Adjustable metamaterial based on working frequency and production method thereof

A technology of working frequency and metamaterials, applied in the field of metamaterials, can solve problems such as complex preparation and processing procedures and poor tuning functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method based on a metamaterial with adjustable working frequency, the preparation method comprises the following steps:

[0027] S1: Clean and dry the selected substrate 1, which is made of thermoplastic polymer material with low dielectric constant, such as ABS;

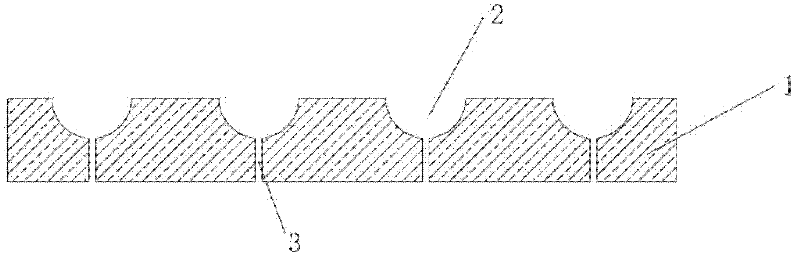

[0028] S2: Etch an array of grooves 2 on the substrate, and at the same time etch micropores 3 connected to the outside on the inner wall of each groove, such as figure 1 As shown, the diameter of the groove 2 is determined by the design of the main operating frequency of the actually required metamaterial;

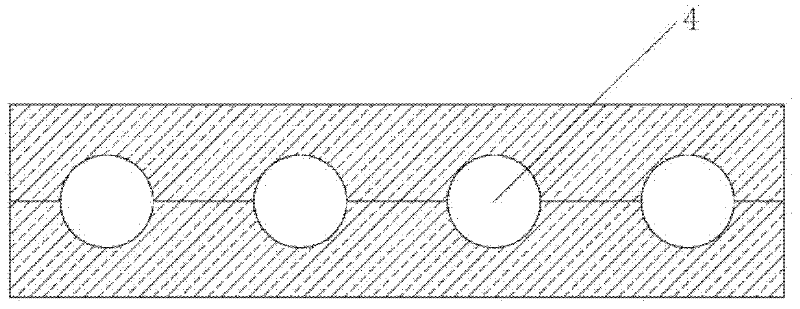

[0029] S3: The two substrates 1 etched with the array of grooves 2 are relatively bonded, and the grooves are combined to form a microstructure cavity 4. The cavity is spherical, ellipsoidal, cubic, cuboid, or cylindrical. body or any desired shape;

[0030] S4: inject liquid crystal with high dielectric constant into the microstructure cavity 4 through micropores, and seal the micropores...

Embodiment 1

[0034] S1: Clean and dry the selected substrate;

[0035] S2: Etch a hemispherical groove array with a diameter of 3 mm on the substrate, and at the same time etch a microhole connected to the outside on the inner wall of each groove;

[0036] S3: bonding the two substrates etched with groove arrays relative to each other, so that the grooves are merged to form a hollow spherical cavity;

[0037] S4: Inject liquid crystal with high dielectric constant into the hollow spherical cavity through micropores, and seal the micropores with resin to obtain a two-dimensional metamaterial.

[0038] Among them, since the microstructure is a liquid crystal material, and the dielectric constant of the liquid crystal is sensitive to temperature and electric field, when the external temperature or electric field changes, the dielectric constant of the liquid crystal also changes accordingly, making the operating frequency of the metamaterial The range becomes wider, which expands the applica...

Embodiment 2

[0040] S1: Clean and dry the selected substrate;

[0041] S2: Etch a hemispherical groove array with a diameter of 3 mm on the substrate, and at the same time etch a microhole connected to the outside on the inner wall of each groove;

[0042] S3: bonding the two substrates etched with groove arrays relative to each other, so that the grooves are merged to form a hollow spherical cavity;

[0043] S4: Inject liquid crystal with high dielectric constant into the hollow spherical cavity through micropores, and seal the micropores with resin to obtain a two-dimensional metamaterial.

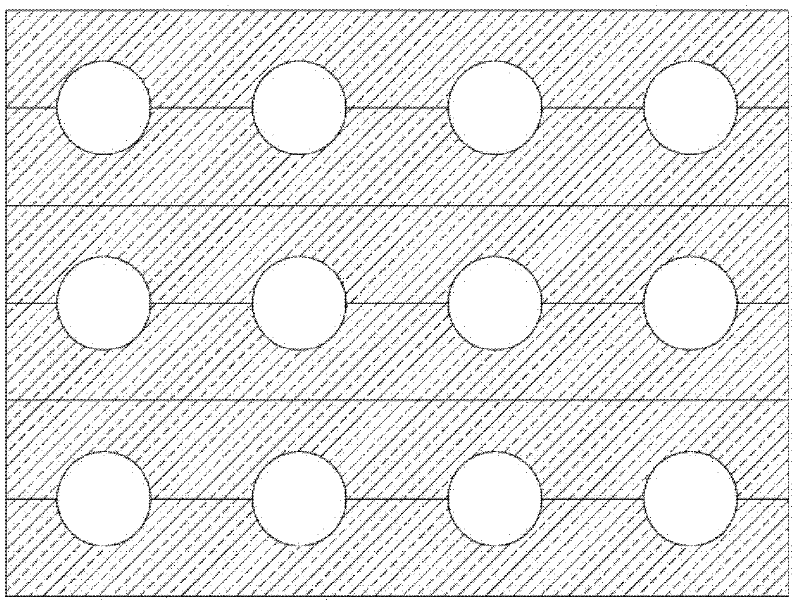

[0044] S5: The multi-layer two-dimensional metamaterial is mechanically fixed, and the edge of each layer of two-dimensional metamaterial is aligned and fixed to obtain a three-dimensional metamaterial.

[0045] Embodiment 2 Compared with Embodiment 1, multiple two-dimensional metamaterials are fixed to make three-dimensional metamaterials, which expands the application range of metamaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com