electrode is silver / silver chloride, and the counter electrode is a platinum wire electrode. Using differential pulse stripping voltammetry, the potential increment is 0.005V, the amplitude is 0.08V, and the pulse width is 0.01s. The deposition is 120s under stirring and non-stirring conditions respectively. After each test is completed, the electrode is cleaned at a potential of +0.3V 30s, investigated the heavy metal ion Pb under unstirred and stirred conditions 2+ and Cd 2+ stripping voltammetric response. Depend on Figure 4 (Pb 2+ and Cd 2+ The concentration is 20ppb) and Fi...

Embodiment 3

[0022] Embodiment 3 adopts embedded magnetic stirring device of the present invention for heavy metal ion Pb 2+ and Cd 2+ Electrochemical determination of

[0023] The bottom solution of the electrolytic cell is a buffer solution of 0.1M sodium acetate and acetic acid (pH=4), and the substance to be tested is Pb 2+ and Cd 2+ , the working electrode is a glassy carbon electrode coated with bismuth in situ, the reference electrode is silver / silver chloride, and the counter electrode is a platinum wire electrode. Using differential pulse stripping voltammetry, the potential increment is 0.005V, the amplitude is 0.08V, the pulse width is 0.01s, the test concentration is 5ppb, 10ppb, 20ppb, 40ppb, 60ppb, 80ppb and 100ppb, deposited under stirring conditions for 120s, After each test is completed, the electrode is cleaned at the potential of +0.3V for 30s, and the test of the next concentration is continued, and the heavy metal ion Pb at different concentrations is investigated. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com