Epitaxial structure of gallium nitride based laser device and manufacturing method of epitaxial structure

A gallium nitride-based, epitaxial structure technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of reducing laser performance, increasing laser light absorption, etc., to reduce non-radiative recombination and carrier absorption, The effect of reducing the polarization electric field and reducing the accumulation of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

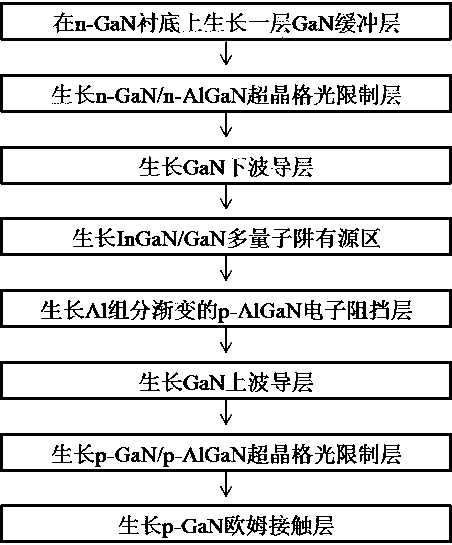

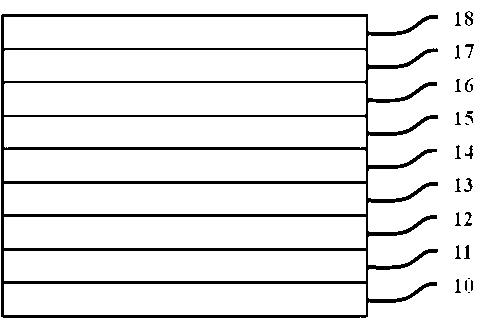

[0033] see Figure 1~3 As shown, a method for preparing a GaN-based laser epitaxial structure includes the following steps:

[0034] (a) epitaxially grow a GaN buffer layer on the n-GaN substrate;

[0035] (b) Epitaxial growth of n-GaN / n-AlGaN superlattice n-type optical confinement layer on the buffer layer;

[0036] (c) Growth of undoped GaN lower waveguide layer;

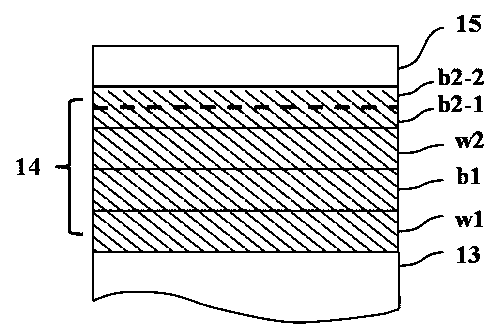

[0037] (d) Growth of InGaN / GaN quantum well active region;

[0038] (e) Growth of Al with graded Al composition x Ga 1-x N electron blocking layer;

[0039] (f) growing an undoped GaN upper waveguide layer;

[0040] (g) Growth of p-GaN / p-AlGaN superlattice p-type optical confinement layer;

[0041] (h) Growth of p-GaN ohmic contact layer.

[0042] After the step (h), it further includes: using inductively coupled plasma (ICP) to etch a laser ridge structure; using electron beam evaporation or magnetron sputtering to deposit a layer of dielectric film on the surface of the top p-GaN contact layer As a lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com