Magnetism in-situ detection method for metal cracking expansion under condition of variable magnetic excitation

A crack propagation and metal technology, applied in the direction of material magnetic variables, can solve the problems of reliability impact of magnetic memory detection technology, difficulty in detection, time-consuming and labor-intensive, etc., to improve detection efficiency and accuracy, reduce detection errors, and reduce time consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

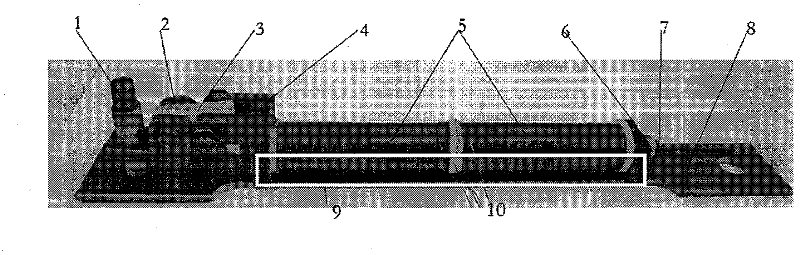

[0046] In the embodiment, the 16MnR material commonly used in the pressure vessel is selected to make the tensile test piece. The effective width of the test piece is 26mm, and the thickness of the test piece is 4mm. A 5mm×1mm macroscopic crack defect is prefabricated in the center of the test piece. main structure size Figure 5 shown.

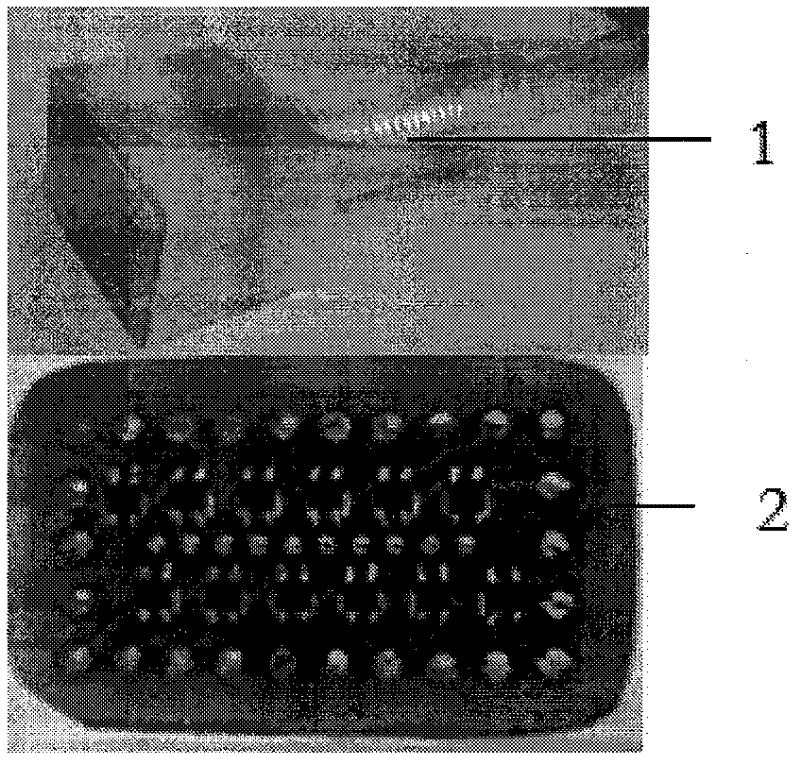

[0047] In this embodiment, the magnetic sensor adopts the GaS high-sensitivity Hall sensor developed by the Institute of Semiconductors, Chinese Academy of Sciences. Its dimensions are 1.5mm×1.7mm, the sensitivity is 10mv / mA.KGs, the linearity is 0.1%, and the working temperature is - 40℃~+125℃; the input resistance is 0.67KΩ, and the output resistance is 0.96KΩ.

[0048] The exciting device in this embodiment is composed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com