Numerical control code converting method

A technology of numerical control code, conversion method, applied in the field of conversion, can solve the problems of three-dimensional model distortion, lack of numerical control interpreter consideration, lack of effective and unified representation of information and knowledge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, the present invention will be described in further detail based on the embodiments.

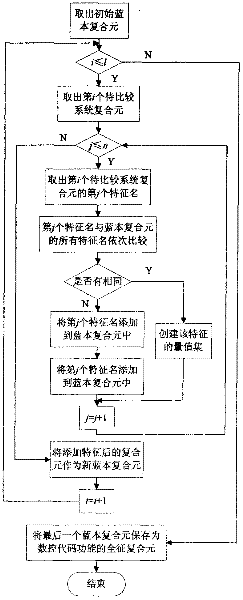

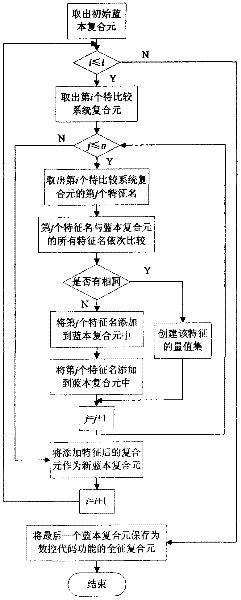

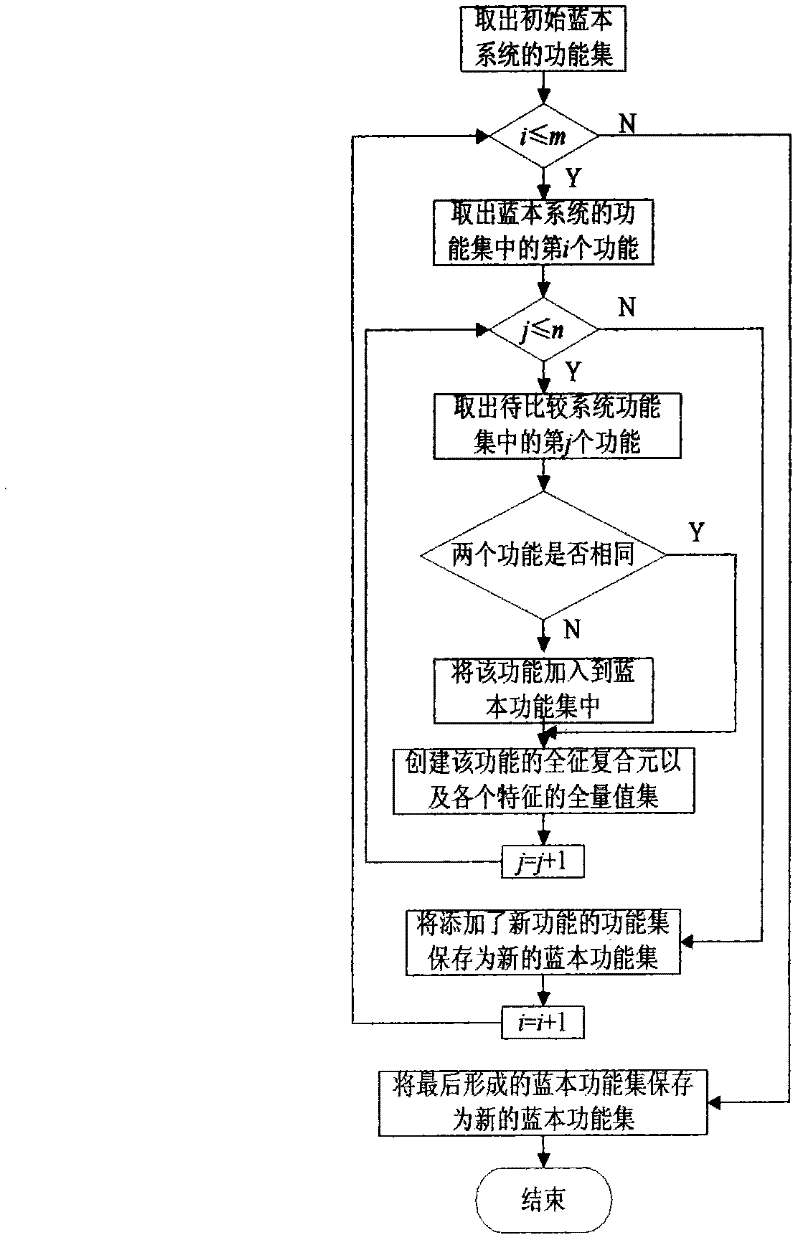

[0066] Process flow and manufacturing method

[0067] (1) Based on the primitive theory of extension theory and its divergence principle, establish an information model to express the information and data contained in the NC code.

[0068] According to the requirements of CNC code conversion, the common features of the basic nature of the machine tool: system manufacturer name, machine tool system series name, applicable processing method, machine tool coordinate system, axis and axis linkage, machining accuracy, etc., establish their information model ——Composite element of basic properties of machine tool, see formula 1.

[0069]

[0070] among them

[0071] Value of "Coordinate System":

[0072] Value of "Number of Axes and Coupling Condition":

[0073] In the "number of axes and coupling conditions", the value of "workpiece branch axis" (v 2 ) Can be represented by the matrix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com