Flat-top light beam shaping control method for achieving abrupt edge and low light-intensity variation and shaping device thereof

A light intensity fluctuation and flat-top beam technology, which is applied in optics, optical components, instruments, etc., can solve the problems of large fluctuations in the flat-top light intensity of the beam, the inability to achieve arbitrary setting positions in the far field, and the edge of the shaped beam is not steep, etc. , to achieve the effect of low light intensity fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

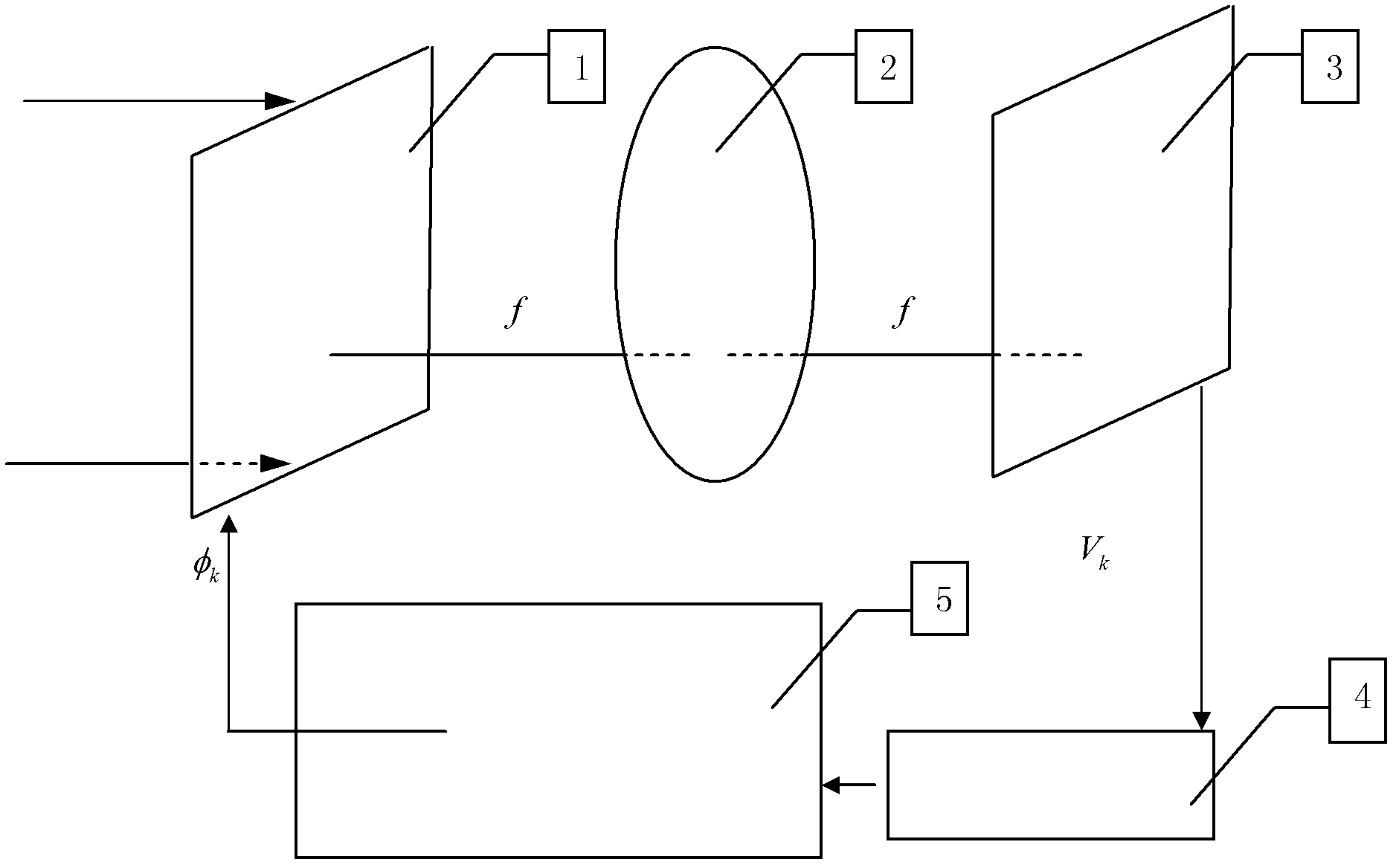

[0026] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 1. A flat-hat beam shaping device with steep edges and low fluctuations in light intensity, which includes an optical phased array 1, a lens 2, an output surface 3, an intensity analysis acquisition module 4 and a processor module 5, and a lens 2 Located between the surface where the optical phased array 1 is located and the output surface 3, the distance between the lens 2 and the phased array 1 and the output surface 3 is one times the focal length f, the incident beam passes through the optical phased array 1 and then passes through the lens 2 The Fourier transform is used to shape the light beam, and the shaped light field is obtained at the focal plane position of the lens 2, that is, the output plane 3, and the intensity distribution acquisition module 4 collects the beam intensity distribution of the shaped light field on the output surface 3, and the The collected data is transmitted to the processor module 5, and ...

