Equipment for automatically cutting and detecting appearance and electric property of light-emitting diode (LED) lamp semi-finished products

A technology for inspecting equipment and semi-finished products, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as poor product quality control, low production efficiency, and low production efficiency, so as to improve work efficiency and cut quality, reduce production costs and labor The effect of strength and simple structure of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

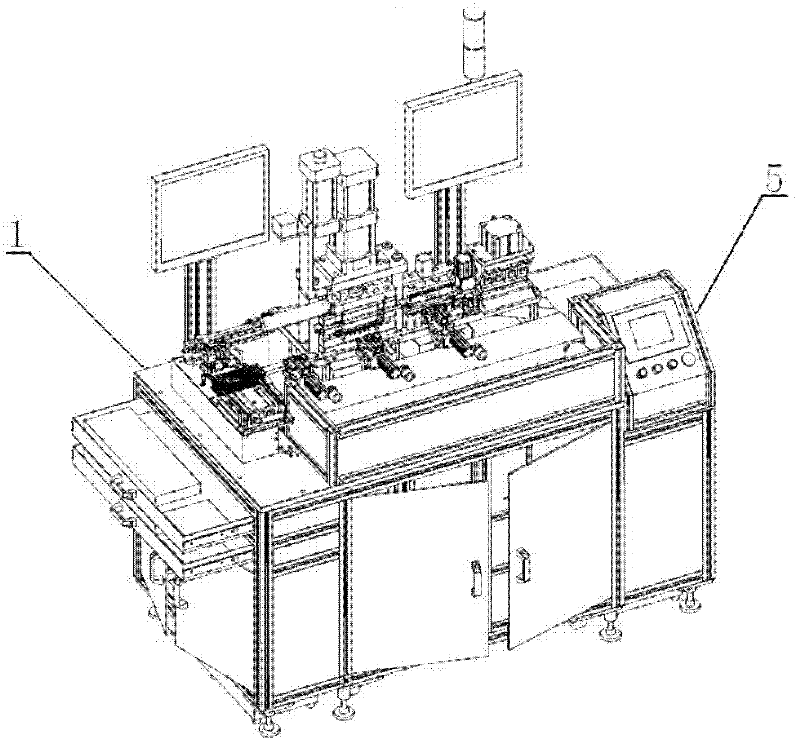

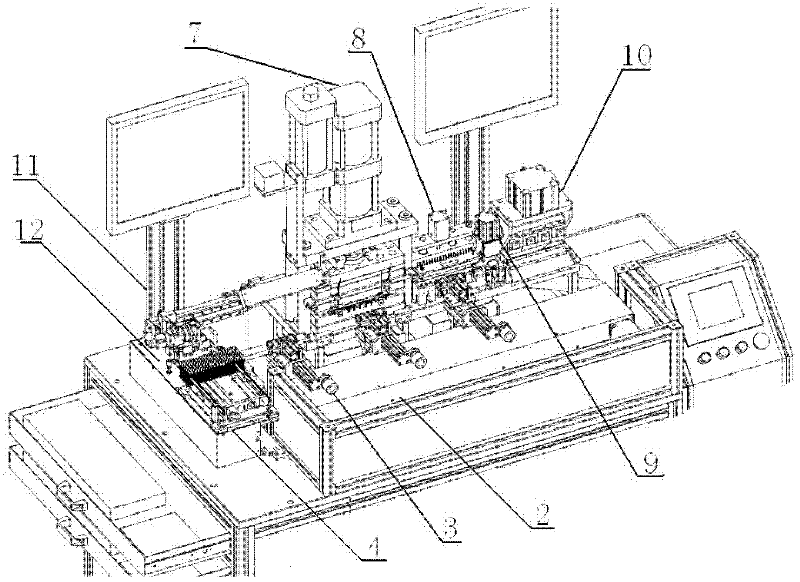

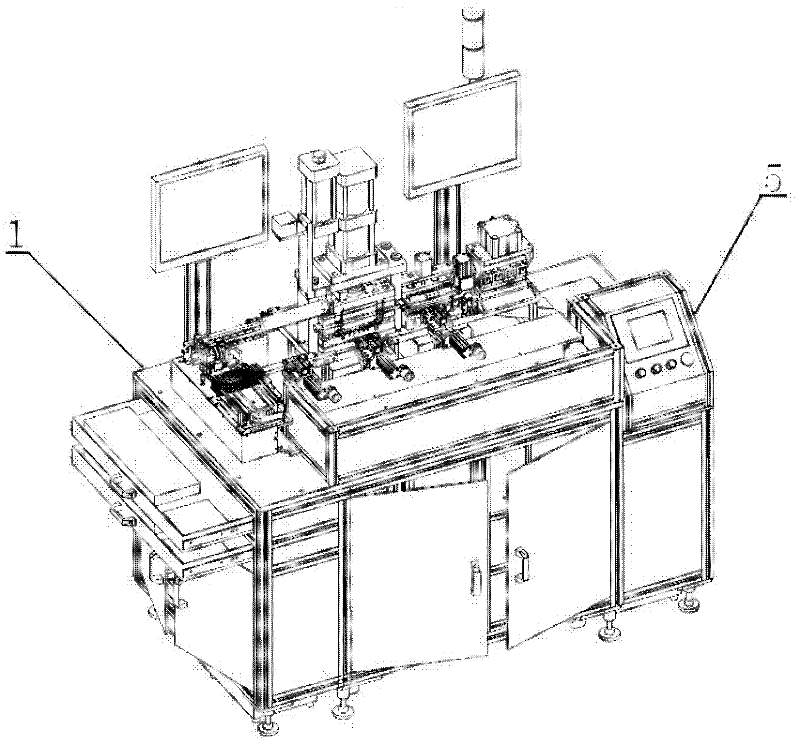

[0015] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the LED lamp semi-finished product automatic cutting and appearance and electrical inspection equipment proposed according to the present invention is described in detail below in conjunction with the accompanying drawings:

[0016] see figure 1 , when using the present invention to produce LED lamp semi-finished products, the semi-finished products are positioned by the motor through the magnetic pick-up device 12, and after the magnetic pick-up of the LED bracket, it passes through the rotating device 4 and enters the CCD visual inspection system 11 after being rotated 90 degrees, and the semi-finished products have poor appearance and manual marking. Identify and detect the information, send it to the operating system 5, judge the position of defective products and good products and store them; finally, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com