Cascading gain self-scheduling PID (Proportion Integration Differentiation) controller

A self-scheduling and controller technology, applied in electric controllers, controllers with specific characteristics, etc., to achieve the effect of shortening transition time, improving robustness, and reducing dynamic and static deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

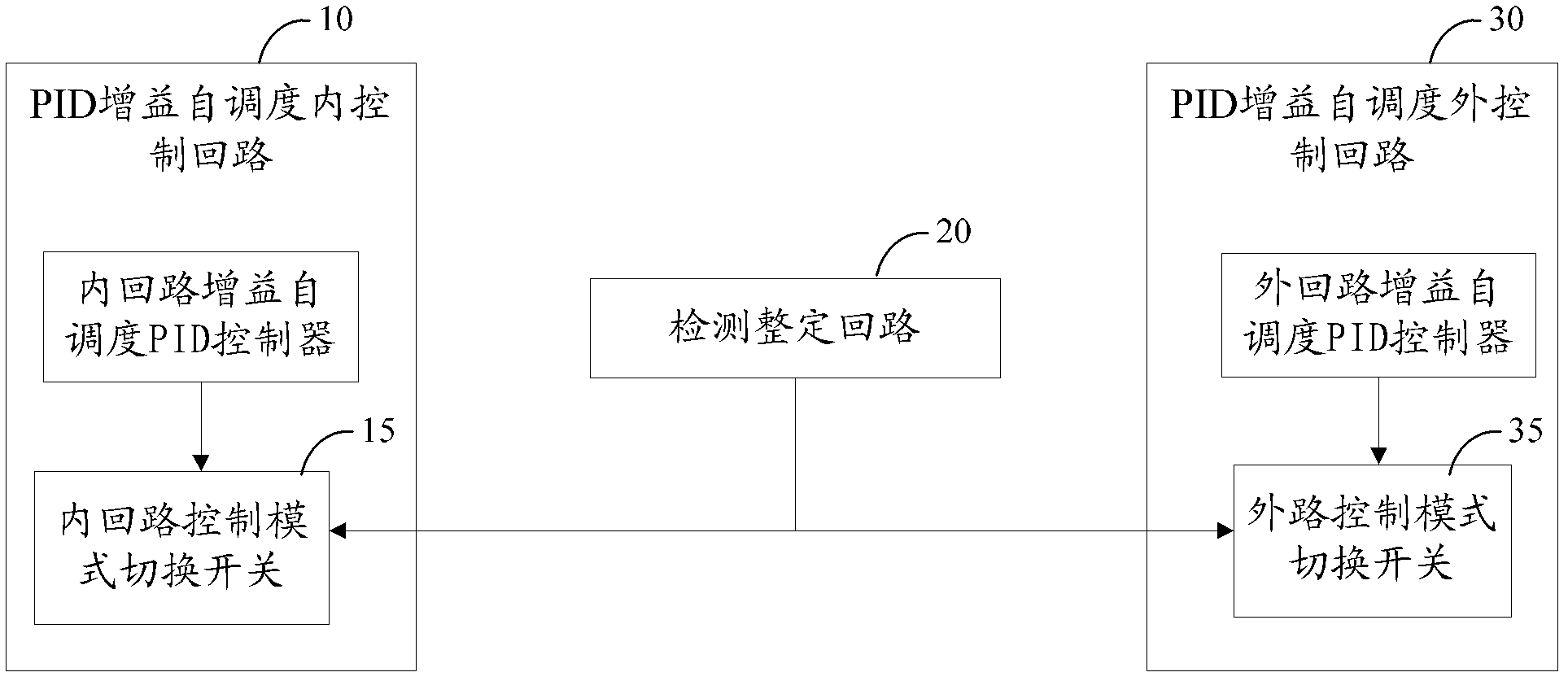

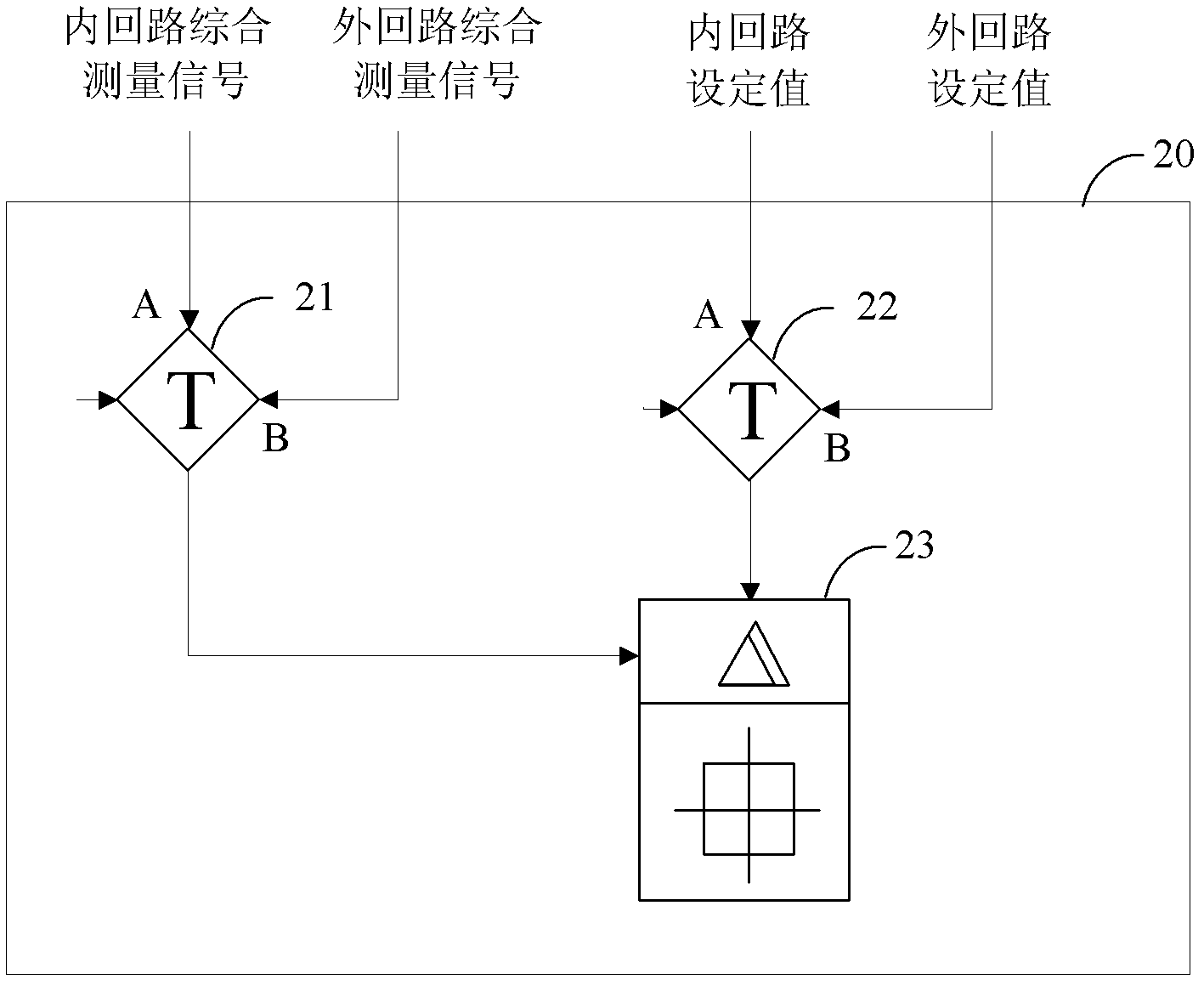

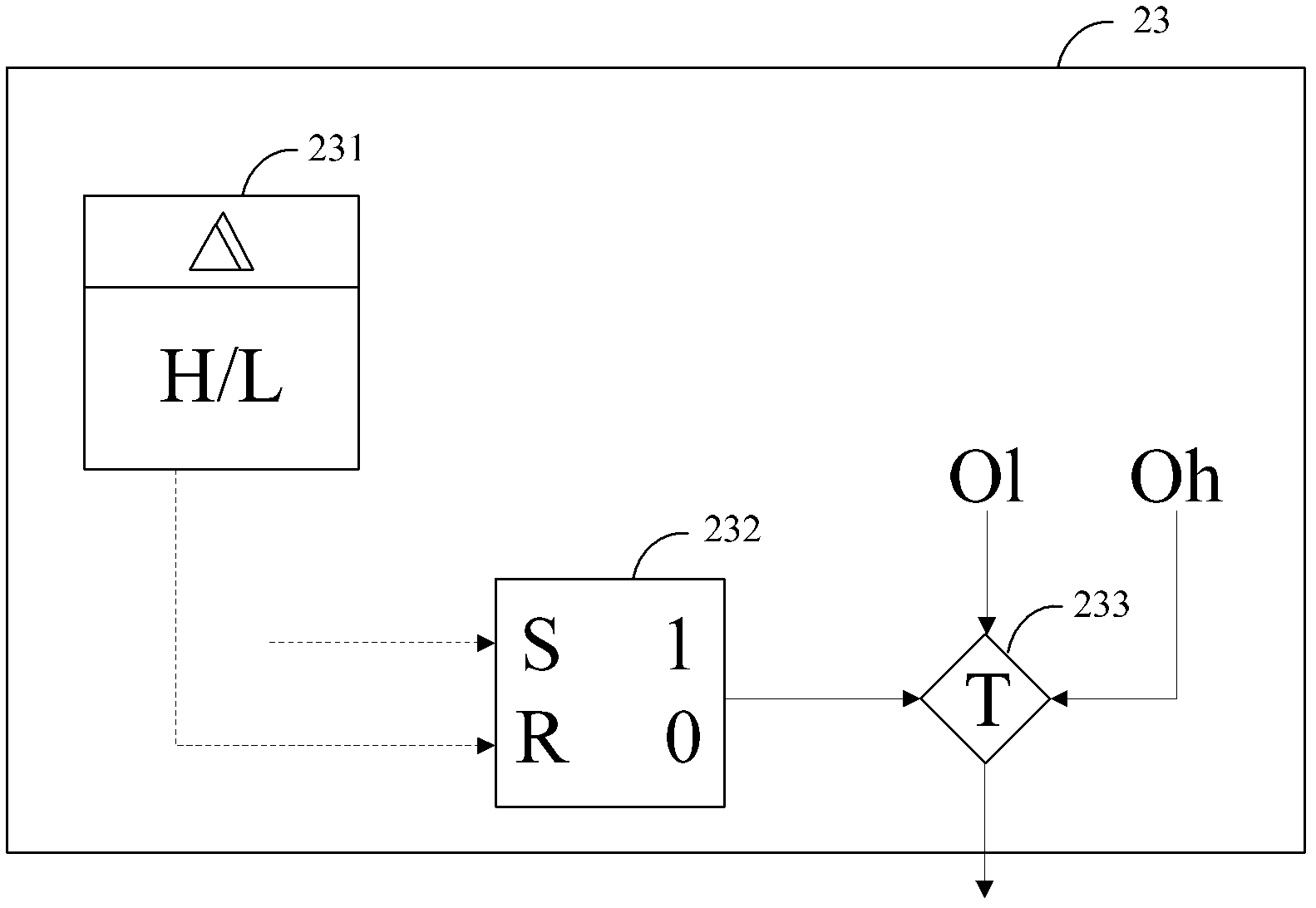

[0013] see figure 1 , figure 1 It is a simplified structural diagram of the cascade gain self-scheduling PID controller of the present invention.

[0014] The cascade gain self-scheduling PID controller includes: a PID gain self-scheduling inner control loop 10, a detection and tuning loop 20 and a PID gain self-scheduling outer control loop 30, and the detection and tuning loop 20 is respectively connected to the PID gain self-scheduling Inner control loop 10 and said PID gain self-scheduling outer control loop 30;

[0015] The PID gain self-scheduling inner control loop 10 includes an inner loop PID gain self-scheduling controller and an inner loop control mode switch 15, and the input end of the inner loop control mode switch 15 is connected to the inner loop PID gain self-scheduling control The output terminal of the device, its control terminal is connected to the output terminal of the detection and setting loop 20;

[0016] The PID gain self-scheduling outer control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com