specific Embodiment approach 2

[0028]Embodiment 2. A method for shaping and controlling a flat-hat beam shaping device with steep edges and low fluctuations in light intensity described in Embodiment 1. It includes the following steps:

[0029] 1. Obtain the initial phase φ according to formula (1) 1 ,

[0030] φ 1 = φ F +2π(rand-0.5) sinc -1 (|A F |) (1)

[0031] φ F For the expected intensity distribution of the beam I T Spatial phase distribution of light field after fast Fourier transform, A F For the expected intensity distribution of the beam I T The spatial amplitude distribution of the light field after fast Fourier transform, rand is a random distribution between 0 and 1, sinc -1 is the inverse function of the sinc function;

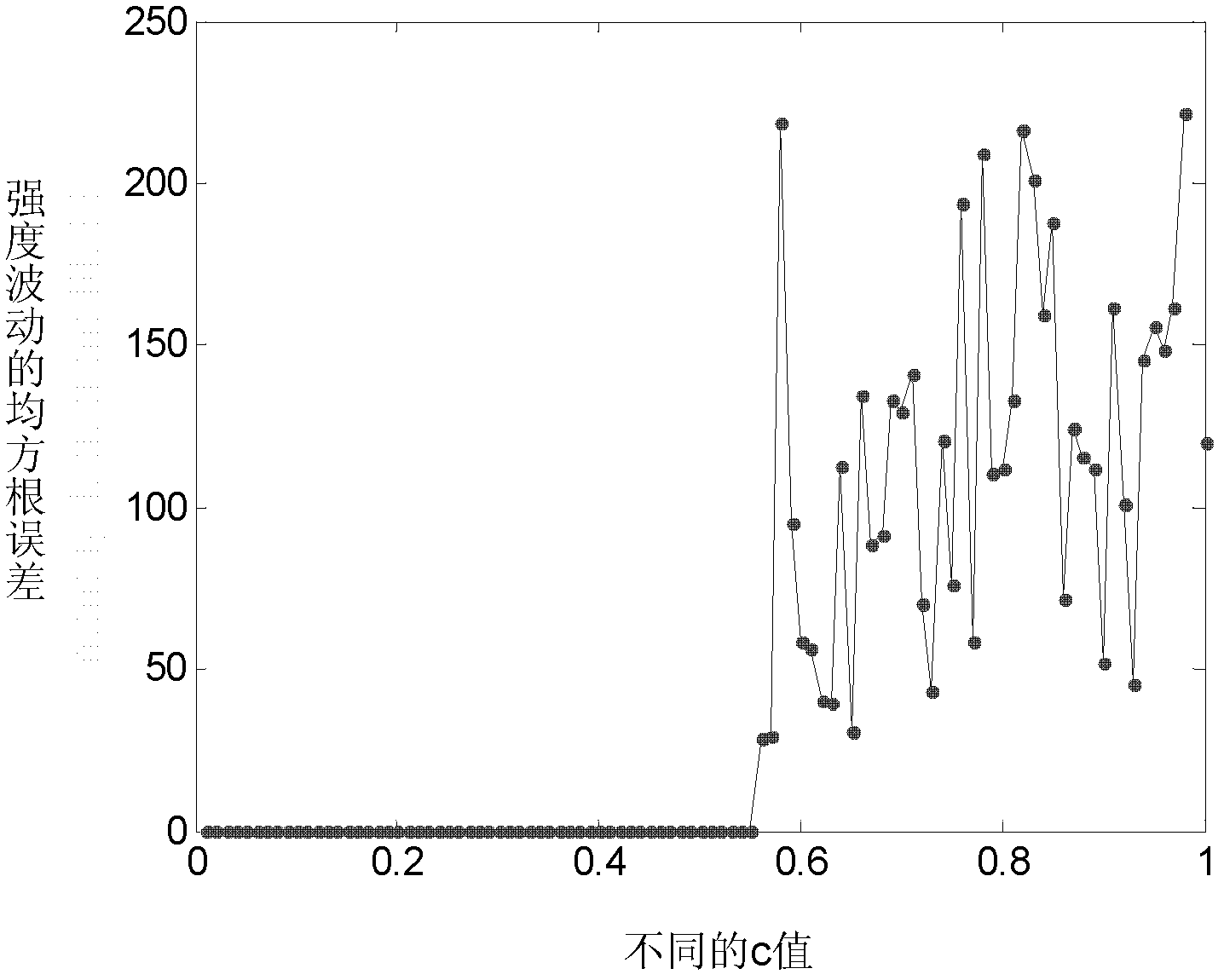

[0032] 2. φ of Step 1 1 According to the formula (2) to get U k , the phase distribution Ф of the output surface 3 is calculated by the fast Fourier transform of the lens 2 k , calculate the actually obtained intensity distribution I of the output surface 3 accor...

specific Embodiment approach 3

[0047] Embodiment 3. The difference between this embodiment and Embodiment 1 is that the focal length f can be achieved by superimposing the lens phase distribution on the optical phased array and the lens 2 in the device to form a combined focal length to achieve axial zooming, thereby achieving axial zooming. The purpose of outputting the intensity distribution of the shaped beam at a given position; by artificially setting the expected intensity distribution of the shaped beam as the shape and aperture of IT, a flat-hat beam of corresponding shape and aperture can be obtained at the output surface 3 position.

[0048] This implementation mode can reach the position where the far field can be set artificially, and realize any given shape of the laser beam and the flat-hat beam shaping characteristic of a given caliber.

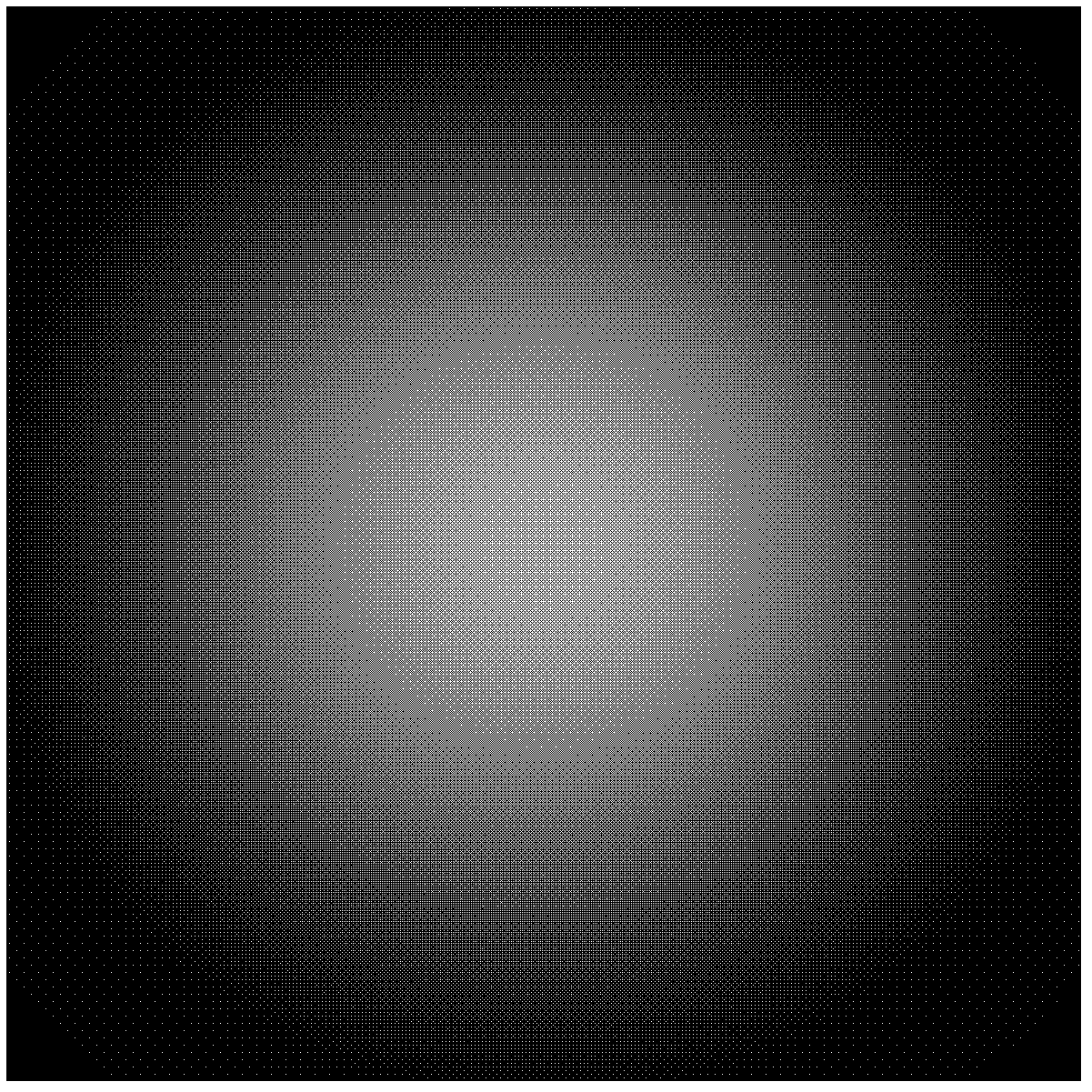

[0049] The incident light source is a laser with a wavelength of λ, and its beam intensity distribution can be expressed as:

[0050] I Gauss =exp[-2(x 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com